Octavia Mk2

| Timing belt drive - Summary of components |

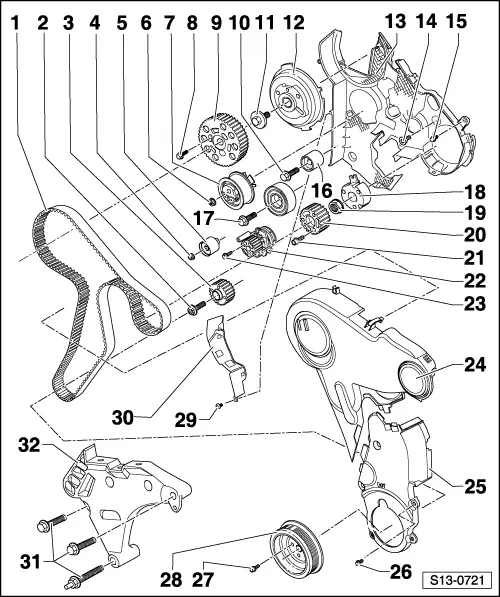

| 1 - | Toothed belt |

| q | before removing mark running direction |

| q | check for wear |

| q | do not kink |

| q | removing and installing → Chapter |

Note

Note| If the toothed belt is replaced when carrying out engine repair (apart from regular change interval), it should be entered in the → Service Schedule! |

| 2 - | 120 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | to release and tighten use counterholder -T30004 (3415)- |

| q | Neither oil nor grease thread or collar. |

| q | tightening may occur in successive stages |

| 3 - | Crankshaft - toothed belt sprocket |

| q | at the crankshaft |

| 4 - | 20 Nm |

| 5 - | Guide pulley |

| q | for toothed belt |

| 6 - | 20 Nm + torque a further 45° (1/8 turn) |

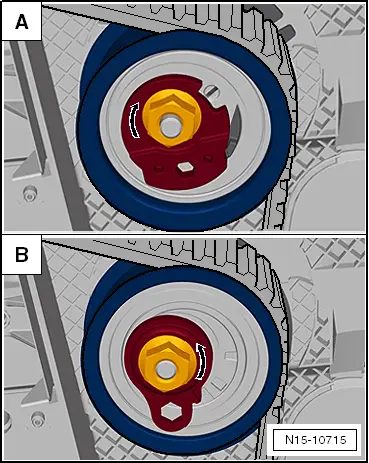

| 7 - | Tensioning pulley |

| q | for toothed belt |

| q | Pay attention to version → Fig. |

| q | for removing and installing, remove engine support → Fig. |

| 8 - | 20 Nm + torque a further 45° (1/8 turn) |

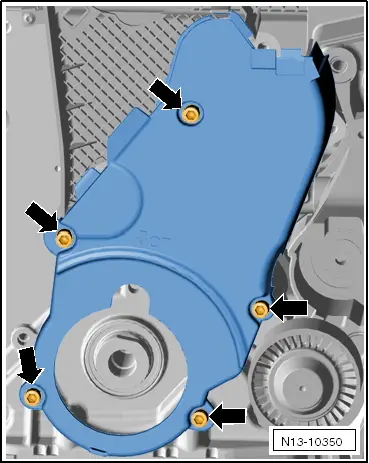

| 9 - | Toothed belt gear |

| q | on the camshaft |

| 10 - | 20 Nm |

| 11 - | 100 Nm |

| q | to release and tighten use counterholder -T10051- |

| 12 - | Hub |

| q | for camshaft |

| q | to remove use extractor -T10052- |

| q | removing and installing → Chapter |

| 13 - | Rear toothed belt guard |

| 14 - | Screws |

| q | Attach high pressure pump |

| q | replace |

| q | tighten: |

| t | M8 x 28: 20 Nm + torque a further 45° (1/8 turn) |

| t | M8 x 90: 20 Nm + torque a further 180° (1/2 turn) |

| 15 - | 9 Nm |

| q | replace |

| 16 - | Guide pulley |

| q | for toothed belt |

| 17 - | 50 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 18 - | Hub |

| q | for high pressure pump |

| q | to release and tighten use counterholder -T10051- |

| q | to remove use extractor -T40064- |

| q | removing and installing → Chapter |

| 19 - | 95 Nm |

| 20 - | Toothed belt gear |

| q | on the high pressure pump |

| 21 - | 20 Nm |

| 22 - | Coolant pump |

| q | removing and installing → Chapter |

| 23 - | 15 Nm |

| 24 - | Timing belt guard - top part |

| q | Assignment → Electronic Catalogue of Original Parts |

| 25 - | Timing belt guard - bottom part |

| q | removing and installing → Fig. |

| q | Assignment → Electronic Catalogue of Original Parts |

| 26 - | 9 Nm |

| q | apply locking agent -D 000 600 A2- before installing |

| 27 - | 10 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 28 - | Crankshaft-belt pulley |

| q | with vibration damper |

| 29 - | 5 Nm |

| 30 - | Protection plate |

| 31 - | 40 Nm + torque a further 180° (1/2 turn) |

| q | replace |

| q | observe the order of tightening up → Fig. |

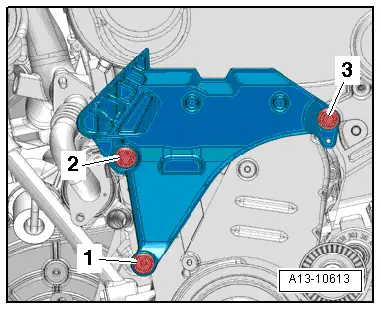

| 32 - | Engine support bracket |

| q | removing and installing → Fig. |

Note

Note

|

|

| Stage | Tightening order | Torque/torquing angle |

| 1. | -2, 1, 3-, | 7 Nm |

| 2. | -2, 1, 3- | 40 Nm |

| 3. | -2, 1, 3- | 180° (1/2 turn) |

|

|