| –

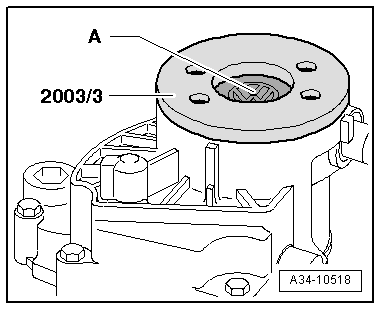

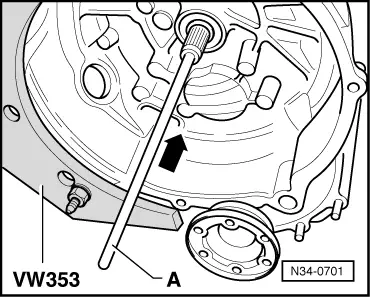

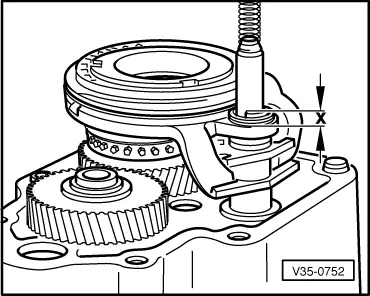

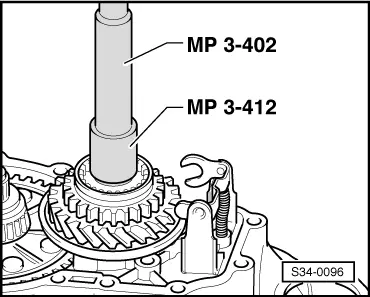

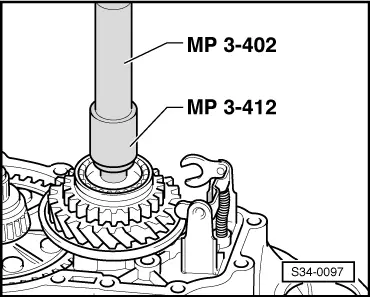

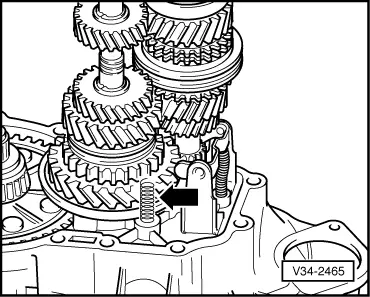

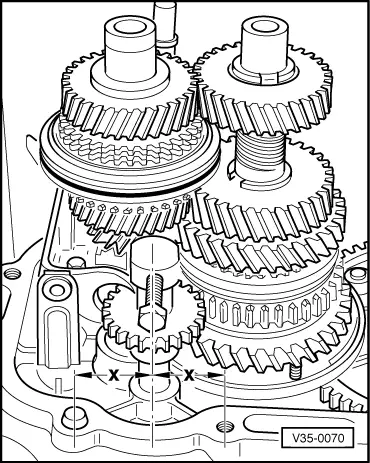

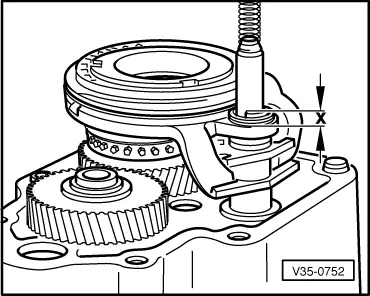

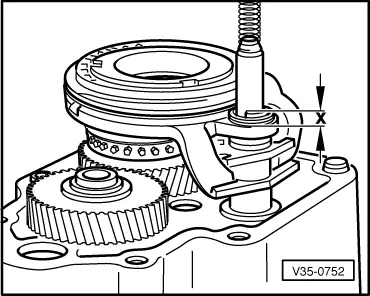

| Screw out shift tube so far until a projection -x- = 5.0 mm is reached. |

Note | Do not pull shift rod out of the shift tube (possibly through tilting of the pipe wrench), otherwise the shift forks in the gearbox come apart and the gearbox must be dismantled again. If necessary, hold down the shift rod with a screwdriver when removing the pipe wrench through the lateral slot. |

| –

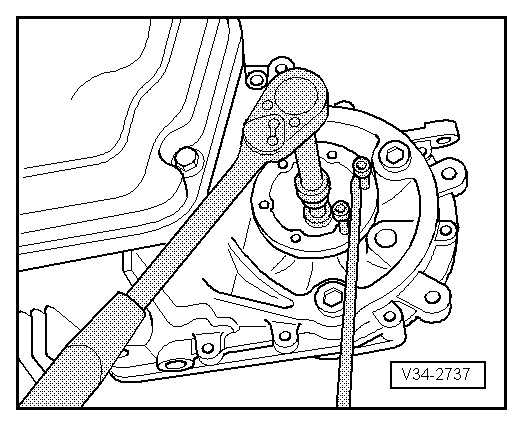

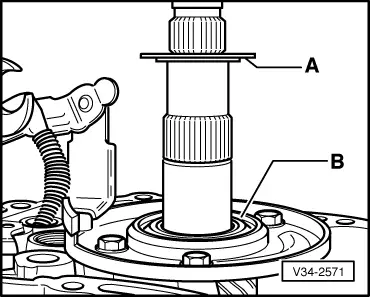

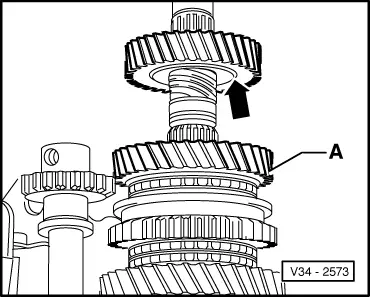

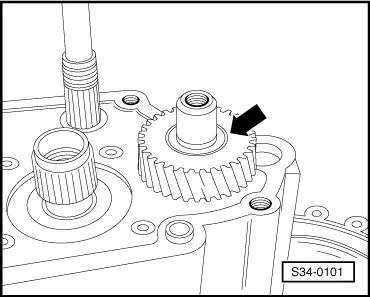

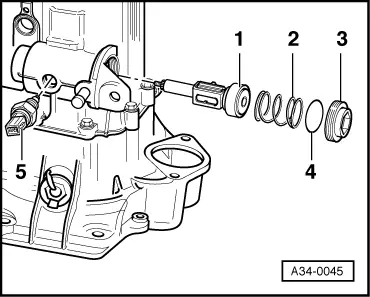

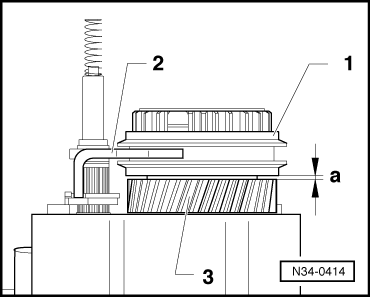

| Position new screw for synchronizer body with disc spring. |

| l

| The new screw must be micro encapsulated. If not, coat the screw with locking agent -D 000 600 A2-. |

| l

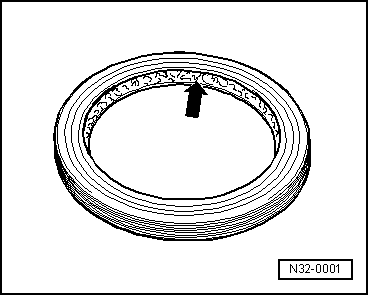

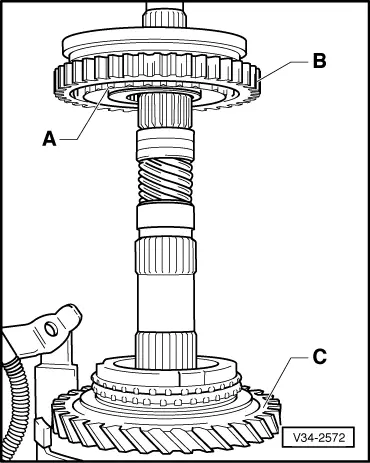

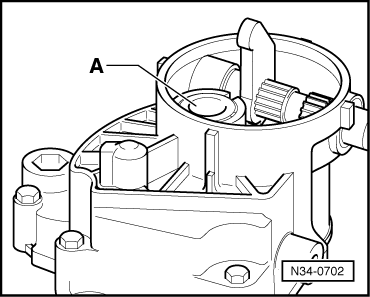

| Fitting position of the disc spring: the outside diameter (concave side) points to the 5th gear. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note