| –

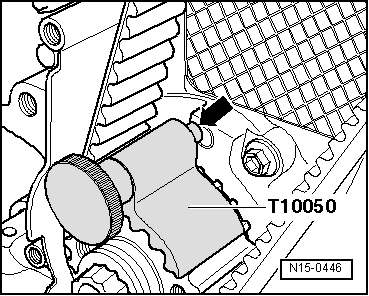

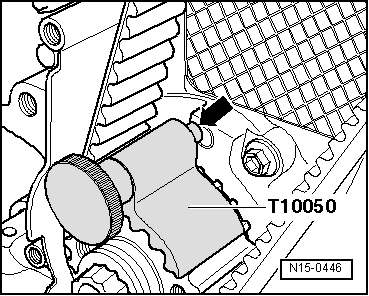

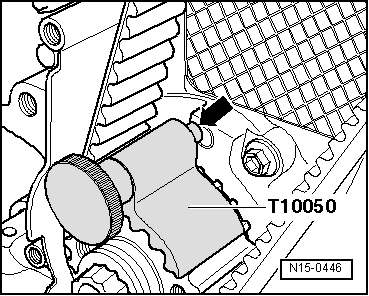

| Rotate the crankshaft in direction of rotation of engine on TDC and lock the crankshaft with the crankshaft arrester -T10050-. |

Note | If the cylinder head was replaced, refill the entire system with coolant. |

| –

| Filling and bleeding the fuel system. For this purpose, connect the vehicle diagnosis, measurement and information system -VAS 505X- and carry out the targeted function „bleeding the fuel system“. During this function, the fuel pump is actuated for 180 seconds. |

Note | After deleting the fault memory of the engine control unit the readiness code must be checked, if necessary re-generated → Vehicle diagnostic tester. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note