| –

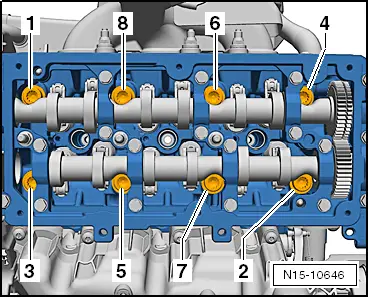

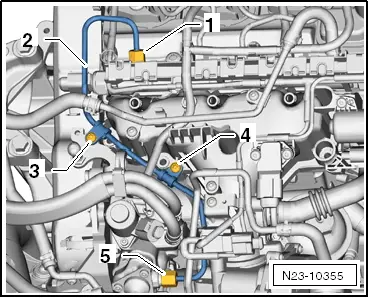

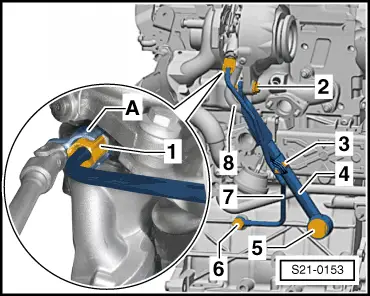

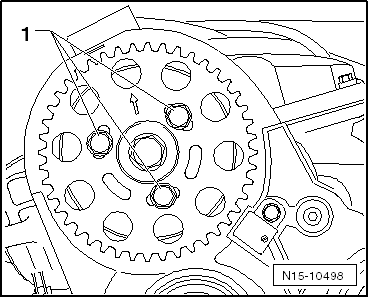

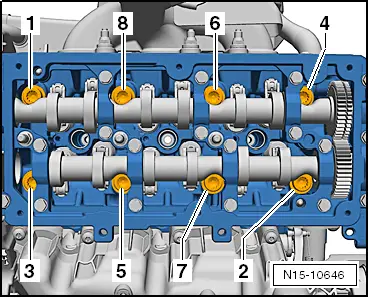

| Follow the sequence -1 … 8- for loosening the cylinder head screws. |

| –

| Release cylinder head screws. |

Note | t

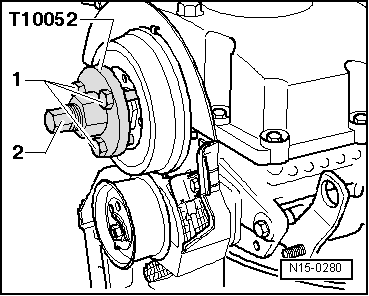

| The assistance of a second mechanic is required for removing the cylinder head. |

| t

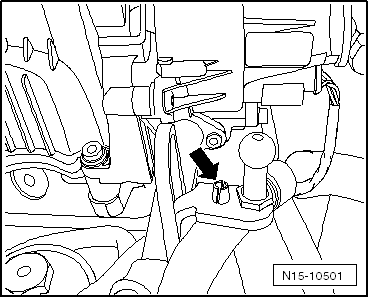

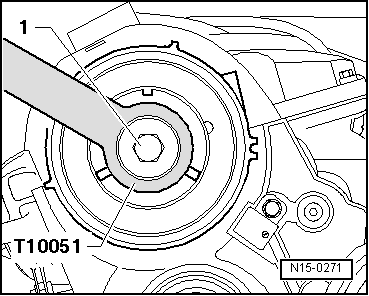

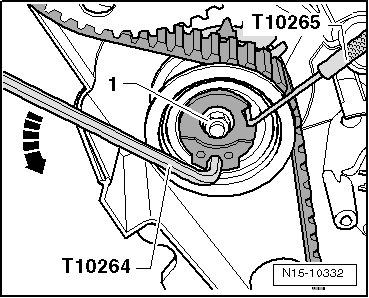

| The timing belt tensioning pulley is removed from the pin screw when lifting out the cylinder head. |

| –

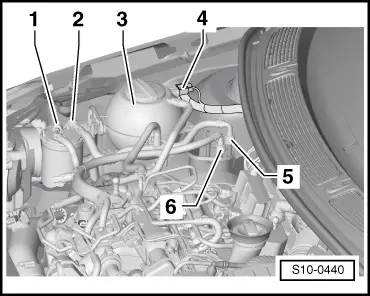

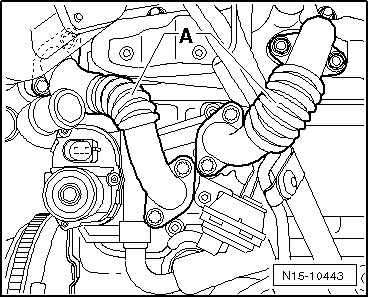

| First of all raise the cylinder head on the gearbox side and thread it out of the rear toothed belt guard. Make sure that the timing belt tensioning pulley does not fall down. |

Caution | Risk of damage to the glow plugs when placing down the cylinder head. |

| If the cylinder head is removed with installed glow plugs, do not place it down on the sealing surface since the glow plugs protrude slightly beyond the sealing surface. |

|

| –

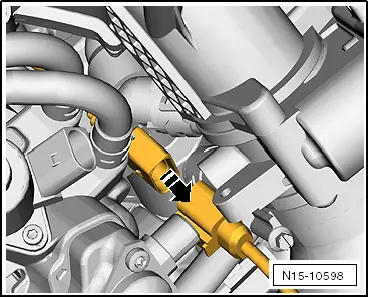

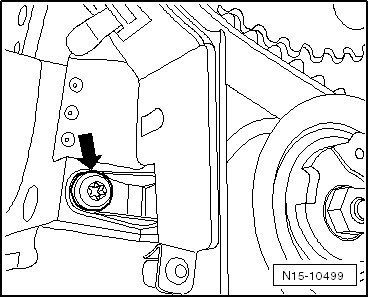

| Place down the cylinder head in such a way that the oil return flow line does not bend, if necessary place a wooden wedge under the exhaust manifold. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution