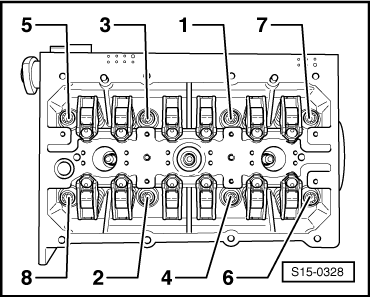

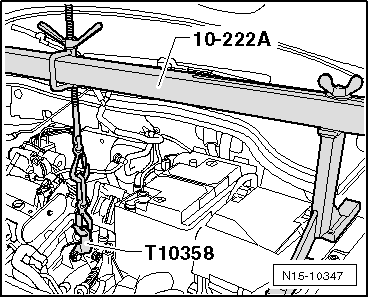

| For engines with identification characters BZG, CGPA, CGPB, CEVA, CJLA, BME |

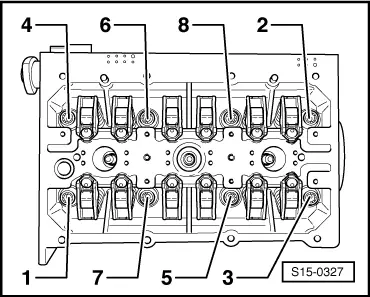

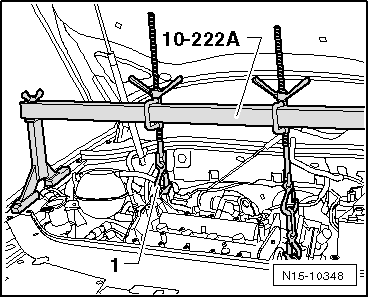

| Continued for all engines |

| –

| Carefully remove the cylinder head. |

Note | Do not lay the cylinder head on the surface with the head combustion chamber - danger of damaging the spark plugs. |

| l

| The pistons must not be positioned at top dead centre. |

WARNING | Wear protective gloves and goggles when working with gasket remover and degreasing agent! |

|

| Remove gasket residues on cyliner head with sealant remover. |

Note | t

| Always replace the cylinder head bolts. |

| t

| There must not be any oil or coolant present in the threaded holes for the cylinder head bolts. |

| t

| Remove the new cylinder head gasket from its wrapping immediately before fitting. |

| t

| Treat the new seal with the utmost care. Any damage will result in leaks. |

| –

| Check whether both sleeves which are intended for the guide of the cylinder head, are inserted into the cylinder block above; insert if necessary. |

| –

| Position the new cylinder heads. The legend (part number) must be legible. |

| –

| Insert the cylinder head. |

| –

| Insert new cylinder head screws into the screw contact surface lightly oiled and tighten by hand. |

| –

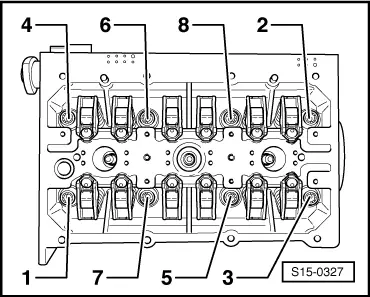

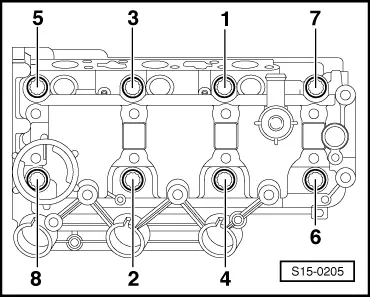

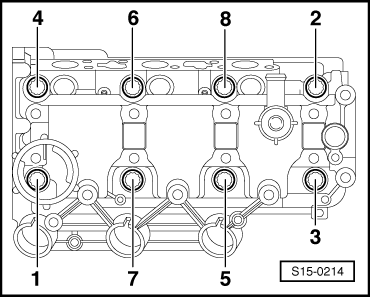

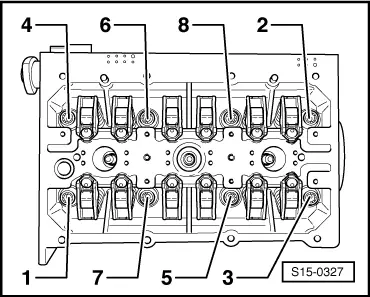

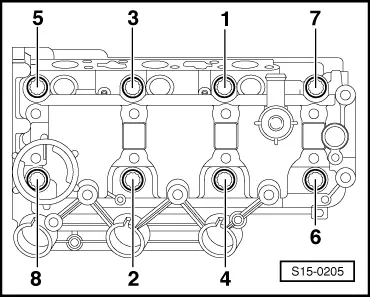

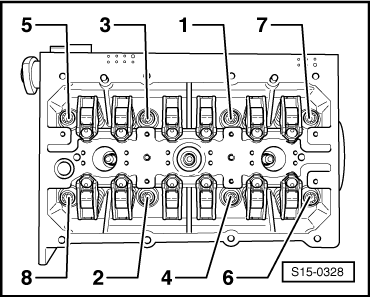

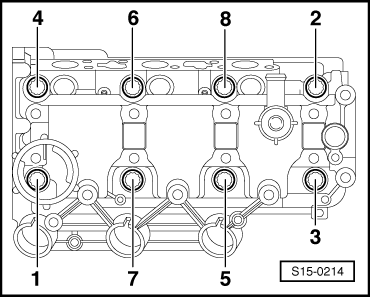

| Tighten cylinder head in three stages in the following order: |

|

|

|

Note

Note Note

Note

Note

Note Note

Note