Octavia Mk1

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

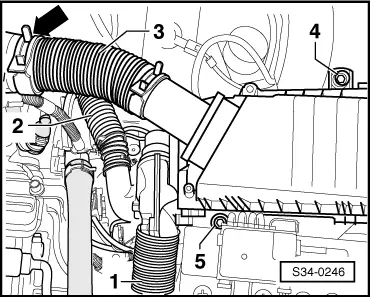

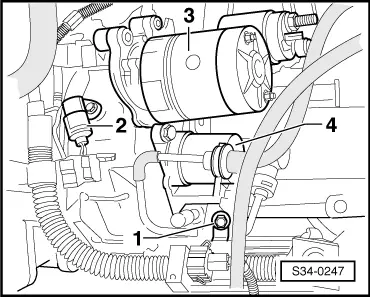

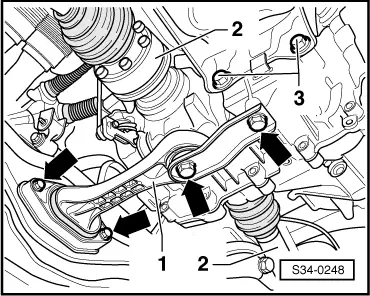

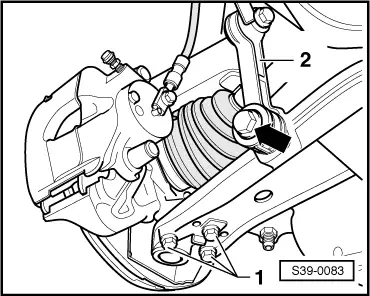

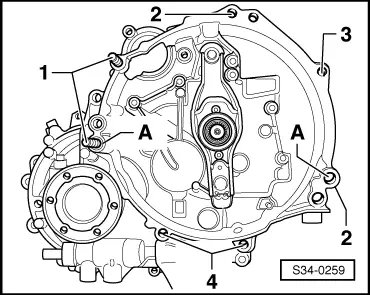

| Pos. | Nut/screw | Pieces | Nm |

| 1 | Nut M10 | 2 | 45 |

| 2 | Nut M10 | 2 | 45 |

| 3 → Note | Screw M10 | 1 | 45 |

| 4 | Screw M10 | 2 | 45 |

|

|

|

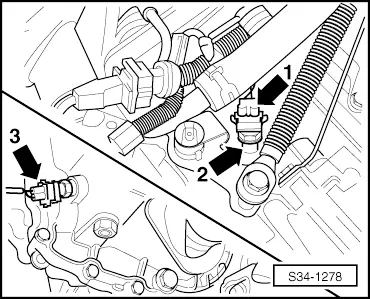

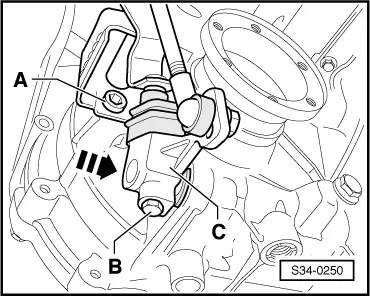

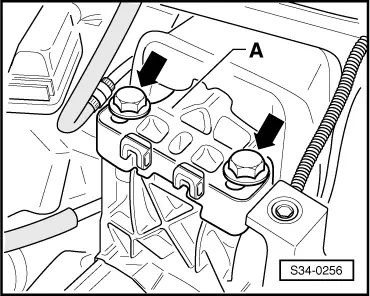

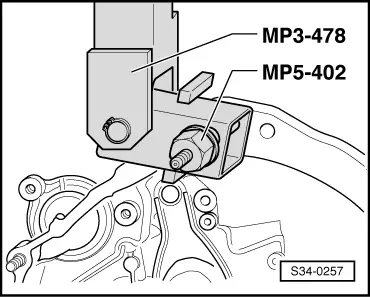

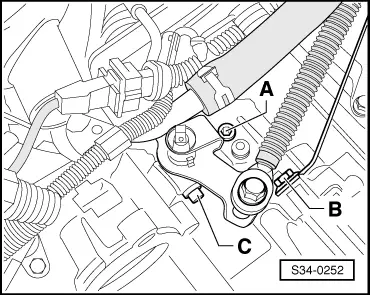

| Screw -A- for console and guide bush (speedometer) to gearbox | 20 Nm | |

| Screw -B- and -C- | 20 Nm | |

|

|

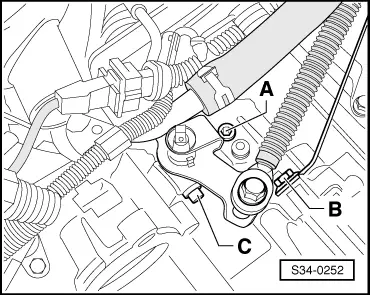

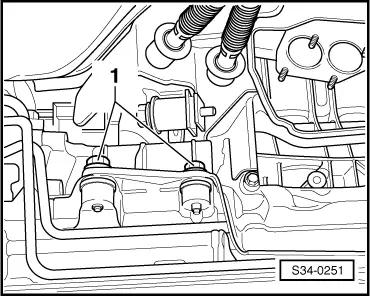

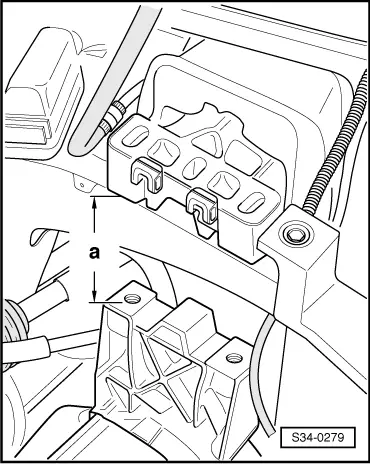

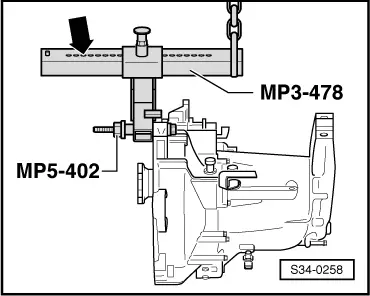

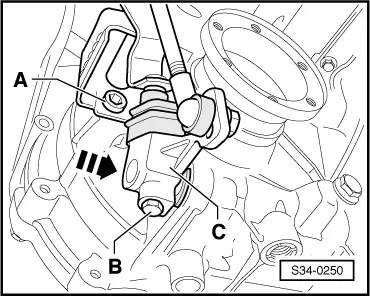

| Screw -A- | 20 Nm | |

| Screw -B- for attaching the gearbox shift lever -C- to the gearshift shaft → Note | 20 Nm | |

|

| Components | Tightening torque | |

| Support angle - steering gear M8 | 25 Nm | |

| Cover for gearbox housing - gearbox mount M12 → Note | 80 Nm | |

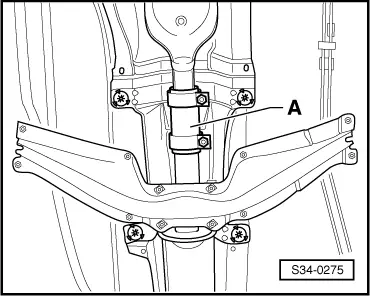

| Pendulum support - gearbox M10 → Note | 40 Nm + 90° | |

| Pendulum support - assembly carrier M8 → Note | 20 Nm + 90° | |

| Drive shaft - flange shaft (tighten crosswise in 2 stages) M8 → Note → Rep. Gr.40 | ||

| Steering joint - track control arm M8 → Note | 20 Nm + 90° | |

| Coupling rod - track control arm | 45 Nm | |

| Starter - gearbox M8 | 25 Nm | |

| Wheel bolts - wheel hub | 120 Nm | |

| Nut for attaching double clamp of exhaust system | 40 Nm | |

|