| t

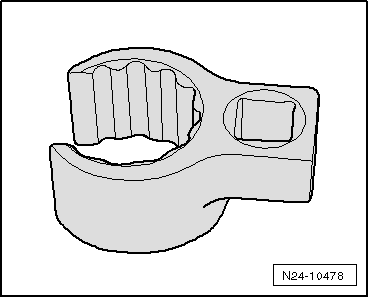

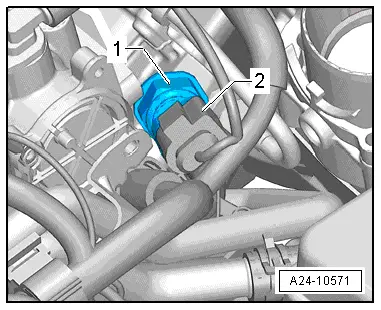

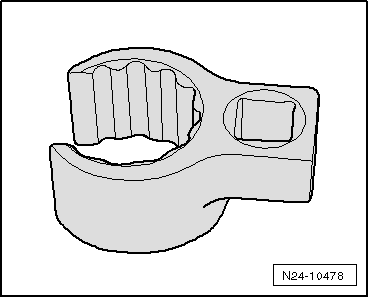

| Open ring spanner with 3/8" drive, wrench size 27 mm |

| t

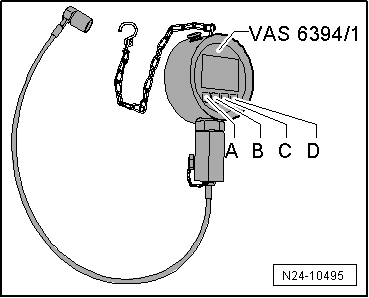

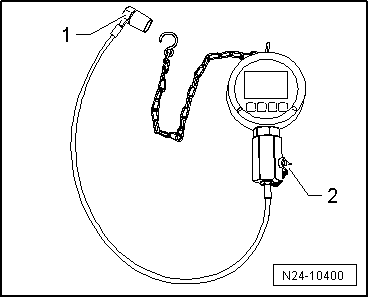

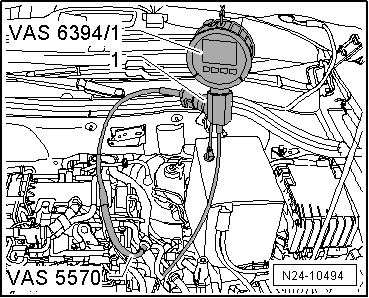

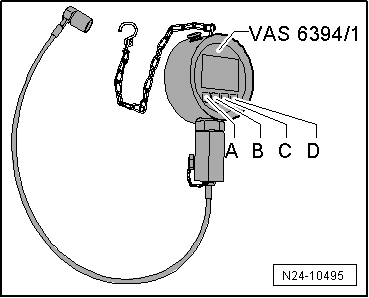

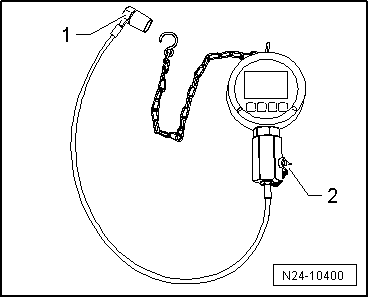

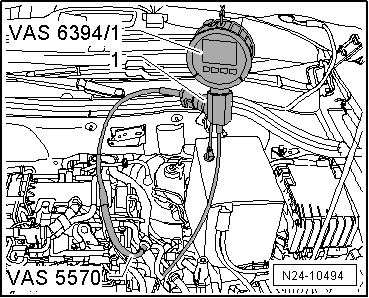

| Pressure sensor tester, e.g. -VAS 6394- (includes digital manometer - VAS 6394/1-) |

| t

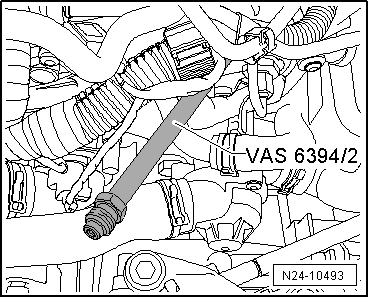

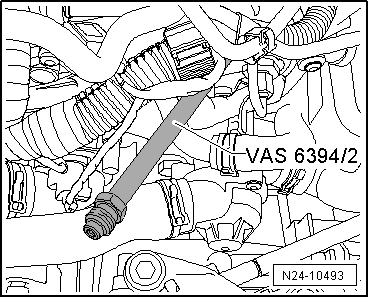

| Adapter, e.g. -VAS 6394/2- |

| t

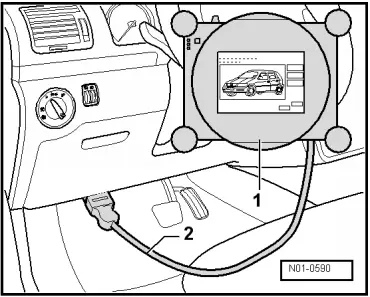

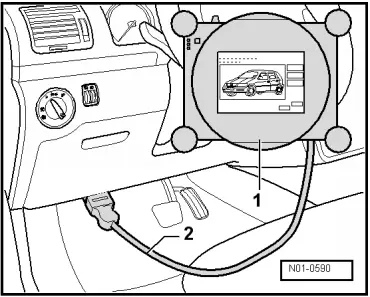

| Test adapter, e.g. -VAS 5570- |

| t

| Vehicle diagnosis, measurement and information system -VAS 505X- |

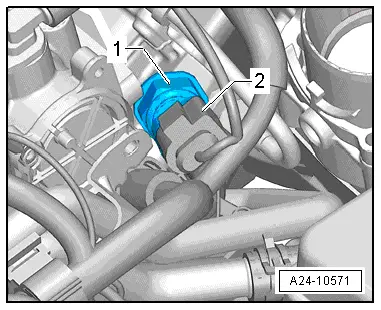

WARNING | The injection system consists of a high pressure part (max. pressure of 12 MPa = 120 bar) and a low pressure part (pressure of approx. 0.6 MPa = 6 bar). |

| t

| Before opening the high pressure area, e.g. removing the high pressure pump, the fuel distributor, the injection valves, the fuel pipes or the fuel pressure sender -G247-, the fuel pressure in the high pressure area with a remaining pressure of approx. 0.6 MPa (6 bar) must be reduced. |

| t

| The procedure for this is described in the chapter „release pressure in the high pressure area of the fuel system“ → Chapter. |

|

|

|

|

Note

Note

Note

Note