| –

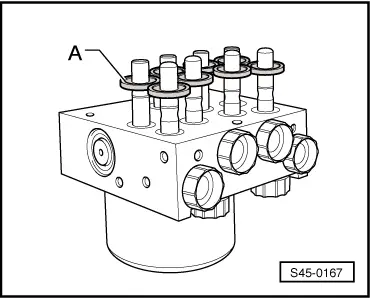

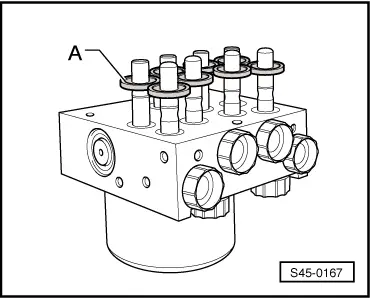

| Push all the gasket rings -A- a little over the valve domes. |

| –

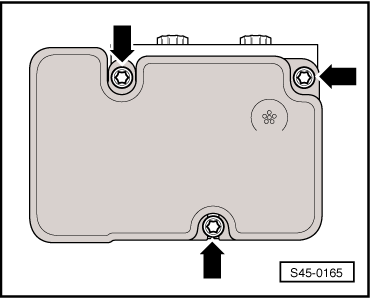

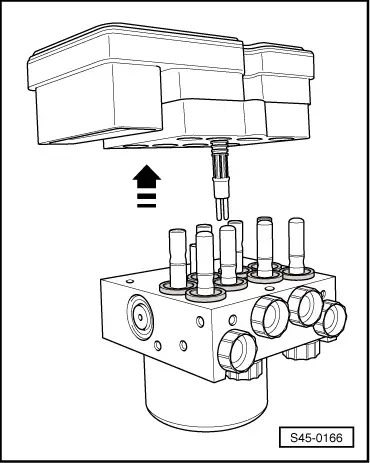

| Position the control unit without tilting it onto the hydraulic unit. |

| Thus the gasket rings are brought into their end position. |

| –

| Screw hydraulic unit and control unit with the enclosed new Torx screws. |

Note | t

| A new control unit may only be installed maximum twice onto the remaining hydraulic unit, in order to ensure tightness of the elastic seal. |

| t

| A control unit, which was once operational, must not be mounted a second time. |

Note | t

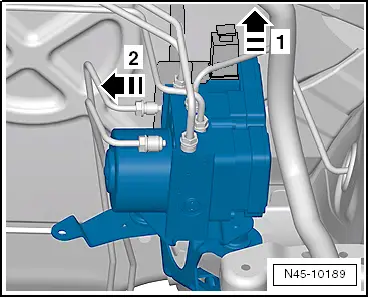

| Only then remove plugs from the new hydraulic unit when the relevant brake line is installed. |

| t

| If the plugs were already removed from the hydraulic unit before the brake line is installed, then brake fluid may escape and adequate filling and bleeding can no longer be guaranteed. |

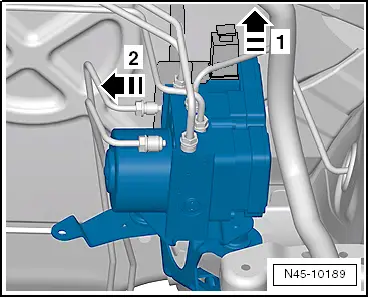

| –

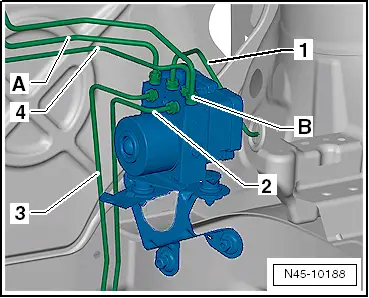

| Screw the bracket onto the hydraulic unit and tighten to the recommended tightening torque. |

| –

| Moisten the bolt of the support → Item with lubricant, e.g. -D 007 000 A2-, before inserting into the rubber bearings. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING