Roomster

| 1 - | 20 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | pay attention to sequence for loosening and tightening → Chapter |

| 2 - | Valve-lever shaft |

| q | do not interchange |

| 3 - | Cylinder head bolt |

| q | replace |

| q | pay attention to sequence for loosening and tightening → Chapter |

| q | before fitting insert washers (Pos. 4) in the cylinder head |

| 4 - | Washer |

| q | for cylinder head screws |

| q | insert in cylinder block before fitting the bearing cap |

| 5 - | Bucket tappets |

| q | do not interchange |

| q | with hydraulic valve clearance compensation |

| q | lay aside with contact surface facing down |

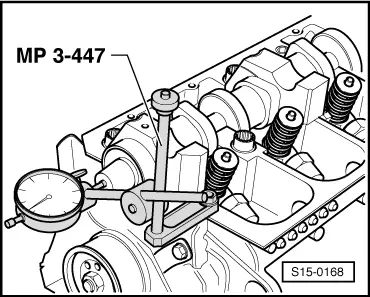

| q | before installing check axial play of the camshaft → Fig. |

| q | oil contact surfaces |

| q | before removing remove the camshaft bearing shells |

| 6 - | Valve collets |

| 7 - | Valve spring retainer |

| 8 - | Valve spring outside |

| q | removing and installing: |

| t | Cylinder head removed: with -MP 1-206 (3047 A)-, -MP 1-211 (VW 541/1a,/5)-, -MP 1-213 (2036/1)- |

| t | Cylinder head fitted → Chapter |

| 9 - | Valve spring inside |

| q | removing and installing: |

| t | Cylinder head removed: with -MP 1-206 (3047 A)-, -MP 1-211 (VW 541/1a,/5)-, -MP 1-213 (2036/1)- |

| t | Cylinder head fitted → Chapter |

| 10 - | Valve stem seal |

| q | replace → Chapter |

| 11 - | Valve guide |

| q | check → Chapter |

| 12 - | The unit injector |

| q | removing and installing → Chapter |

| 13 - | Cylinder head |

| q | pay attention to note → Chapter |

| q | reworking valve seats → Chapter |

| 14 - | Sealing ring |

| q | Neither oil nor grease sealing lip of sealing ring |

| q | before installing, remove with a clean cloth oil residues from camshaft studs |

| q | before fitting, cover slot on the camshaft cone with adhesive tape (e.g. Scotch tape) |

| q | removing and installing → Chapter |

| 15 - | Valves |

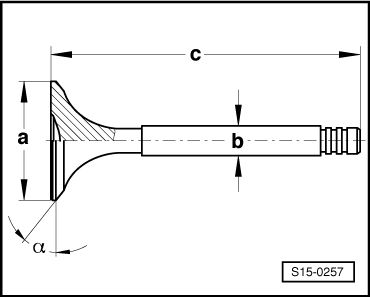

| q | Valve dimensions → Fig. |

| 16 - | Bearing shell |

| q | do not mix up used bearing shells (mark) |

| q | ensure the retaining lugs are correctly located in the bearing caps and in the cylinder head |

| 17 - | Camshaft |

| q | Inspecting axial play → Fig. |

| q | removing and installing → Chapter |

| q | Slack: max. 0.01 mm |

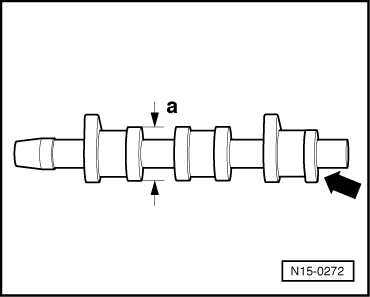

| q | Identification, timing → Fig. |

| 18 - | Bearing caps |

| q | Mounting sequence → Chapter |

| q | Bearing cap 4 is identified like bearing cap 5. |

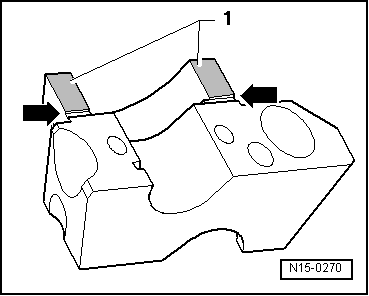

| q | for installing seal the separator surfaces of bearing caps 1 and 4 with sealant -AMV 174 004 01- → Fig. |

| 19 - | 8 Nm + torque a further 90° (1/4 turn) |

| q | replace |

|

|

Note

Note

|

|

Note

Note

|

|

| Dimension | Inlet valve | Exhaust valve | |

| Ø a | mm | 35,95 | 31,45 |

| Ø b | mm | 6,980 | 6,956 |

| c | mm | 89,95 | 89,95 |

| α | ∠° | 45 | 45 |

|

|

| 3. Cylinder -arrow- | 858 C |