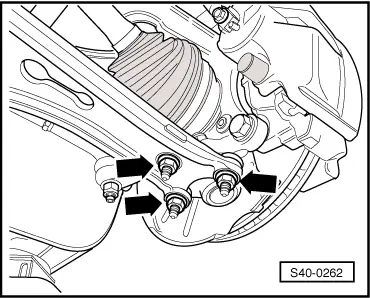

Wheel-bearing housing to suspension strut| t

| the tip of bolt must point in the direction of travel |

| 70 Nm + 90° |

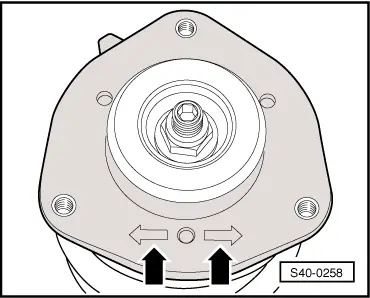

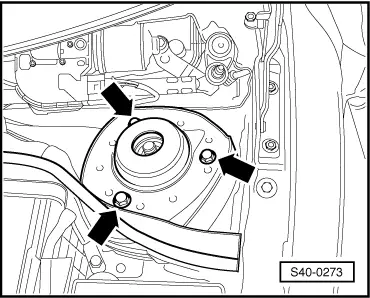

| Suspension strut to body | 15 Nm + 90° |

| Steering joint to track control arm | |

| t

| Track control arm made of steel casting |

| 60 Nm |

| t

| Track control arm made of steel sheet |

| 100 Nm |

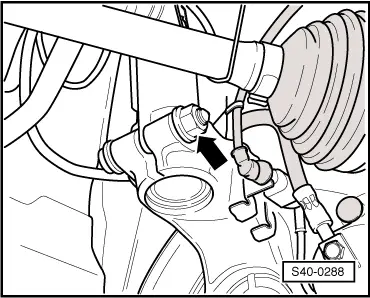

Coupling rod to suspension strut| t

| Counterhold the internal serration of the pivot pin |

| 65 Nm |

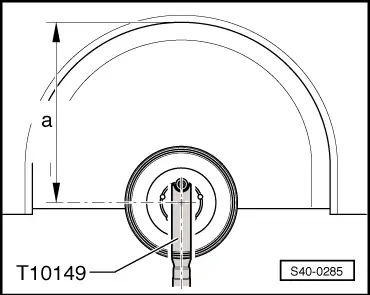

Drive shaft to wheel hub with wheel bearing „hexagon screw“| t

| Vehicle must not be standing on its wheels for tightening the screw |

| 200 Nm + 180° |

Drive shaft to wheel hub with wheel bearing „twelve-sided bolt“| t

| Vehicle must not be standing on its wheels for tightening the screw |

| 70 Nm + 90° |

| Wheel bolts | 120 Nm |

Note

Note Note

Note