| –

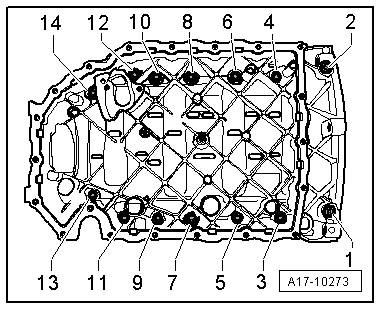

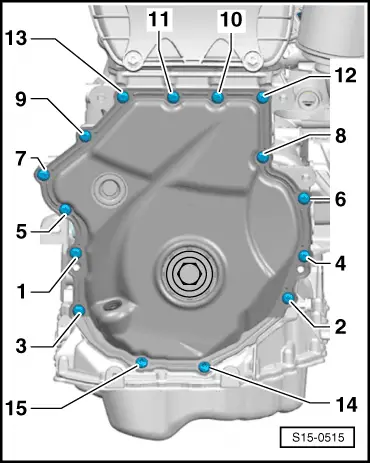

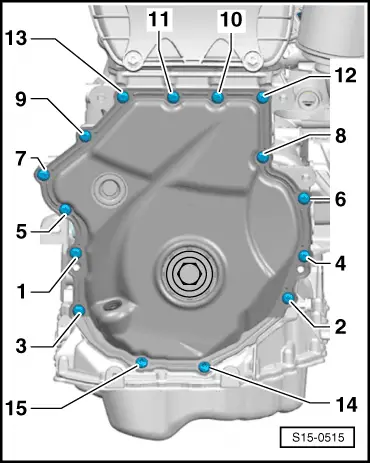

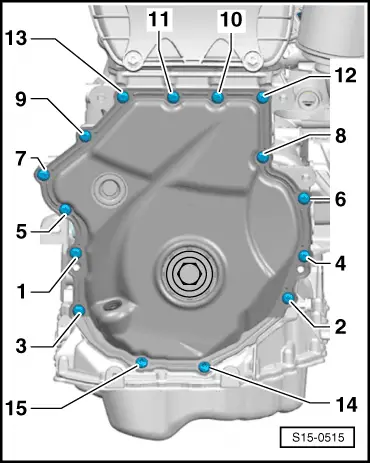

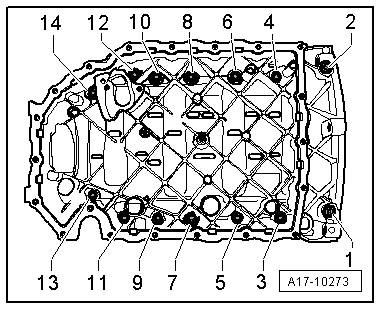

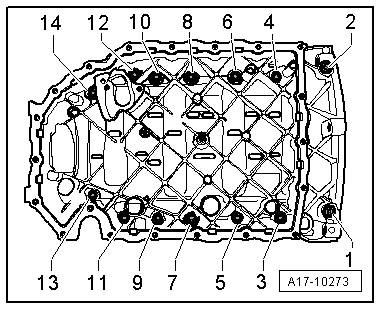

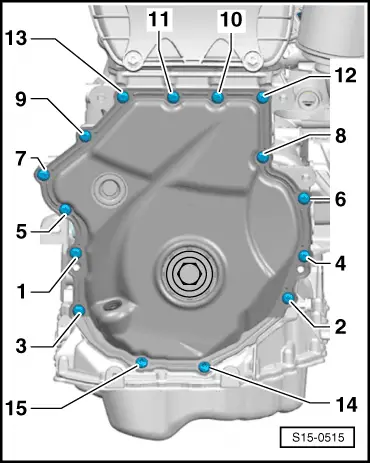

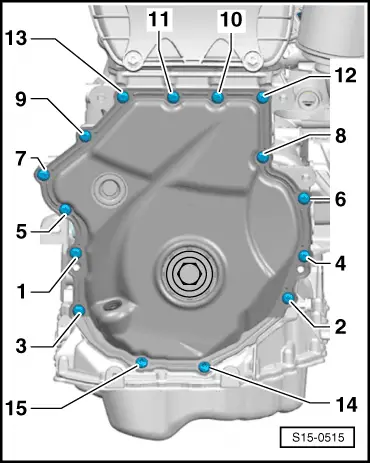

| Release screws -14 and 15- from bottom cover for timing chain. |

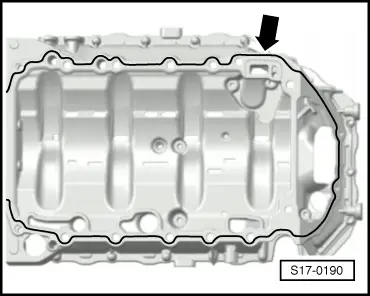

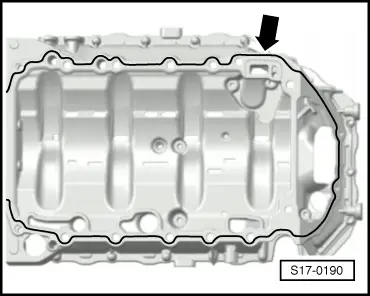

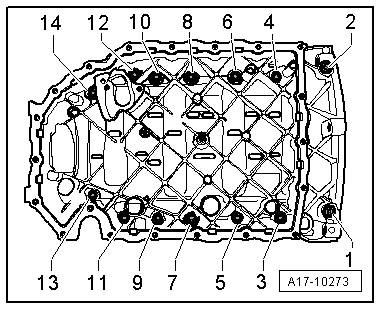

Caution | In order to avoid future leakage, do not deform the bottom cover for the timing chain and do not grip between the screw points when pressing off the oil pan upper part. |

|

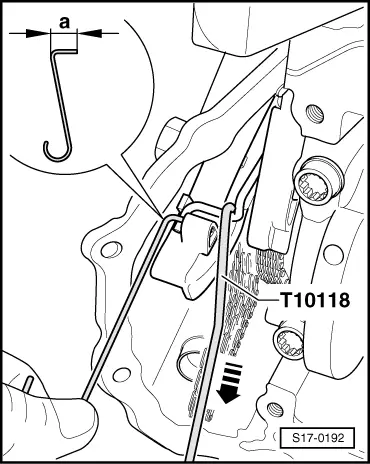

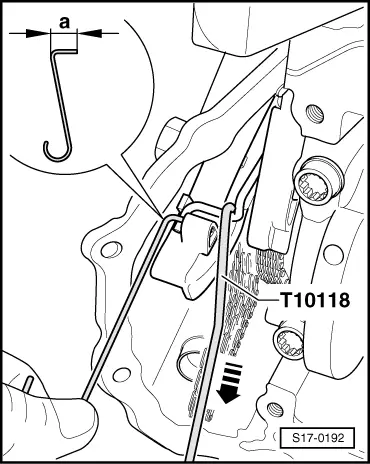

WARNING | Risk of accident! When removing the upper part of the oil pan, the spring of the chain tensioner for the oil pump drive jumps from the upper part of the oil pan to the bottom cover for the timing chain. When removing the upper part of the oil pan, do not grip between the upper part of the oil pan and the bottom cover for the timing chain. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note