Octavia Mk1

Note

Note| The gearshift fork group (Pos. 7) does not have to be disassembled for the disassembly and assembly of the shift segments, clamping plates and angular ball bearings. |

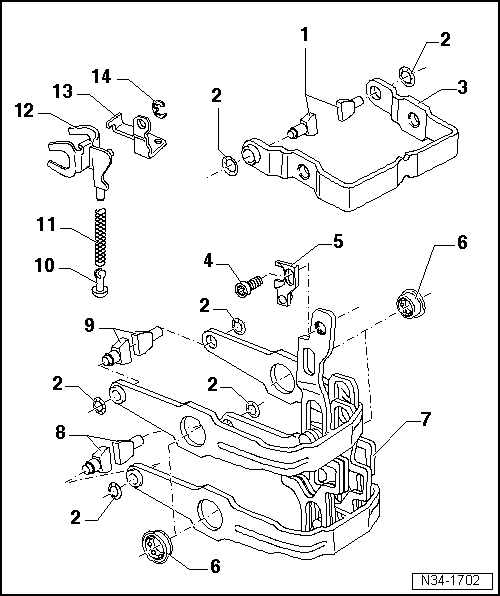

| 1 - | 5th gear shift segment |

| q | Identification → Fig. |

| q | It must still be possible to rotate the shift segment freely once the circlip has been fitted |

| 2 - | Circlip |

| q | always replace → Electronic Catalogue of Original Parts |

| q | removing → Fig. |

| q | installing → Fig. |

| 3 - | 5th gear shift fork |

| q | Setting 5th gear → Chapter |

| 4 - | 25 Nm |

| 5 - | 5th gear shift fork |

| 6 - | Angular ball bearing |

| q | 4 pieces |

| q | removing → Fig. |

| q | installing → Fig. |

| 7 - | Gearshift fork group with shift rails |

| 8 - | 1st/2nd gear shift segment |

| q | Identification → Fig. |

| q | It must still be possible to rotate the shift segment freely once the circlip has been fitted |

| 9 - | 3rd/4th gear shift segment |

| q | Identification → Fig. |

| q | It must still be possible to rotate the shift segment freely once the circlip has been fitted |

| 10 - | Sliding shoe |

| 11 - | Spring |

| 12 - | Gearshift fork reverse gear |

| 13 - | Support for reverse gear shift fork |

| 14 - | Circlip |

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

| Dimension -a- (mm) | |

| 1st/2nd gear shift fork up to 08.00 | 87,2 … 87,4 |

| 1st/2nd gear shift fork as of 09.00 | 88,4 … 89,1 |

| 3rd/4th gear shift fork | 93,6 … 93,8 |

|