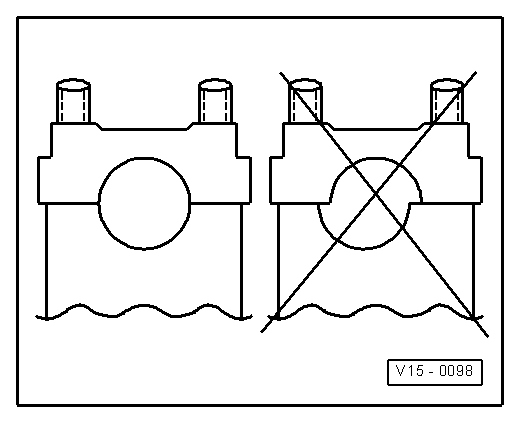

Note | Cylinder heads with cracks between the valve seats may be continue to be used without any reduction in the life time provided the cracks are slight and max. 0.5 mm wide. |

| –

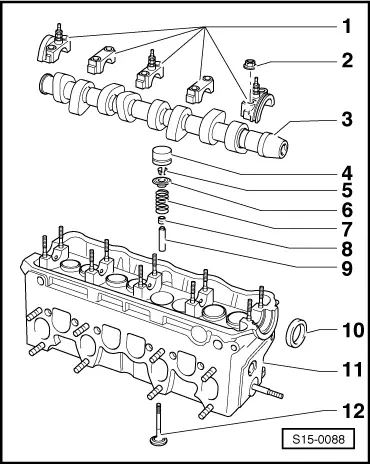

| Seal the contact surface of bearing caps 1 and 5 with sealant -AMV 174 004 01-. |

| –

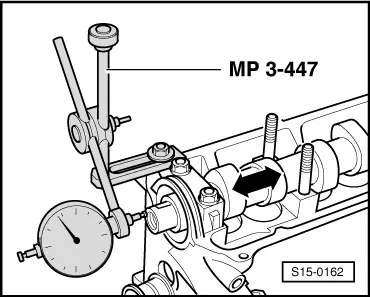

| Inspecting axial play → Fig. |

| –

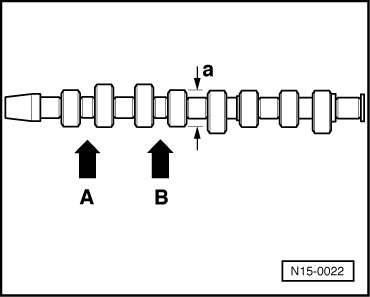

| Camshaft identification → Fig. |

| –

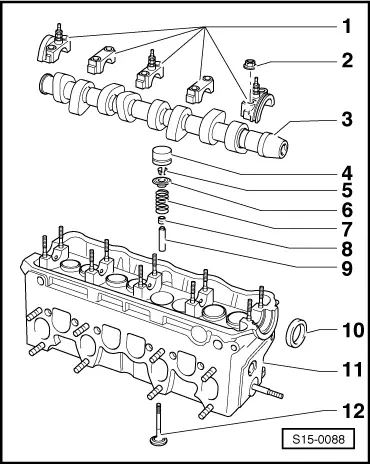

| with hydraulic valve clearance compensation |

| –

| lay aside with contact surface facing down |

| –

| before installing check axial play of the camshaft → Fig. |

| 6 - | Valve spring retainer |

| –

| removing and installing: cylinder head removed: with -MP 1-218 -, -MP 1-211- and -MP 1-213 -, cylinder head installed: → Chapter |

| –

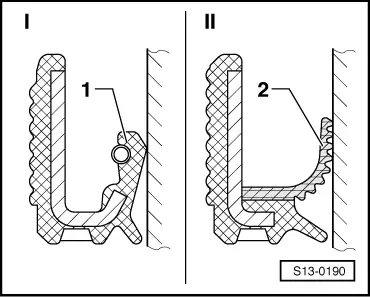

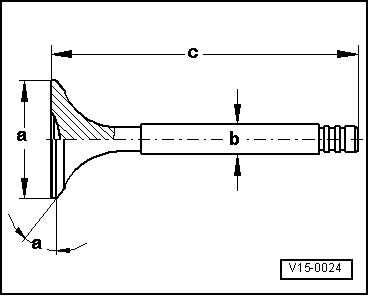

| pay attention to different version → Fig. |

| –

| to remove and install, the bearing cap and the toothed belt gear must be removed |

| –

| before fitting cover slot on the camshaft cone with commercially available adhesive tape (e.g. Scotch tape). |

| –

| Removing and installing timing belt → Chapter |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note