Octavia Mk2

| 1 - | 120 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | do not oil |

| q | to release and tighten use counterholder -T30004- or counterholder -MP 1-310 (3099)- |

| 2 - | 20 Nm |

| q | self-locking, replace |

| 3 - | small guide pulley |

| 4 - | 20 Nm + torque a further 45° (1/8 turn) |

| 5 - | Tensioning pulley |

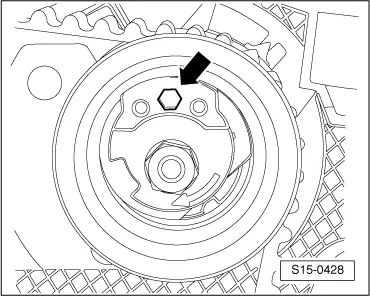

| q | The eccentric of the new version has an additional hole for 6 mm hexagon socket wrench → Fig. |

| 6 - | Toothed belt |

| q | mark the direction of rotation with chalk or a felt-tip pen before removing |

| q | check for wear |

| q | do not kink |

| q | removing → Chapter |

| q | install (set the timing) → Chapter |

| 7 - | 25 Nm |

| 8 - | Toothed belt sprocket of exhaust camshaft |

| q | Check fitting position |

| 9 - | 25 Nm |

| 10 - | Toothed belt sprocket of inlet camshaft |

| q | Check fitting position |

| 11 - | 100 Nm |

| q | to release and tighten use counterholder -T10051- |

| 12 - | 100 Nm |

| q | to release and tighten use counterholder -T10051- → Chapter |

| 13 - | Hub |

| q | for exhaust camshaft |

| q | to remove use extractor -T10052- |

| 14 - | Hub |

| q | for inlet camshaft with rotor for hall sender -G40- |

| q | to remove use extractor -T10052- → Chapter |

| 15 - | Rear toothed belt guard |

| 16 - | Rubber grommet |

| q | for the removal of the hall sender -G40- (rear toothed belt guard must not be removed) |

| q | replace if damaged |

| 17 - | 10 Nm |

| q | insert using locking agent -D 000 600 A2- |

| 18 - | O-ring |

| q | replace |

| 19 - | Coolant pump |

| q | removing and installing → Chapter |

| 20 - | 15 Nm |

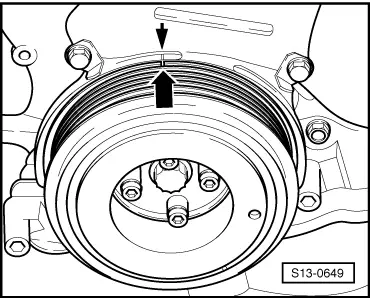

| 21 - | Toothed belt sprocket of crankshaft |

| q | there must not be any oil present on the contact surface between the toothed belt sprocket and the crankshaft |

| q | can be installed only in one position |

| 22 - | large guide pulley |

| 23 - | screw for guide pulley |

| q | replace |

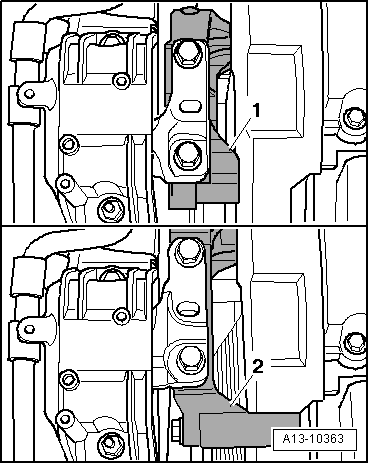

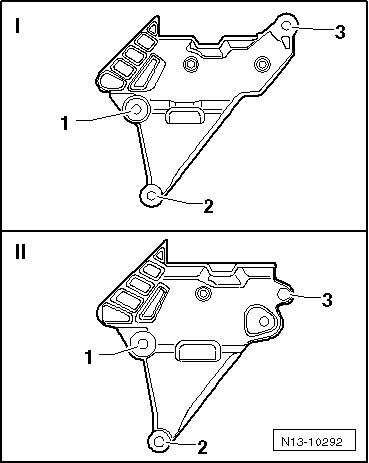

| q | different screws for vehicles with small or large engine support |

| q | Tightening torque: |

| t | Vehicles with small engine support: → Fig. |

| t | Vehicles with large engine support: → Fig. |

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Caution

Caution