Octavia Mk2

|

| 1 - | 15 Nm |

| 2 - | Drive chain sprocket |

| q | at the crankshaft |

| q | removing and installing → Chapter |

| 3 - | Dipstick |

| q | Oil level must not exceed the max. marking |

| 4 - | Filler funnel |

| q | The filler funnel and the guide pipe are one component part |

| q | Tightening torque → Fig. |

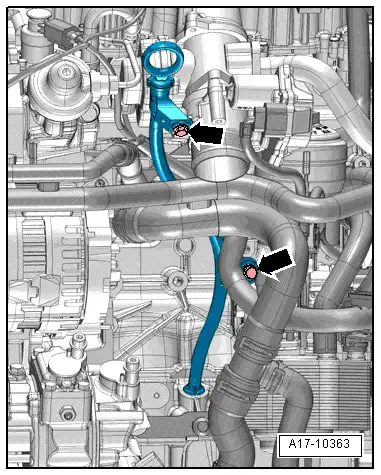

| 5 - | Guide tube |

| q | The filler funnel and the guide pipe are one component part |

| q | Tightening torque → Fig. |

| 6 - | Oil injection nozzle |

| q | for piston cooling |

| q | removing and installing → Fig. |

| 7 - | Pressure valve, 27 Nm |

| q | opens at a pressure of 0.25 ... 0.32 MPa (2.5 ... 3.2 bar) |

| q | replace without sealant |

| q | removing and installing → Fig. |

| 8 - | O-ring |

| q | replace |

| 9 - | Intake manifold |

| q | Clean strainer if dirty |

| 10 - | Baffle |

| 11 - | Right charge air pipe |

| q | on the inlet side → Chapter |

| 12 - | 8 Nm |

| 13 - | Oil pan |

| q | removing and installing → Chapter |

| q | install with silicone sealant -D 176 404 A2- |

| 14 - | Drain plug, 30 Nm |

| q | with integrated gasket ring |

| q | replace |

| 15 - | 10 Nm |

| q | replace |

| 16 - | Oil level and oil temperature sender -G266- |

| q | check → Vehicle diagnostic tester |

| q | removing and installing → Chapter |

| 17 - | O-ring |

| q | replace |

| 18 - | Oil pump |

| q | with safety valve 1,2 MPa (12 bar) |

| q | removing and installing → Chapter |

| q | before installing, check whether both dowel sleeves are present |

| q | if there is any scoring on the contact surfaces of the gears, replace |

| q | Tighening torque of oil pump cover at oil pump housing: 10 Nm |

| 19 - | Oil pump sprocket |

| q | Fits onto oil pump shaft in one position only |

| 20 - | Right charge air pipe |

| q | on the outlet side → Chapter |

| 21 - | 25 Nm |

| 22 - | Oil pump chain |

| q | before removing mark running direction |

| q | check for wear |

| 23 - | Chain tensioner |

| q | do not disassemble |

| q | Replace chain tensioner if spring is broken |

| q | Check fitting position |

| q | When installing, hook on the spring and pretension |

| q | tighten to 16 Nm |

| 24 - | Sealing flange on the belt pulley side |

| q | must be positioned on dowel sleeves |

| q | removing and installing → Chapter |

| q | Replace crankshaft seal on belt pulley side → Chapter |

|

|