| t

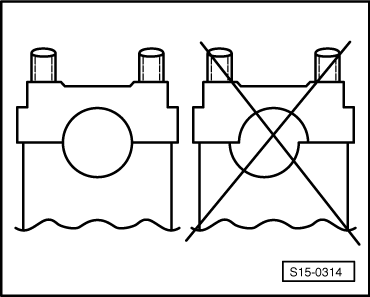

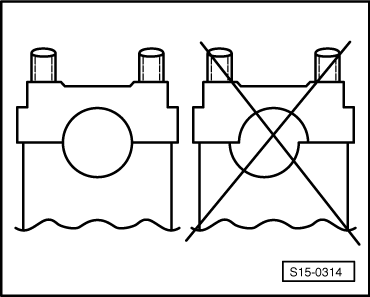

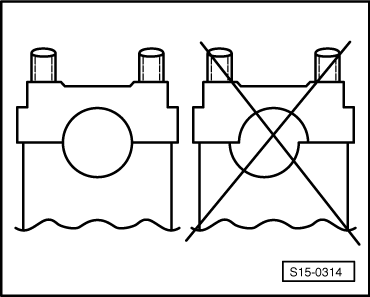

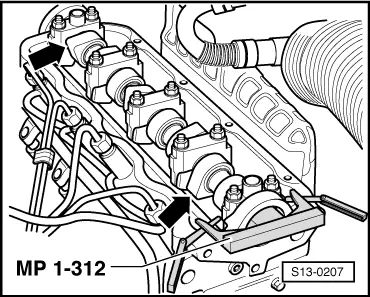

| When installing the bearing caps pay attention to the centre displacement of the bore, before installing insert bearing cap and determine fitting position. |

| –

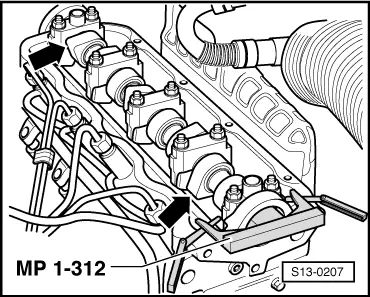

| Oil contact surfaces of camshaft. |

| –

| Tighten bearing caps 2 and 4 alternately crosswise to 20 Nm. |

| –

| Install bearing caps 5, 1 and 3 and also tighten to 20 Nm. |

| –

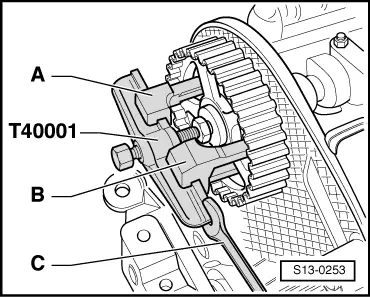

| Position camshaft sprocket and tighten by hand. |

Note | t

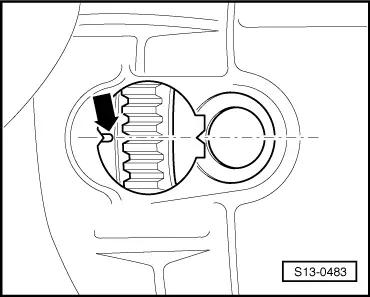

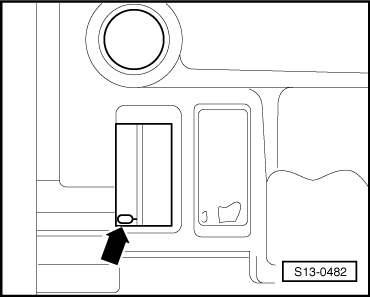

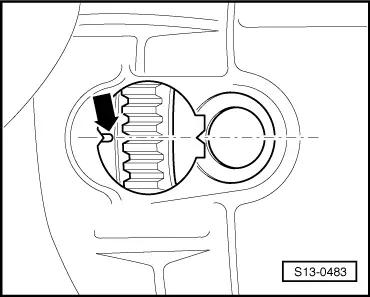

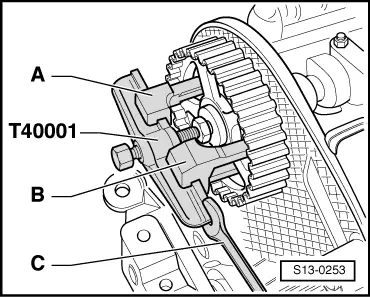

| If new hydraulic tappets are installed, the engine must not be started for about 30 minutes. The hydraulic clearance compensation elements must “settle” (otherwise valves would strike the pistons). |

| t

| After carrying out work on the valve gear, carefully crank engine at least 2 revolutions to ensure that no valve touches the piston when the engine is started. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note