Roomster

|

|

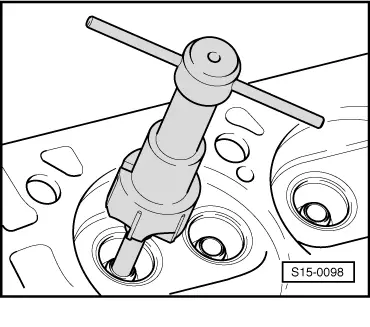

| Valve guide | Ø Guide drift in mm |

| Inlet valve | 6,0 -0,01 |

| Exhaust valve |

|

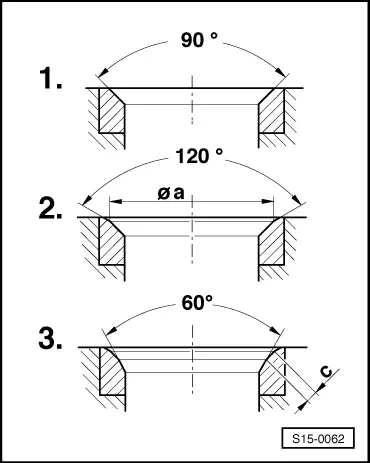

| Valve seat | Ø Milling cutter 90° mm | Ø Milling cutter 120° mm | Ø Milling cutter 60° mm | |

| Inlet valve | Engine BBM, CHFA | 36 | 38 | 21/34 |

| BME, BZG, CGPA, CGPB, CEVA, CJLA engine | 32 | 32 | 21/34 | |

| Exhaust valve | Engine BBM, CHFA | 30 | 30 | 21/34 |

| BME, BZG, CGPA, CGPB, CEVA, CJLA engine | 30 | 30 | 21/34 | |

|

|

Note

Note

|

|