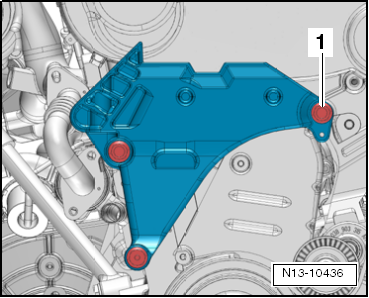

| –

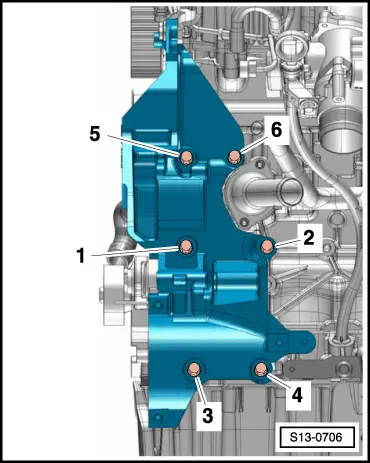

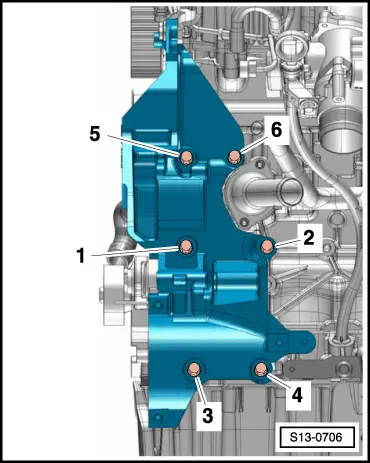

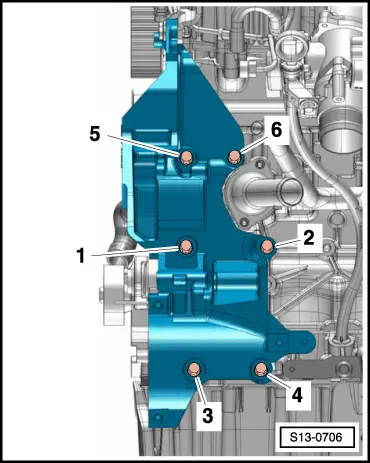

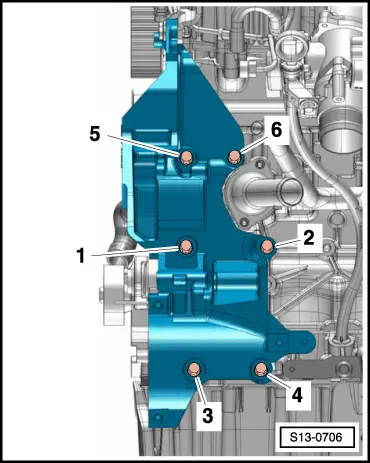

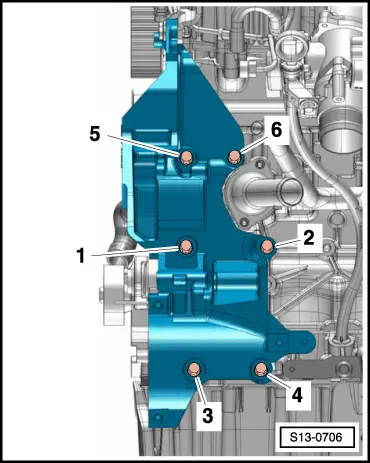

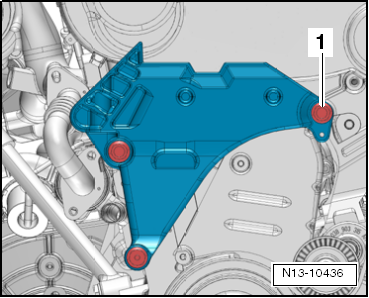

| Release screws in the sequence -6 … 1- and remove bracket for auxiliary units. |

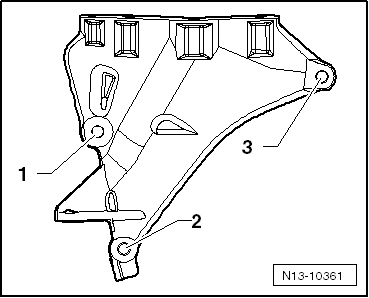

| Installation is performed in the reverse order, pay attention to the following points: |

Note | t

| A dowel sleeve must be located between the bracket for auxiliary units and the cylinder block in the screw hole -6-. |

| t

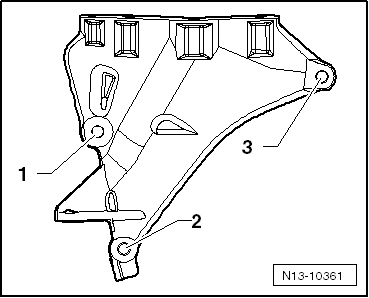

| Replace all the screws of the bracket for auxiliary units and the engine support, which have been tightened to a torquing angle. |

| t

| Before tightening the fixing screws of the bracket for auxiliary units, screw in the screw of the engine support by hand. |

|

|

|

Note

Note

Note

Note