| –

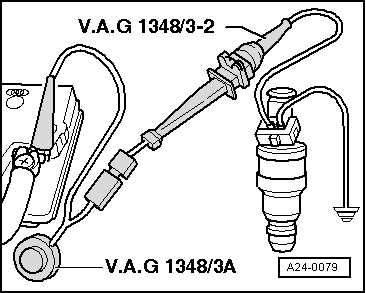

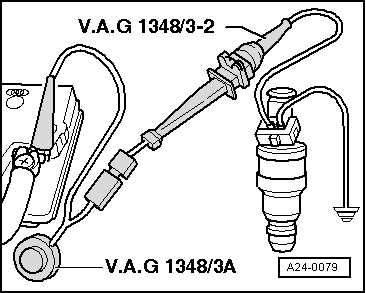

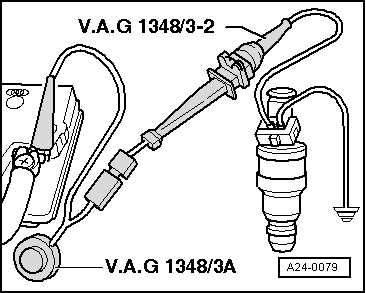

| Lay a contact of the injection valve with the test cable and alligator clip from the adapter cable set -V.A.G 1594 A- on the engine mass. |

| –

| Connect the other contact of the injection valve with remote control -V.A.G 1348/3 A -, adapter cable -V.A.G 1348/3-2- and auxiliary cable to battery positive. |

| –

| Initiate an actuator diagnosis and select the activated charcoal filter solenoid valve 1 -N80- → Chapter. The fuel pump runs for approx. 50 s. |

| –

| Test the tightness of the injectors (visual inspection). With the fuel pump running per valve only 1...2 drops (50 s) of fuel may escape. |

| –

| If the fuel loss is greater adjust the fuel pump (end final control diagnosis) and replace defective injector. |

| –

| Initiate again an actuator diagnosis and select the activated charcoal filter solenoid valve 1 -N80-. |

Note | The final control diagnosis can only be initiated again after the ignition has been briefly switched off. |

| –

| Operate the remote control for 30 seconds immediately after selecting the ACF valve (the fuel pump is switched on for approx. 50 s) -V.A.G 1348/3 A-. |

| –

| Perform the measurement on all injection valves (initiate again an actuator diagnosis). |

| –

| Once all four injectors have been driven, position the graduated measuring glasses on an even base. |

| Specified value: 85 up to 105 ml. |

| –

| If the measured value of one or more injectors is outside the tolerance value, disconnect the fuel pump (terminate final control diagnosis) and replace the defective injector. |

| –

| If the measured values are outside tolerance for all injectors, check fuel pressure → Chapter. |

Note | When testing the injection rate also check the jet formation. The jet must be the same for all injection valves. |

| The installation of the fuel distributor with the injection valves occurs in reverse order. To do so, pay attention to the following points: |

| l

| Replace “O” rings on all opened connection points. (For replacing the front “O” ring, on no account remove the plastic valve head cap - lift the “O” ring over the plastic cap). |

| l

| Moisten “O” rings with clean engine oil. |

| l

| Pay attention to correct positioning of the injectors. |

| l

| Check perfect fit of the retaining clips. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note