| t

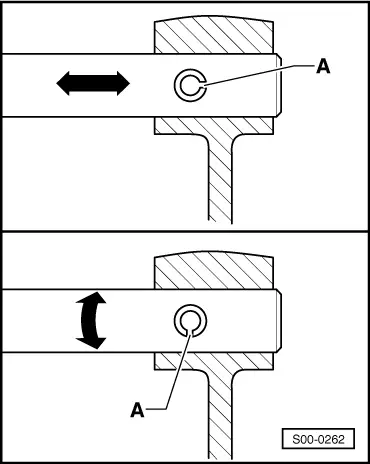

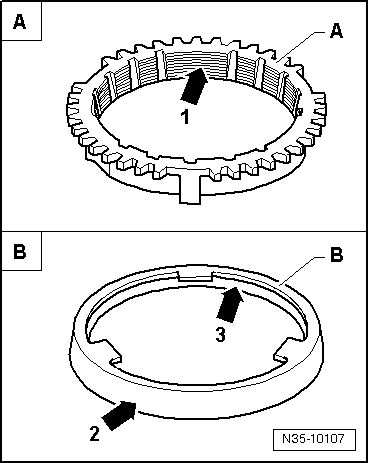

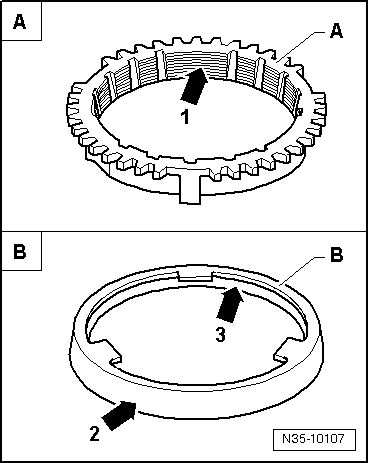

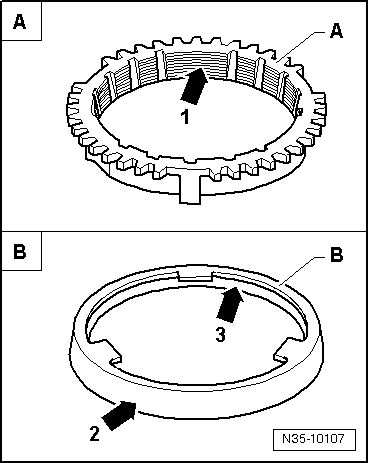

| Check grooves -arrow 1- on synchronizer ring -A-, or check the inside of the ring for flattened parts (grooves worn). |

| t

| When installing the intermediate ring -B-, check outer contact surface -arrow 2- and inner contact surface -arrow 3- for grooves, blue coloring (caused by overheating) and other damages. |

| t

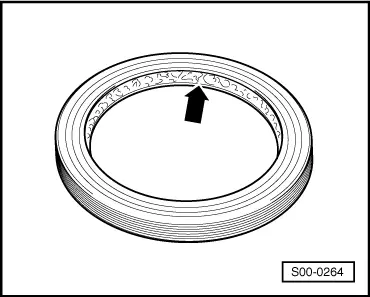

| Insert moist with some gearbox fluid. |

| t

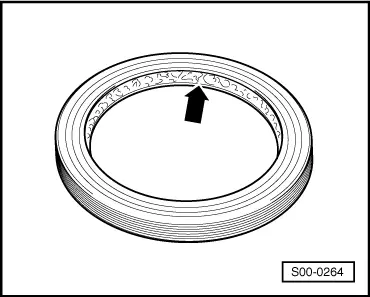

| Clean and heat on a heating plate or with the induction heater unit e.g. -VAS 6414- to approx. 100°C before pressing on. |

| t

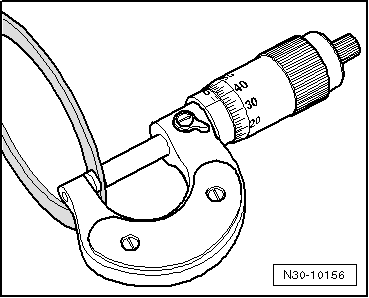

| The temperature can be checked with a temperature measuring instrument. |

| t

| Check fitting position. |

| t

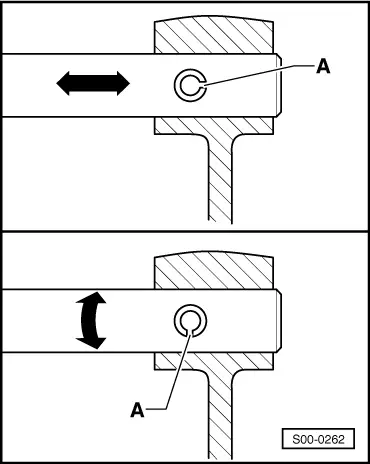

| Check 1st to 5th gear sliding gears after assembly for low axial play or smooth operation. |

| t

| When removing gearbox, remove slave cylinder, do not detach the hoses. |

| t

| If the slave cylinder with connected hydraulic line is removed, do not depress the clutch pedal. Otherwise the tappet is pressed out of the slave cylinder. |

| t

| Do not tilt the clutch pressure plate; release and tighten crosswise in small stages. |

| t

| If the clutch pedal does not return to its initial position after the coupling procedure - clutch pedal in home position - the clutch control must be bled (further measures → Chapter). |

| t

| In order to reduce unpleasant odours if the clutch is burnt, thoroughly clean the clutch housing as well as the flywheel and the engine on the side of the gearbox. |

|

|

|