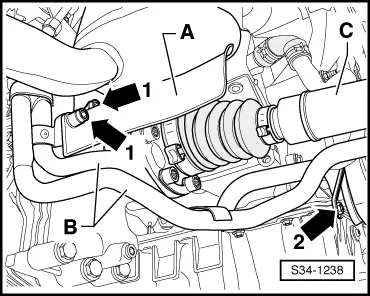

| Vehicles with auxiliary heating. |

| –

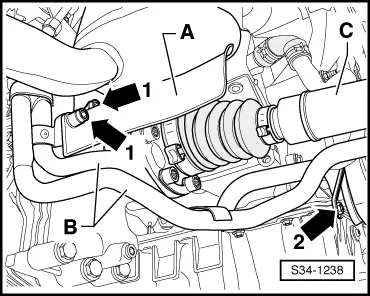

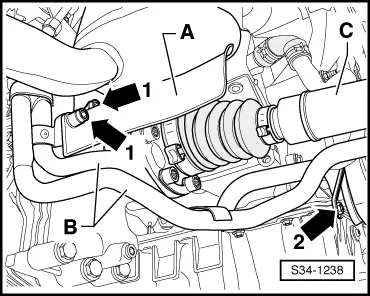

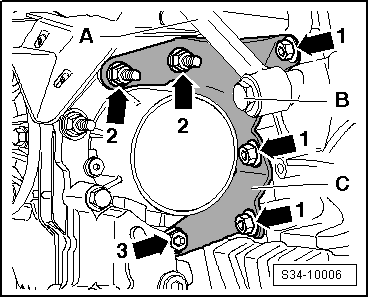

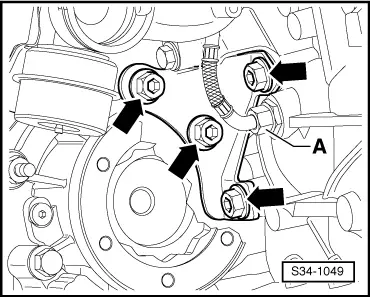

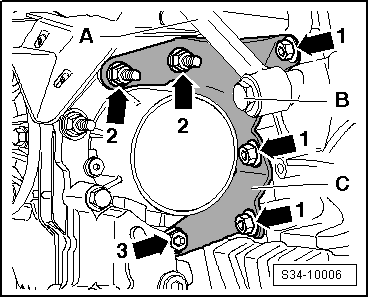

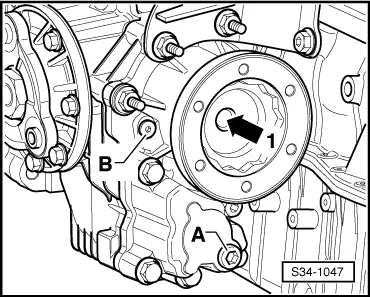

| On these vehicles, fit the coolant pipes -B- onto the double screws at the angle gearbox and install on the engine -arrow 2-. |

| –

| Install heat shield -A- for drive shaft, if present -arrows 1-. |

| –

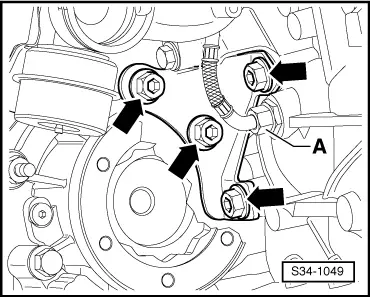

| Install assembly carrier with pendulum support, anti-roll bar, consoles, steering gear and track control arms → Chassis; Rep. gr.40. |

Note | t

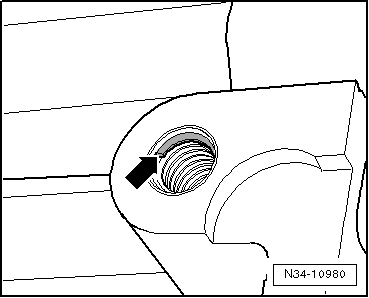

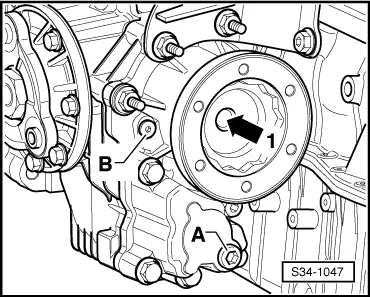

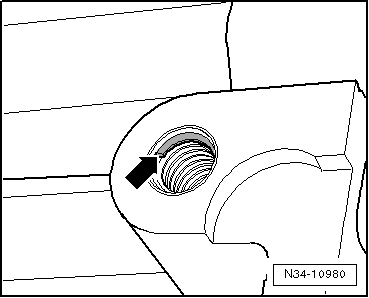

| As of gearbox manufacturing date 28.05. 07, the threaded inserts are located in the bolt-holes for the pendulum support (e.g. „Heli-Coil“). |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note