| –

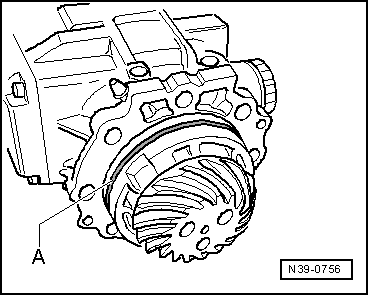

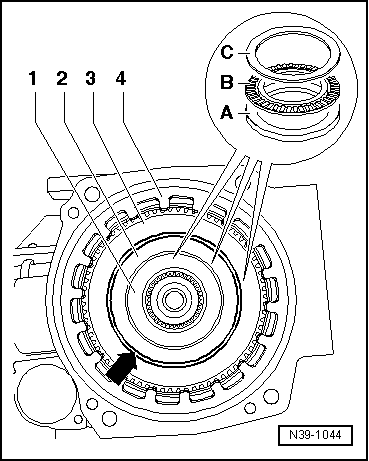

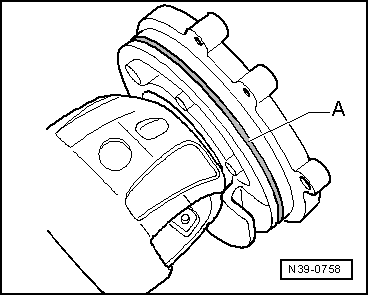

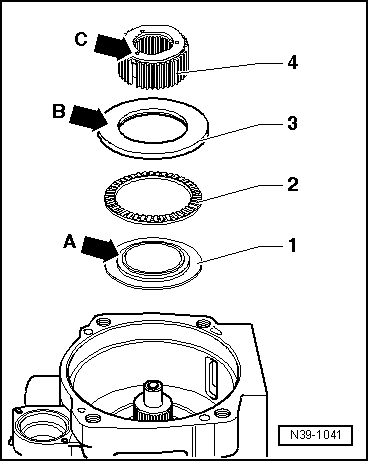

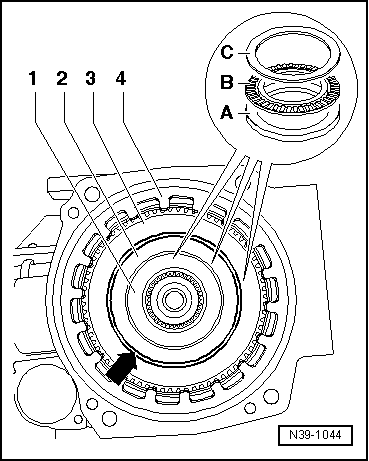

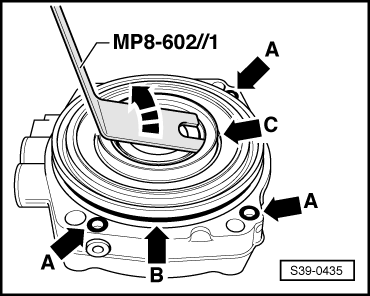

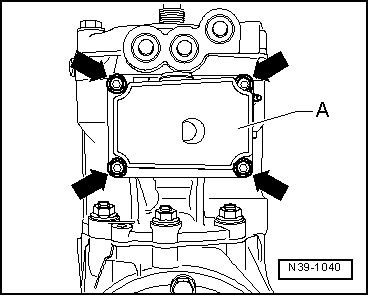

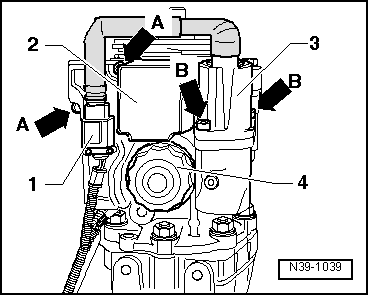

| Position the thicker thrust washers -A- onto the castors and rollers in the plate housing. |

| –

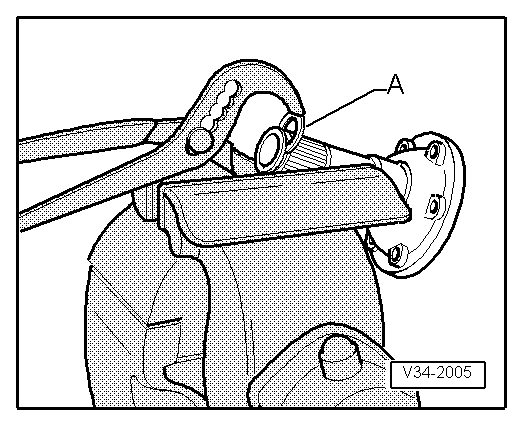

| After this, fit on the axial needle bearings -B- and the thinner thrust washers -C- for axial needle bearing. |

Note | t

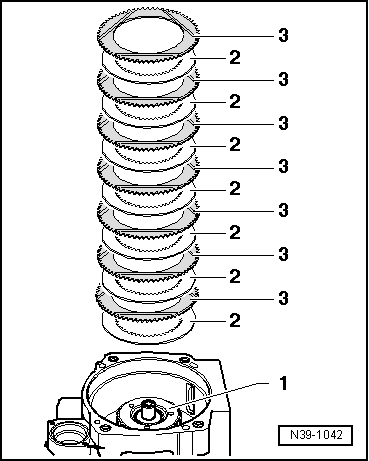

| These individual axial needle bearing packages 1 through 3 are assigned to the diameters of the pistons for Haldex coupling. |

| t

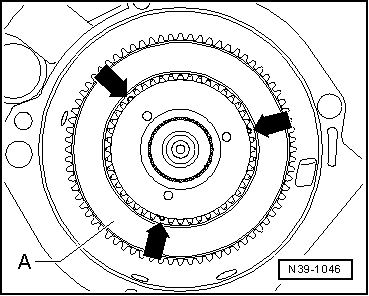

| Make sure that the gap -arrow- between the axial needle bearing packages 2 and 3 is of equal size all around. |

| –

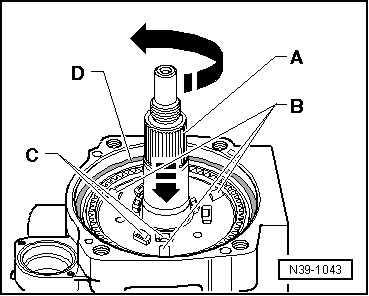

| Insert the disc spring -4- with the large Ø (concave side) pointing towards the ring ( → Anchor, fig. N39-1043). |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note