| –

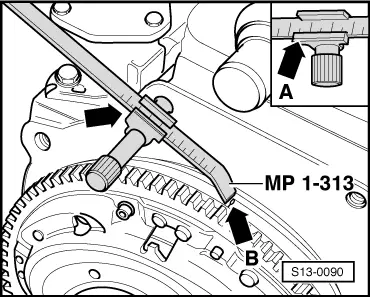

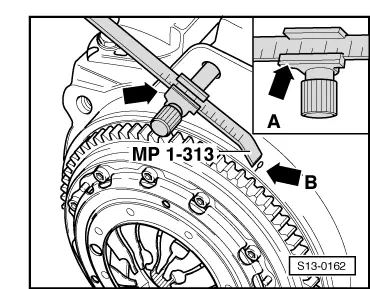

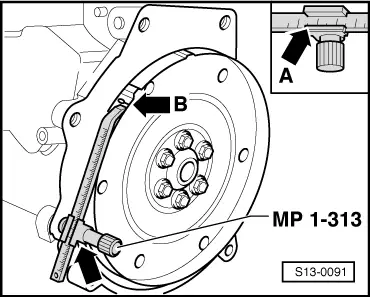

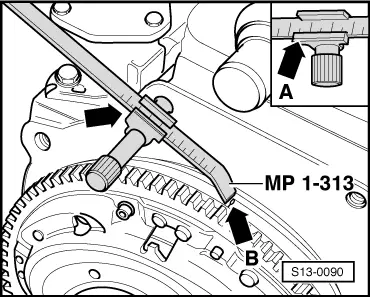

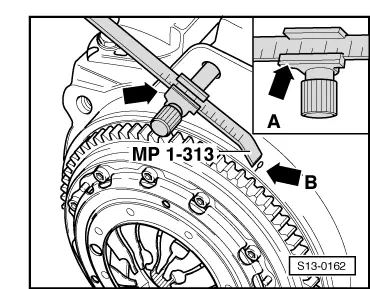

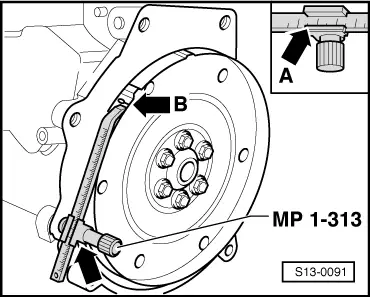

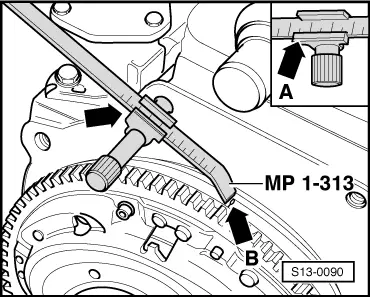

| Screw in adjusting device for TDC point -MP 1-313-, as shown in the fig. |

| –

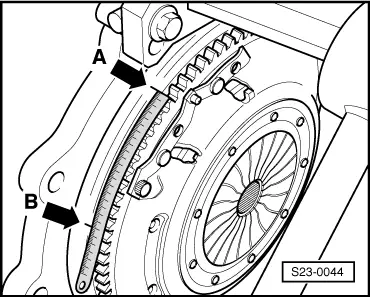

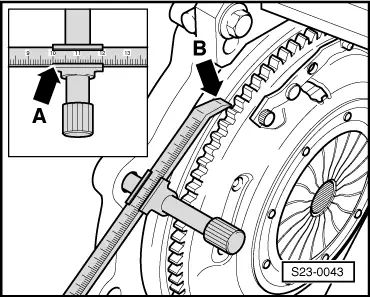

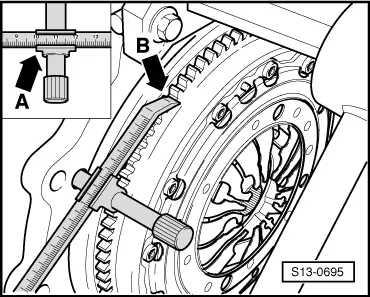

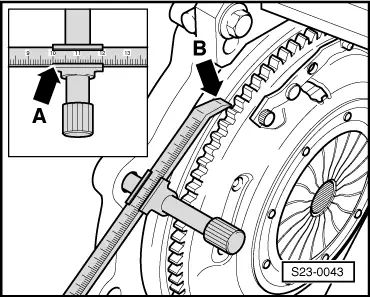

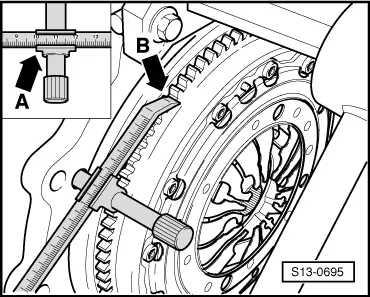

| Set adjusting device to 96 mm -arrow- (the left notch on the vernier -arrow A- is the reference point). |

| –

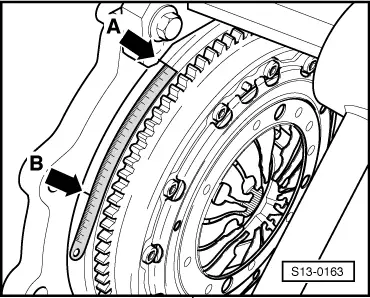

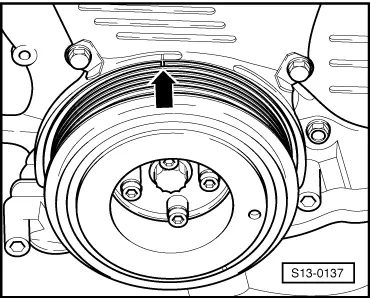

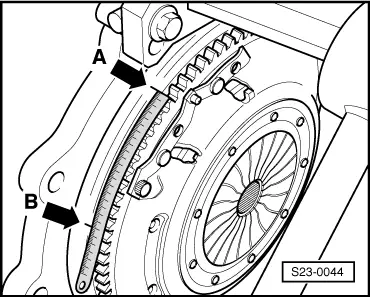

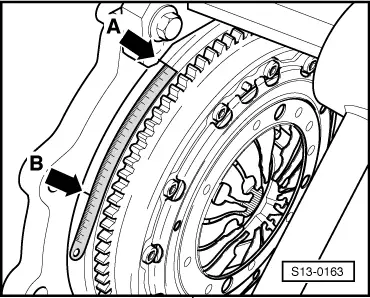

| Rotate crankshaft until the TDC marking -arrow B- on the flywheel corresponds with the edge of the adjusting device. |

|

|

|