Octavia Mk2

| Electric/electronic components and fitting locations (Octavia II, Superb II) |

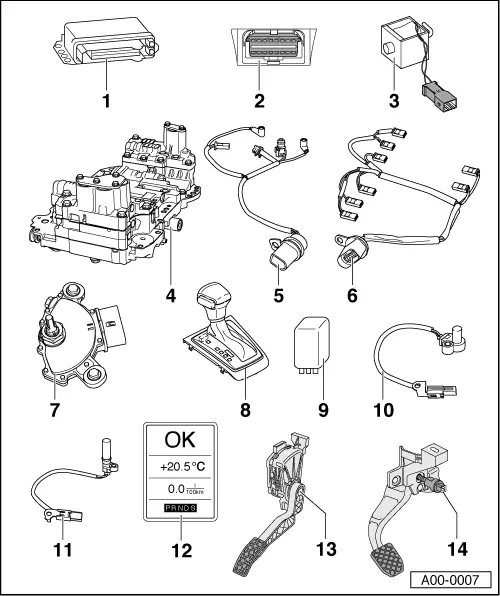

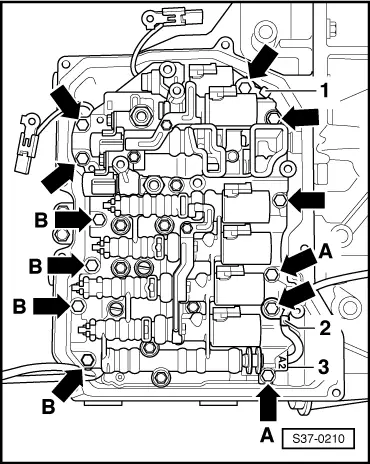

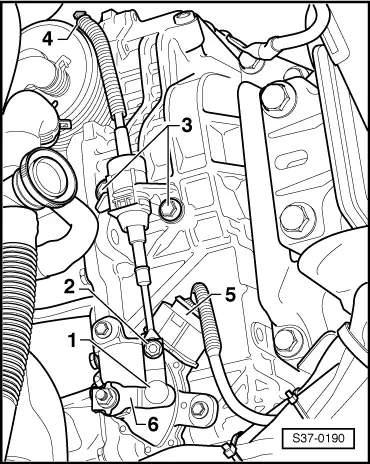

| 1 - | Automatic gearbox control unit -J217- |

| q | Fitting location, removing and installing → Chapter |

| q | Control unit is checked by self-diagnosis |

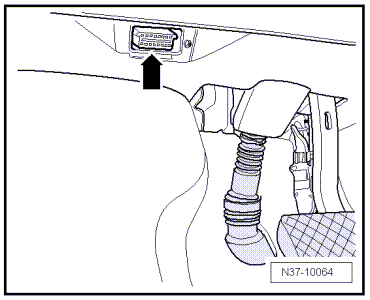

| 2 - | Diagnostic connection |

| q | Fitting location: Cover in driver's footwell → Fig. |

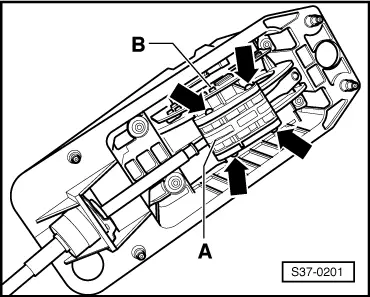

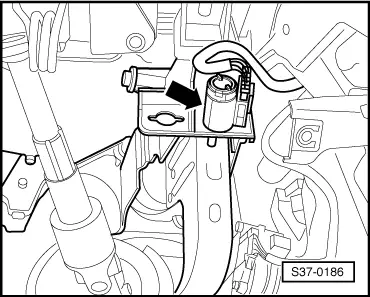

| 3 - | Selector lever lock solenoid -N110- |

| q | Fitting location → Fig. |

| q | is checked by self-diagnosis |

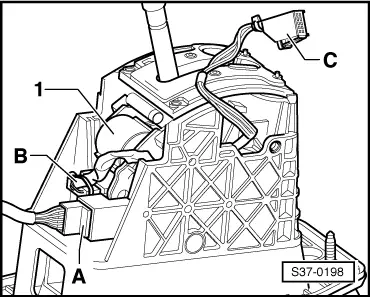

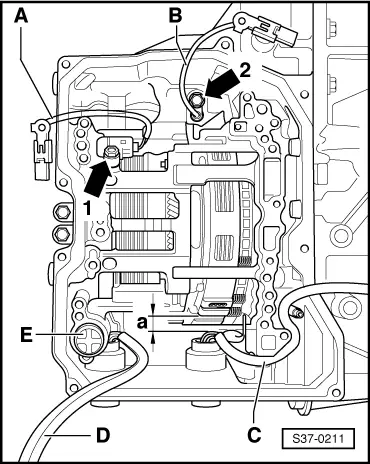

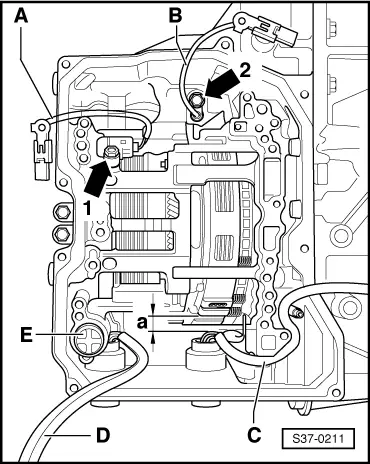

| 4 - | Slide valve body |

| q | Fitting location → Fig. |

| q | removing and installing → Chapter |

| q | Marking of solenoid valves → Chapter |

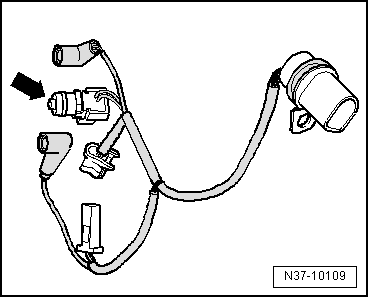

| 5 - | Wiring loom with 8-pin plug and integrated gearbox oil temperature sender -G93- |

| q | Fitting location: Wiring loom is fixed to the slide valve body. → Fig. |

| q | Gearbox oil temperature sender -G93- is checked by self-diagnosis |

| q | removing and installing → Chapter |

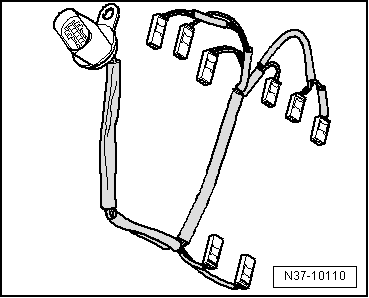

| 6 - | Wiring loom with 14-pin plug |

| q | for solenoid valves and gearbox sensors |

| q | Fitting location: Wiring loom is fixed to the slide valve body. → Fig. |

| q | Designation of solenoid valves and wiring loom routing → Chapter |

| q | removing and installing → Chapter |

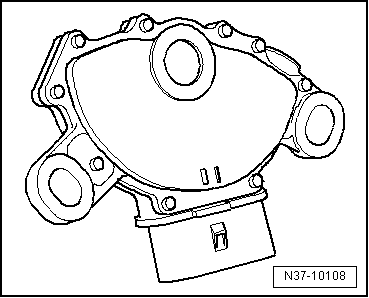

| 7 - | Multi-function switch -F125- |

| q | Fitting location → Fig. |

| q | is checked by self-diagnosis |

| q | removing and installing → Chapter |

| q | adjust → Chapter |

| 8 - | Cover for shift mechanism |

| q | removing and installing → Chapter |

| q | the Tiptronic switch -F189- ist integrated in the shift mechanism; Fitting location → Fig. |

| 9 - | Terminal 50, voltage supply relay -J682- |

| q | up to 05.05 fitting location : E-box in the engine compartment → Current flow diagrams, Electrical fault finding and Fitting locations |

| q | as of 06.05 fitting location: additional relay holder under the dash panel → Current flow diagrams, Electrical fault finding and Fitting locations |

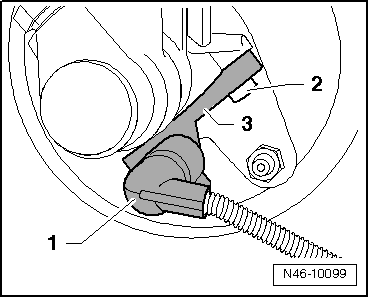

| 10 - | Gearbox input r.p.m. sender -G182- |

| q | Fitting location → Fig. |

| q | is checked by self-diagnosis |

| q | removing and installing → Chapter |

| 11 - | Gearbox output r.p.m. sender -G195- |

| q | Fitting location → Fig. |

| q | is checked by self-diagnosis |

| q | removing and installing → Chapter |

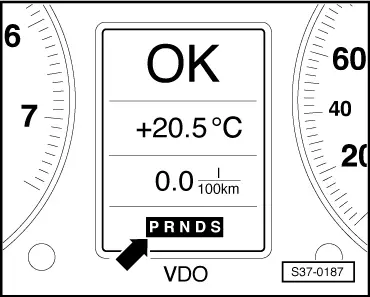

| 12 - | Selector lever position indicator -Y6- |

| q | Fitting location → Fig. |

| q | a switched off gear display points to an emergency operation with deactivated gearbox control unit |

| q | a fully lit gear display points to an emergency operation with activated gearbox control unit |

| q | removing and installing → Electrical System; Rep. gr.90 |

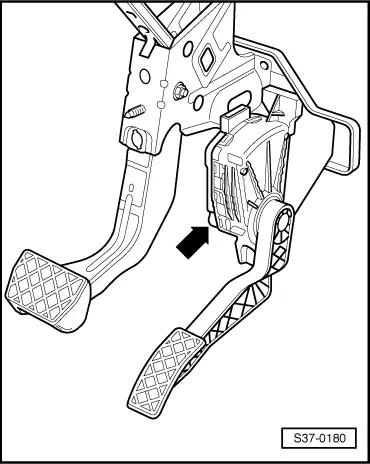

| 13 - | Kick-down switch -F8- |

| q | Fitting location → Fig. |

| q | is checked by self-diagnosis |

| q | Signal transfer from engine to gearbox control unit via CAN databus |

| q | removing and installing accelerator pedal module → Engine; Rep. gr.20 |

| 14 - | Brake light switch -F- |

| q | Fitting location up to 05.10 → Fig. |

| q | Fitting location as of 06.10 → Fig. |

| q | Signal transfer from engine to gearbox control unit via CAN databus |

| q | is checked by self-diagnosis |

| q | removing and installing → Chassis; Rep. gr.46 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|