Esteem GLX Wagon L4-1.8L (1999)

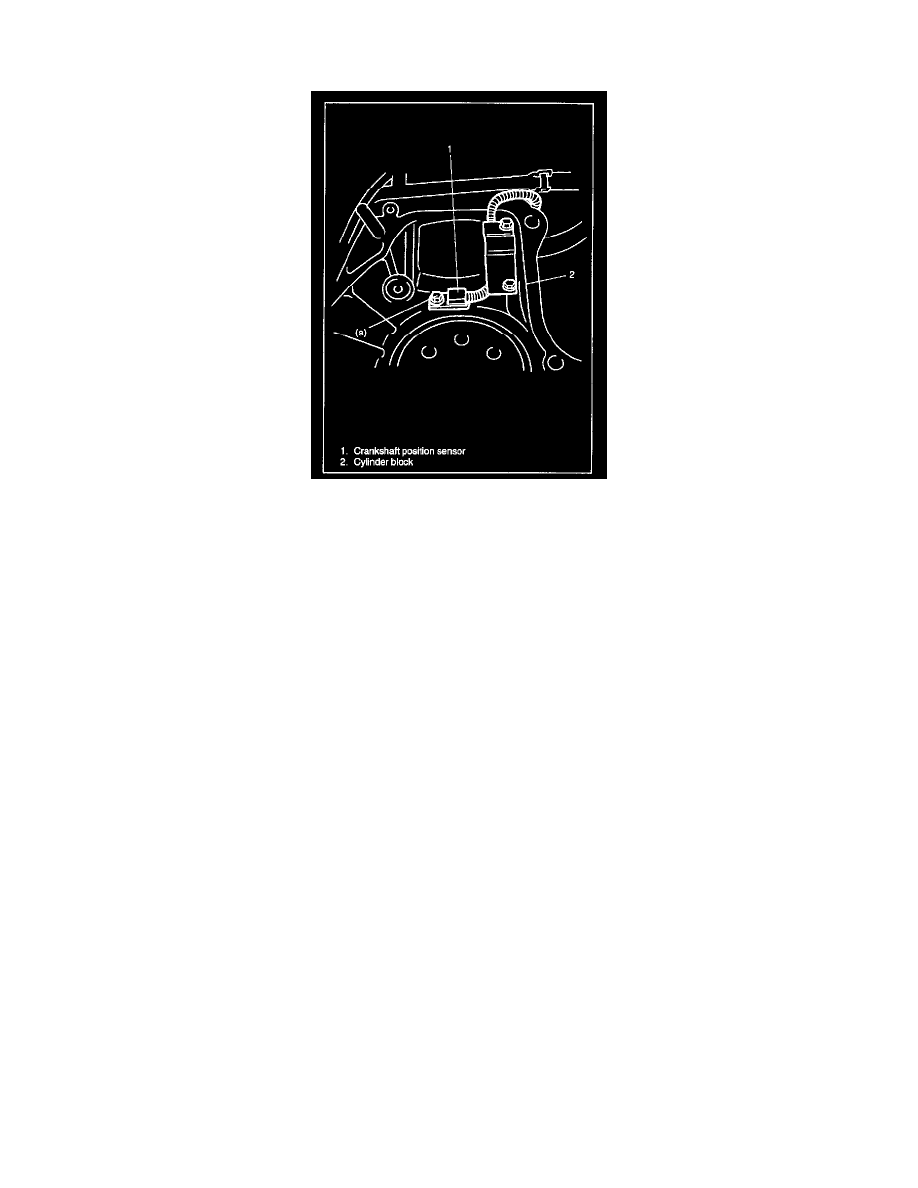

Crankshaft Position Sensor: Service and Repair

REMOVAL

1. Remove transmission from vehicle and then remove flywheel or drive plate from crankshaft.

2. Disconnect connector from crankshaft position sensor.

3. Remove crankshaft position sensor from cylinder block.

INSTALLATION

Reverse removal procedure noting the following.

-

Check to make sure that crankshaft position sensor is tree from any metal particles and damage.

-

Apply engine oil to O-ring of sensor.

-

Install crankshaft position sensor to cylinder block.

Tightening Torque

(a): 6 Nm (0.6 kg-m, 4.5 lb-ft)

-

Connect connector and fix wire harness with clamp securely.