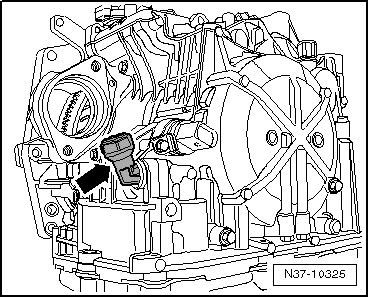

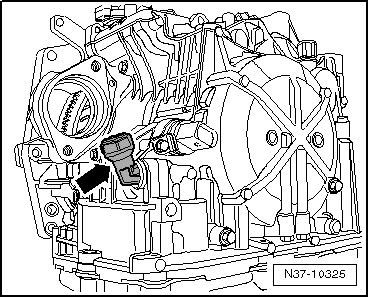

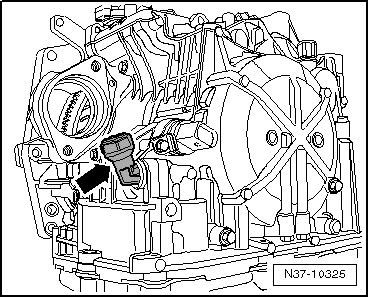

| The ATF filler tube is no longer available on gearboxes as of production date 06.06 -arrow-. |

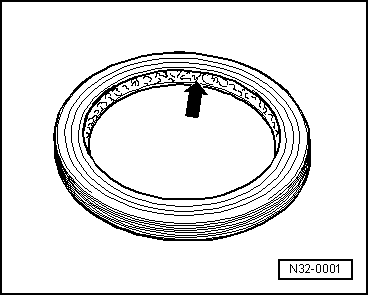

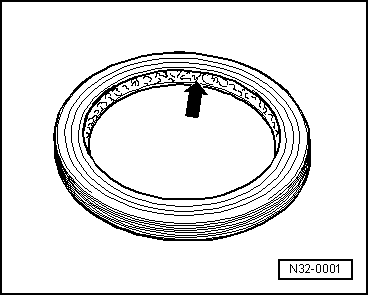

| O-rings, gasket rings, gaskets |

| t

| Always replace O-rings, gaskets and gasket rings. |

| t

| After removing gaskets, examine the contact surface in the housing or on shafts for burrs or damage, and correct if necessary. |

| t

| Depending on location, before fitting a gasket ring, smear the outer surface and sealing lip thinly with ATF or axle oil. |

| t

| Before inserting the O-rings coat with ATF to prevent the rings being squashed during installation. |

| t

| The open side of the sealing rings is turned towards the oil. |

| t

| Never use other lubricants in the ATF area. |

|

|

|