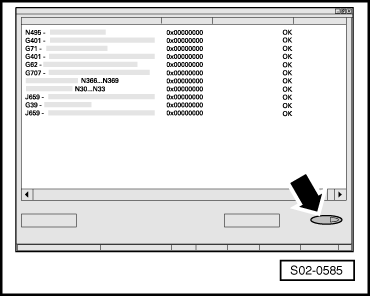

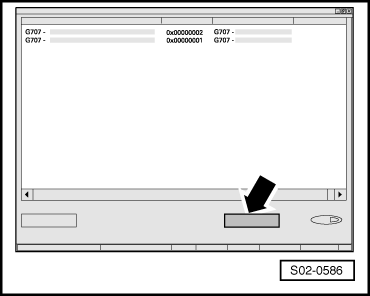

| Connecting the diagnostic unit, interrogating and erasing the fault memory of the liquefied petroleum gas control unit (LPG) |

| For vehicles manufactured up to 12.2010 (exhaust emission standard EU-4) |

| Special tools and workshop equipment required |

| t

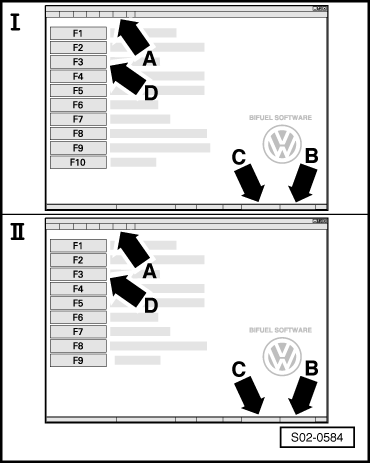

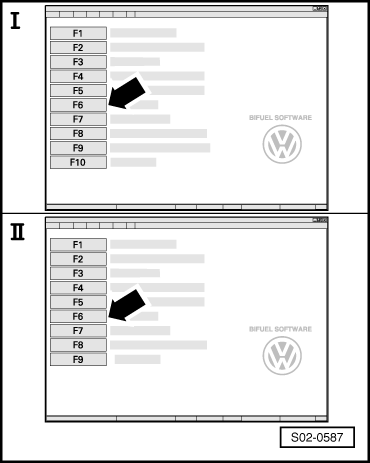

| Diagnostic software on CD - Bi-fuel -JNV 910 787- |

| t

| Diagnostic cable for liquefied petroleum gas control unit LPG -JNV 971 603 - |

| t

| Vehicle diagnosis, measurement and information system -VAS 505X- or a notebook |

Caution | The liquefied petroleum gas control unit LPG can be damaged when improperly using different functions of the diagnostic program as described below. |

|

Note | t

| The diagnostic software on CD -JNV 910 787- must subsequently be installed in -VAS 505X-, if necessary in a commercially available notebook. |

| t

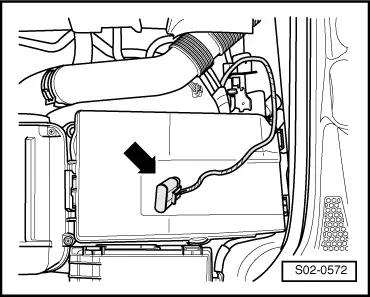

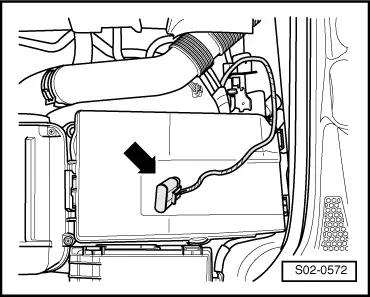

| The diagnostic connector for the liquefied petroleum gas control unit is located in the engine compartment, namely in the area of the battery, behind which the liquefied petroleum gas control unit (LPG) can also be found. |

| t

| In order to reach the diagnostic connector and the liquefied petroleum gas control unit (LPG), the battery cover must be removed. After the diagnosis is performed, place the connector again in the area of the battery. |

| t

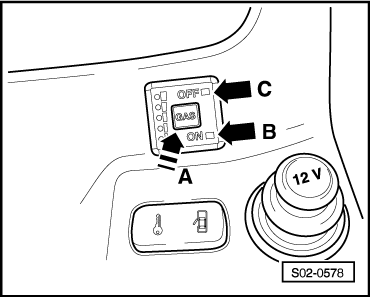

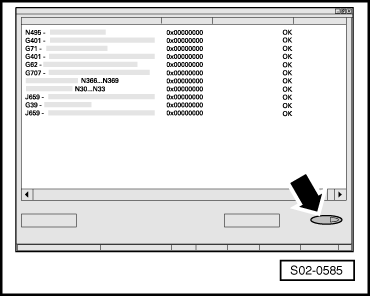

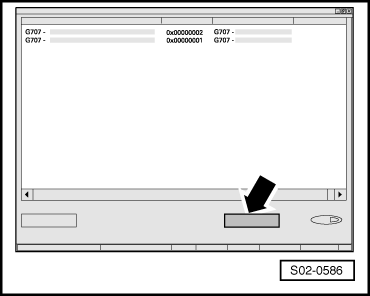

| The fault memory of the liquefied petroleum gas control unit (LPG) can only be interrogated while the engine is running. When the ignition is switched on (engine stoppage), a connection with the liquefied petroleum gas control unit (LPG) cannot be established. |

|

|

|

Note

Note

Note

Note