Drive shaft for Yeti power transmission gearbox 02Q

Note

Note| Insert all bearings on the drive shaft with gear oil. |

| For vehicles Octavia II |

| 1 - | Circlip |

| q | removing and installing → Chapter |

| 2 - | Washer |

| q | Outer diameter = 78.6 mm |

| q | can only be used on modified gearbox housings (as of production date 04.06 up to 01.08) → Chapter |

| q | assign components via → Electronic Catalogue of Original Parts |

| 3 - | Gearbox housing |

| q | adapted for the washers Pos. 2 and Pos. 4 as of production date 04 06 up to production date 01.08 in the area of the bearing pedestal for the grooved ball bearing Pos. 6 → Chapter |

| q | flattened parts at the grooved ball bearing and at the bearing pedestal of the grooved ball bearing as of production date 02.08 → Chapter |

| q | assign components via → Electronic Catalogue of Original Parts |

| 4 - | Washer |

| q | Outer diameter = 85 mm |

| q | can only be used on modified gearbox housings (as of production date 04.06 up to 01.08) → Chapter |

| q | assign components via → Electronic Catalogue of Original Parts |

| 5 - | Circlip |

| q | determine → Fig. when replacing the grooved ball bearing -Pos. 6- and the drive shaft -Pos. 8- |

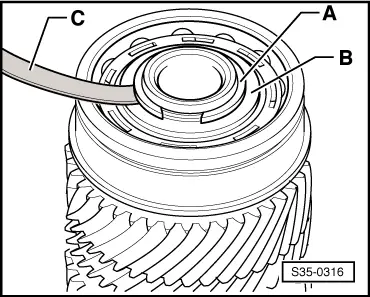

| 6 - | Grooved ball bearing |

| q | always replace → Electronic Catalogue of Original Parts |

| q | flattened parts at the grooved ball bearing and at the bearing pedestal of the grooved ball bearing as of production date 02.08 → Chapter |

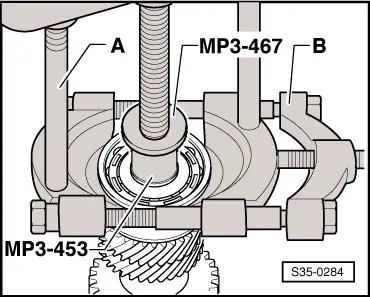

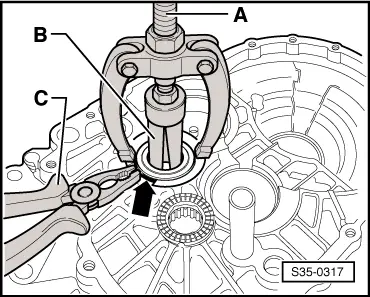

| q | remove → Fig. |

| q | pressing on → Fig. |

| 7 - | 5th gear pinion |

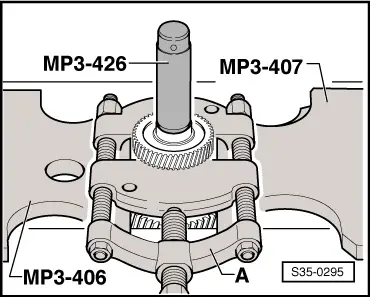

| q | pressing off → Fig. |

| q | Fitting position: round groove -arrow- points to the grooved ball bearing Pos. 6 |

| q | pressing on → Fig. |

| 8 - | Drive shaft |

| q | with 3rd/4th gear pinon and 6th gear |

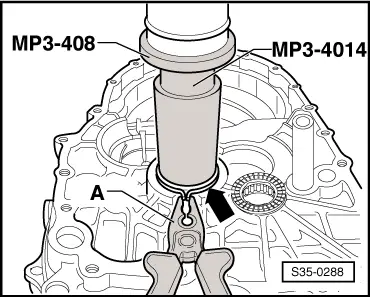

| 9 - | Cylindrical-roller bearing |

| q | with circlip |

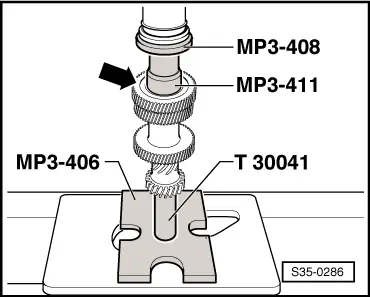

| q | removing → Fig. |

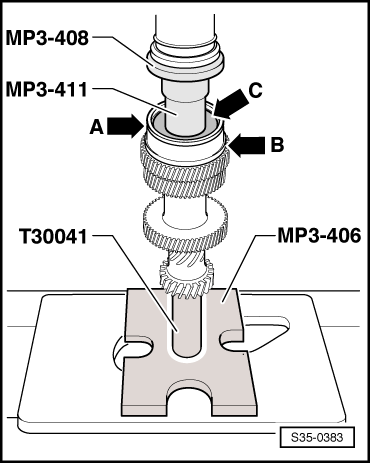

| q | installing → Fig. |

| q | Fitting position: the circlip in the bearing points towards the drive shaft |

| 10 - | Clutch housing |

|

| 1 - | Circlip |

| q | removing and installing → Chapter |

| 2 - | Gearbox housing |

| 3 - | Circlip |

| q | determine → Fig. when replacing the grooved ball bearing -Pos. 4- and the drive shaft -Pos. 6- |

| 4 - | Grooved ball bearing |

| q | always replace → Electronic Catalogue of Original Parts |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 5 - | 5th gear pinion |

| q | remove → Fig. |

| q | Fitting position: round groove -arrow- points to the grooved ball bearing Pos. 4 |

| q | pressing on → Fig. |

| 6 - | Drive shaft |

| q | with 3rd/4th gear pinon and 6th gear |

| 7 - | Cylindrical-roller bearing |

| q | with circlip |

| q | removing → Fig. |

| q | pressing on → Fig. |

| q | Fitting position: the circlip in the bearing points towards the drive shaft |

| 8 - | Clutch housing |

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

| Measured value (mm) | Circlip thickness (mm) | Axial play (mm) |

| 0,01 … 0,05 | 1,86 | 0,01 … 0,05 |

| 0,05 … 0,07 | 1,89 | 0,01 … 0,05 |

| 0,07 … 0,10 | 1,92 | 0,01 … 0,05 |

| 0,10 … 0,13 | 1,95 | 0,01 … 0,05 |

| 0,13 … 0,16 | 1,98 | 0,01 … 0,05 |

|

|

|

|