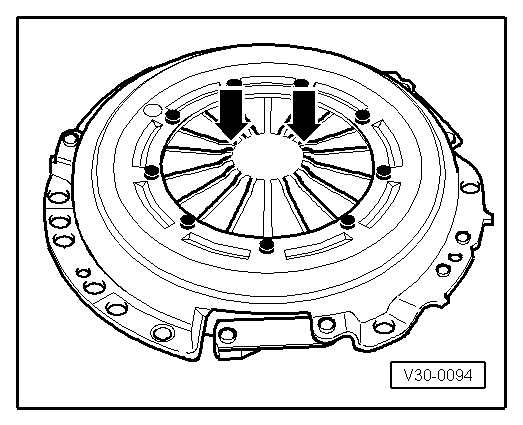

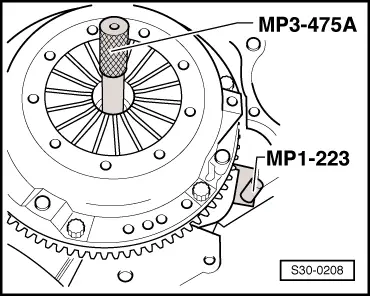

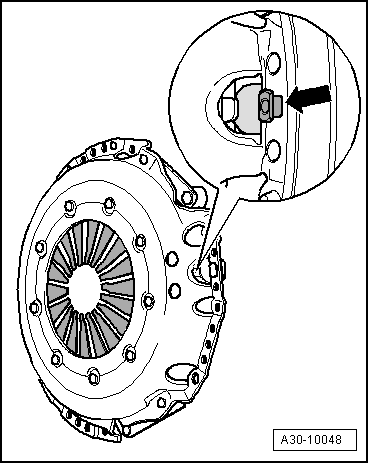

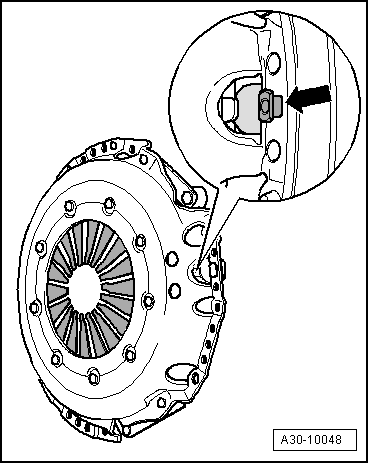

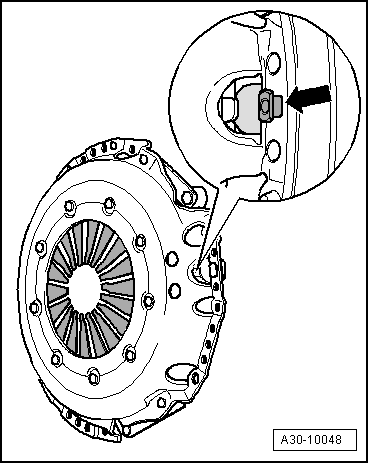

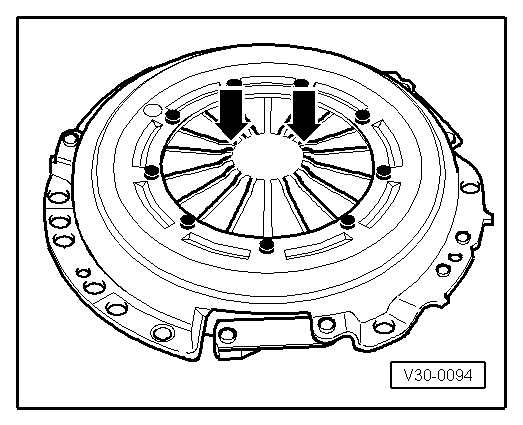

| In order to avoid a deformation of the pressure plate when installing it (this leads to jerking during start-up), the pressure plate must be installed as follows: |

| –

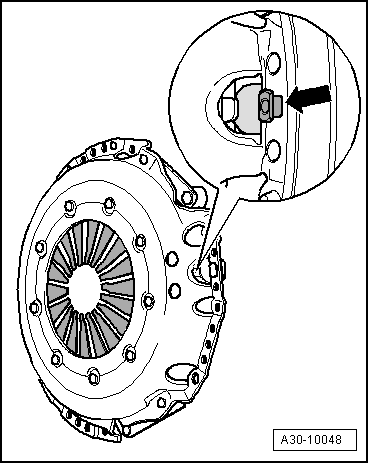

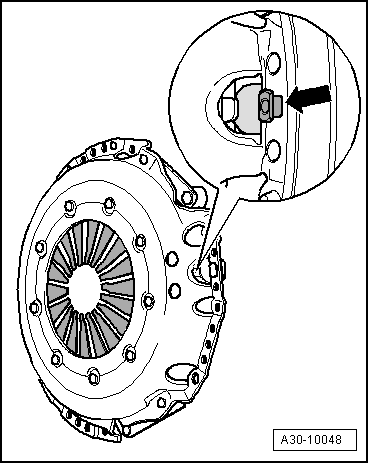

| Pay attention that the stop bolt (position sensor) -arrow- can move freely. |

| –

| Screw in all the screws by hand uniformly, until the bolt head rests against the pressure plate. |

| –

| Tighten the screws gradually and crosswise so as not to damage the centering holes on the pressure plate and the centering pins of the flywheel, while doing so the stop bolt -arrow- must not be lifted up from the pressure plate. |

| –

| Tighten all 6 screws gradually to tightening torque → Item |

|

|

|

Note

Note

Note

Note