| –

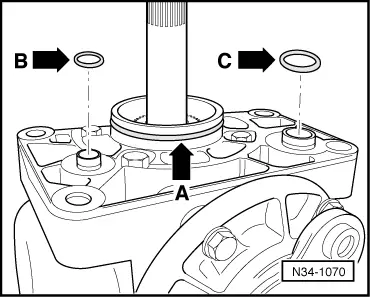

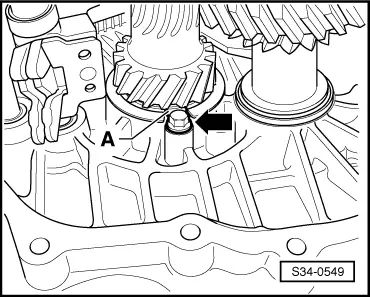

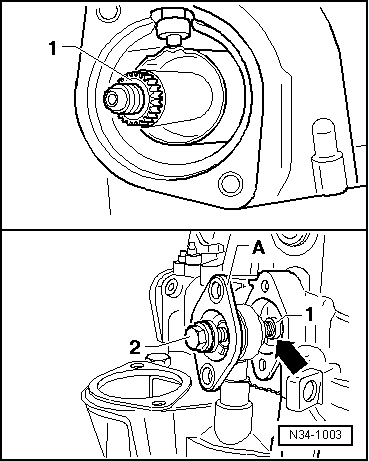

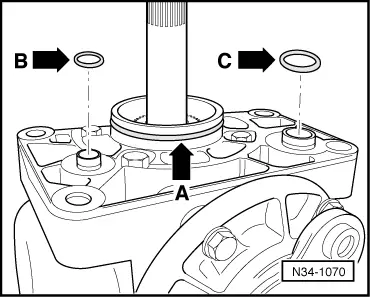

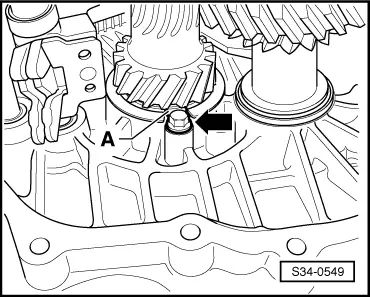

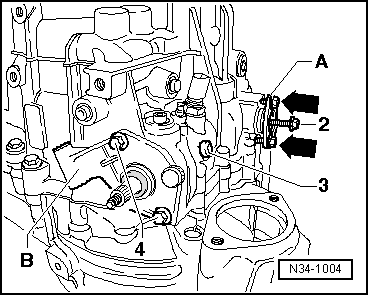

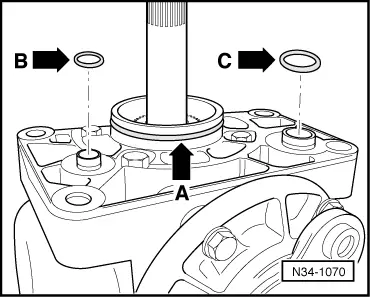

| Always replace the O-ring for sealing the angle gearbox/manual gearbox -arrow A- and the O-rings for sealing the bushings for oil supply -arrow B- and -arrow C- and lightly oil. |

| –

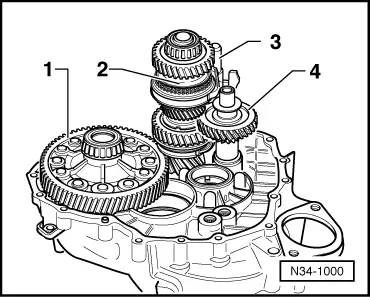

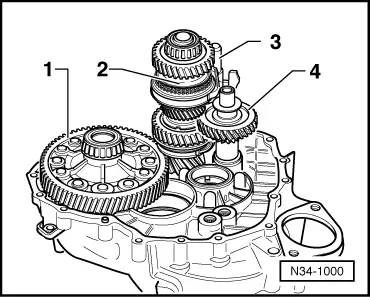

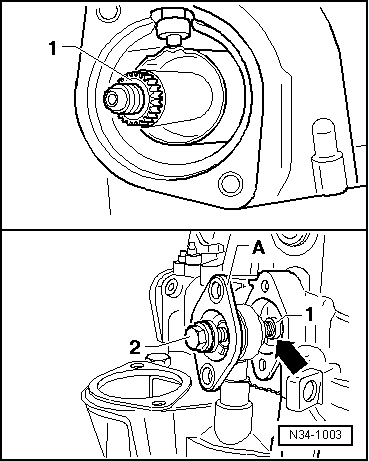

| On the manual gearbox, grease the rigid serration at the differential gear with grease for plug serration of clutch disc -G 000 100-. |

| –

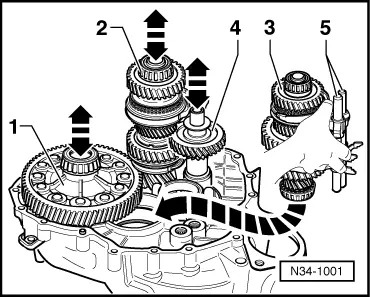

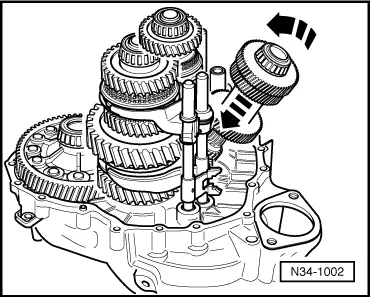

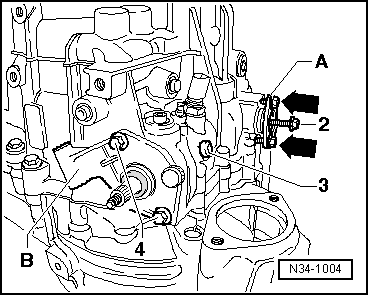

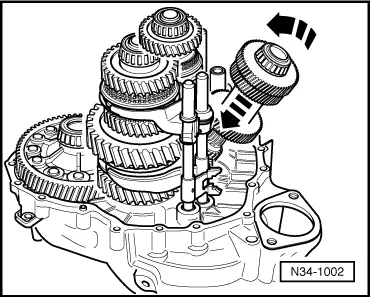

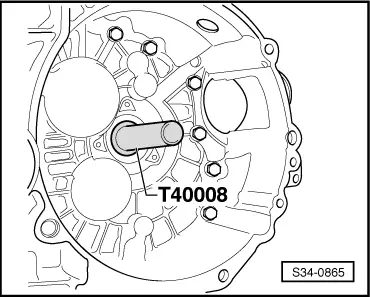

| Push angle gearbox fully onto the manual gearbox, while doing so centrically guide the serration of the drive shaft/angle gearbox together with the coupling sleeve/differential gear. |

| –

| Bring the serration of the right flange shaft and differential bevel gear also into alignment, if necessary turn at the flange shaft. |

| –

| If tooth positioning and centrical guidance are correct, the angle gearbox slips up to the stop against the manual gearbox. |

| –

| Do not pull angle gearbox with the fixing screws against the manual gearbox, otherwise the angle gearbox can tilt and the fixing eyes can break off. |

|

|

|

Note

Note

Note

Note