| –

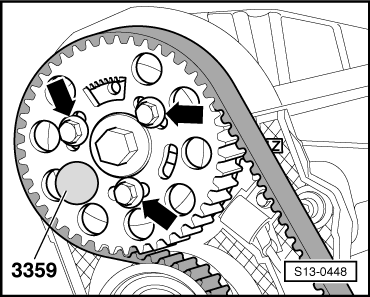

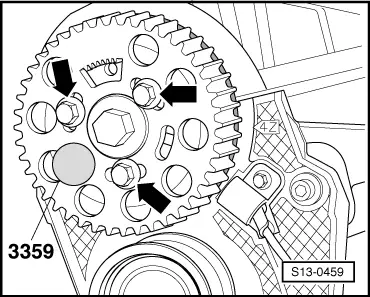

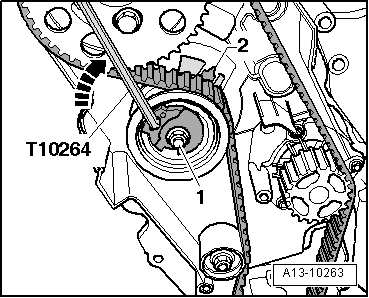

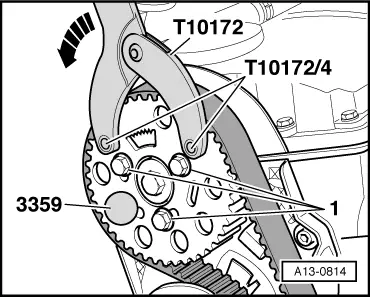

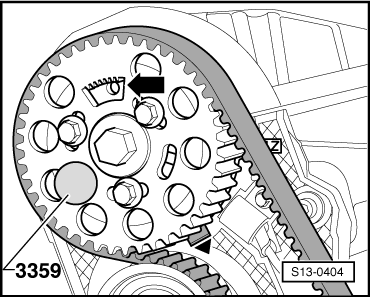

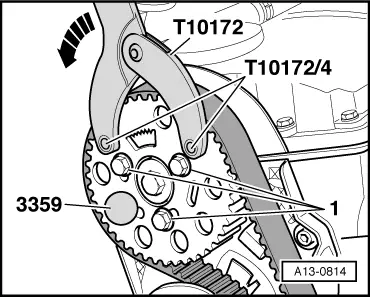

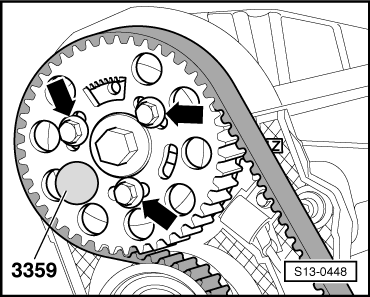

| Torque the fixing screws -arrows- of the camshaft sprocket a further 45° (1/8 turn) using a rigid wrench. While doing so, counterhold the belt pulley with the counterholder -T10172- with adapters -T10172/4-. |

| The further assembly is carried out in the reverse order, while paying attention to the following: |

| –

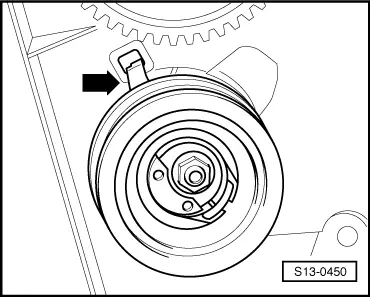

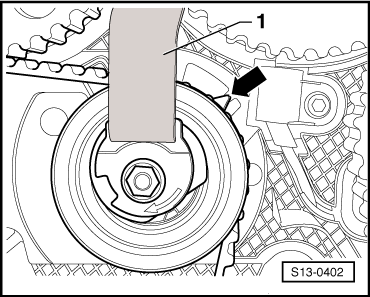

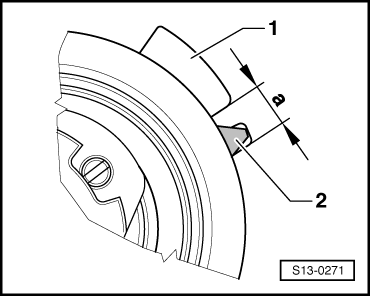

| Install the bottom timing belt guard and the belt pulley/vibration damper. |

| –

| Install middle timing belt guard. |

| –

| Screw tensioning pulley lever of V-ribbed belt on compact holder. |

| –

| Install the fan wheel on the visco fan coupling → Chapter. |

| –

| Install top toothed belt guard. |

| –

| Inspect headlight beam setting and adjust if necessary → Superb. |

WARNING | When undertaking all assembly work, particularly in the engine compartment due to its cramped construction, please observe the following: |

| t

| Lay lines of all kinds (e.g. for fuel, hydraulic fluid, cooling fluid and refrigerant, brake fluid, vacuum) and electrical lines in such a way that the original line guide is re-established. |

| t

| Ensure that there is adequate free access to all moving or hot components. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING