Octavia Mk1

Note

Note

|

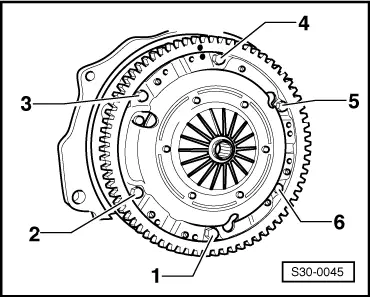

| 1 - | Flywheel |

| q | make sure the centering pins are tight |

| q | The locating face for the clutch lining must be free from grooves, oil and grease |

| q | removing and installing → Rep. Gr.13 |

| 2 - | Clutch disc |

| q | Diameter → Chapter |

| q | pay attention to correct installation position |

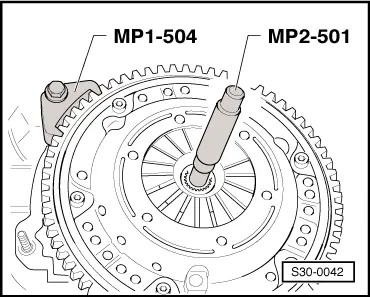

| q | center → Fig. |

| q | slightly grease the serration |

Note

Note| Clean the drive shaft serration and hub serration on used clutch discs. Remove corrosion and only apply a very thin layer of grease -G 000 100- on the drive shaft serration. Subsequently move the clutch disc up and down on the drive shaft until the hub fits smoothly on the shaft. Remove all excess grease. |

| 3 - | Pressure plate |

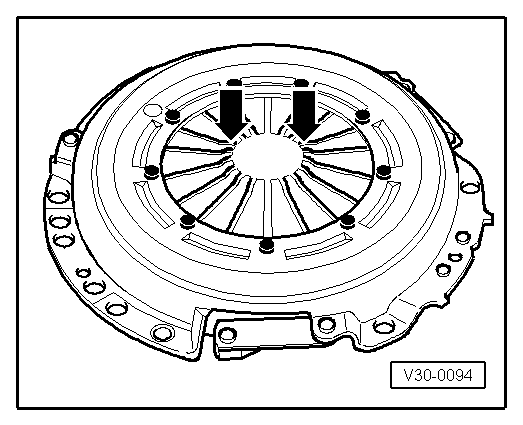

| q | removing and installing → Fig. |

| q | Check the extremities of the membrane spring → Fig. |

Note

Note| The pressure plates are protected against corrosion and are greased. Only clean the thrust surface as otherwise the life of the clutch may be considerably reduced. |

| 4 - | Lock washer |

| 5 - | Screw, 25 Nm |

| q | removing and installing → Fig. |

|

|

|

|