| Installing - engines with identification characters AVU, BFQ |

Note | t

| Always replace the seals and gaskets during assembly work. |

| t

| Replace the self-locking screws and nuts. |

| t

| Clean all threaded holes into which self-locking bolts are inserted, with a thread tap to remove residues of the locking fluid. |

| t

| Coat stud bolts of exhaust manifold with hot bolt paste -G 052 112 A3- before installing. |

| Installation is performed in the reverse order, pay attention to the following points: |

| –

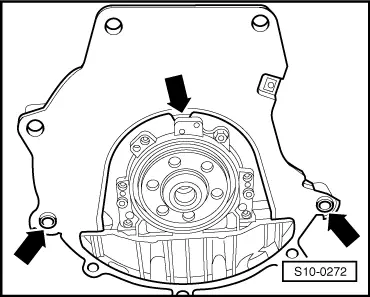

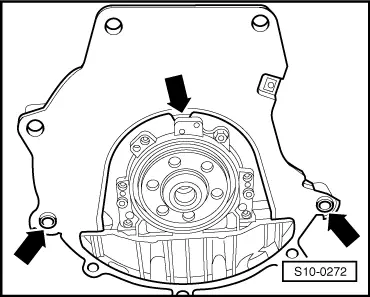

| Check whether the dowel sleeves for centering the gearbox are present in the cylinder block, insert if necessary. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note