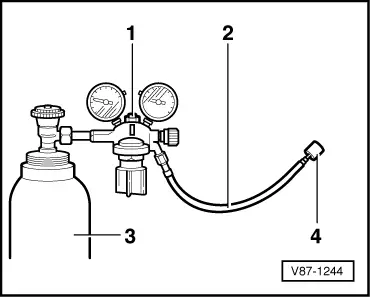

| Leak detection on the refrigerant circuit with compressed air or nitrogen |

| A major leak can be determined, for example, if a pressure of maximum 15 bar builts up in the refrigerant circuit with clean and dried compressed air or with nitrogen. |

Note | t

| If a major leak is suspected, do not fill the refrigerant circuit with the refrigerant R134a. |

| t

| If the leak is large enough, noise can be heard at the leak point which is produced by the escaping air or gas. |

|

|

|

Note

Note

Note

Note