| t

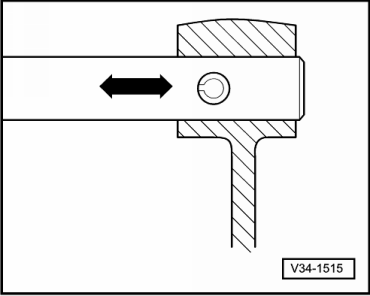

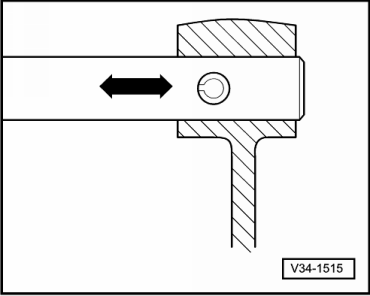

| When installing the manual gearbox, ensure the dowel sleeves are correctly located between the engine and gearbox. |

| t

| When assembling mounts as well as waxed components, the contact surfaces must be cleaned. Contact surfaces must be free of wax and grease. |

| t

| When replacing the manual gearbox or the angle gearbox, the oil level must be checked, if necessary top up gear oil to lower edge of the filler hole → Chapter. |

| t

| When replacing the rear final drive, the oil level must be checked, if necessary top up gear oil and oil for the Haldex coupling to lower edge of the filler hole. |

| t

| Clean contact surfaces thoroughly and apply sealant -AMV 188 200 03-. |

| t

| Apply sealant -AMV 188 200 03- evenly, and not too thickly. |

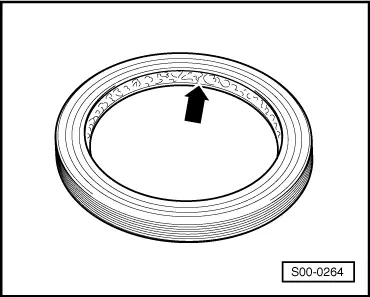

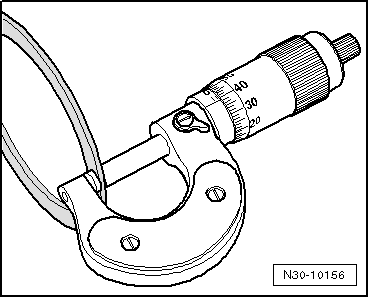

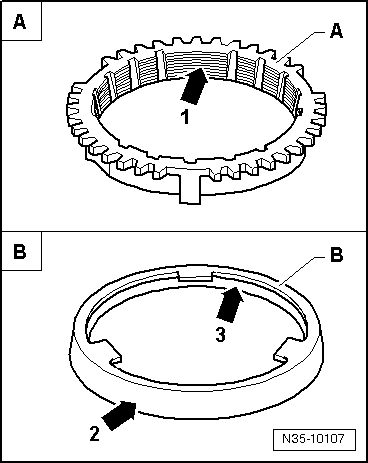

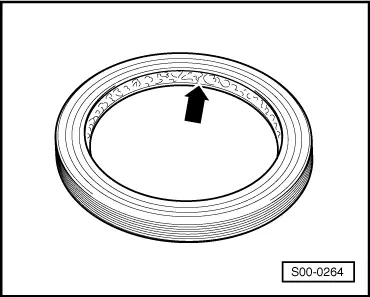

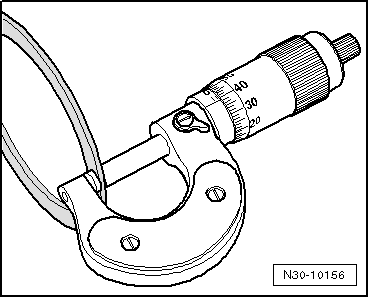

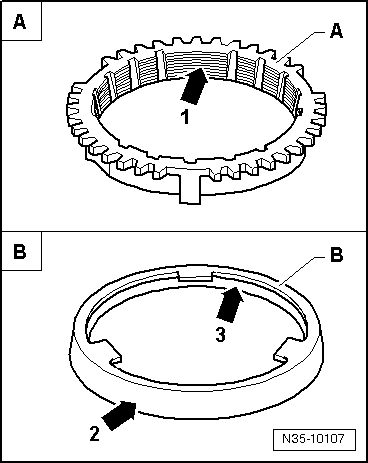

| Gasket rings, O-rings, gaskets |

| t

| After removing the gasket rings, check the contact surface on the housing or on the shaft for burrs or damage which occured during the assembly. |

|

|

|