| Removing and installing oil pan |

| Special tools and workshop equipment required |

| t

| Plug in unit -T10058- or -3249- |

| t

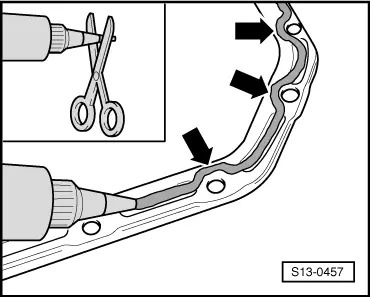

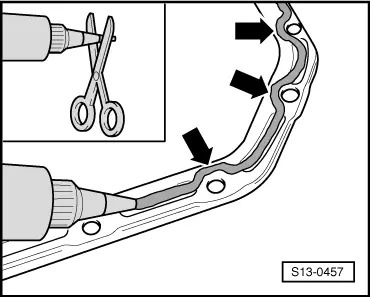

| Sealant remover gasket stripper (bearing code GST, bearing article no. R 34402), manufacturer Retech s.r.o. |

| t

| Cleaning agent and grease remover e.g. -D 009 401 04- |

| t

| Silicone sealant -D 176 600 A1- |

| –

| Remove the noise insulation. |

| –

| Unscrew pre-exhaust pipe from exhaust manifold → Chapter. |

| –

| Disconnect plug from oil level and oil temperature sender -G266-. |

| –

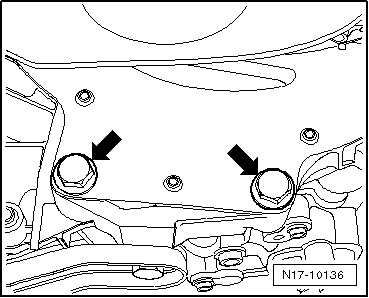

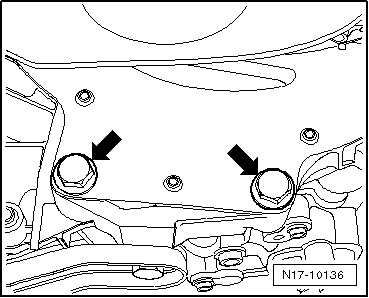

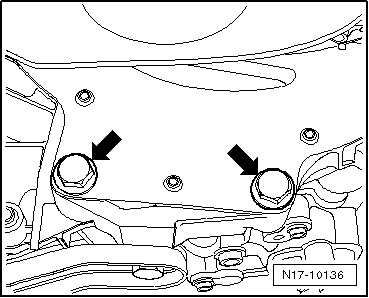

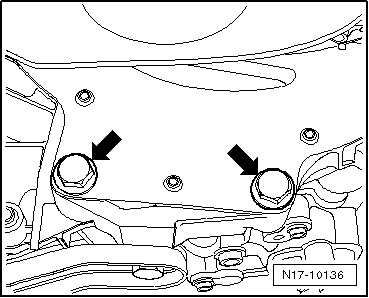

| Release two fixing screws from the gearbox flange and the oil pan. |

| For engines with identification characters BUD, CGGA |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note