4 Runner 2WD L4-2693cc 2.7L DOHC MFI (1997)

(a)

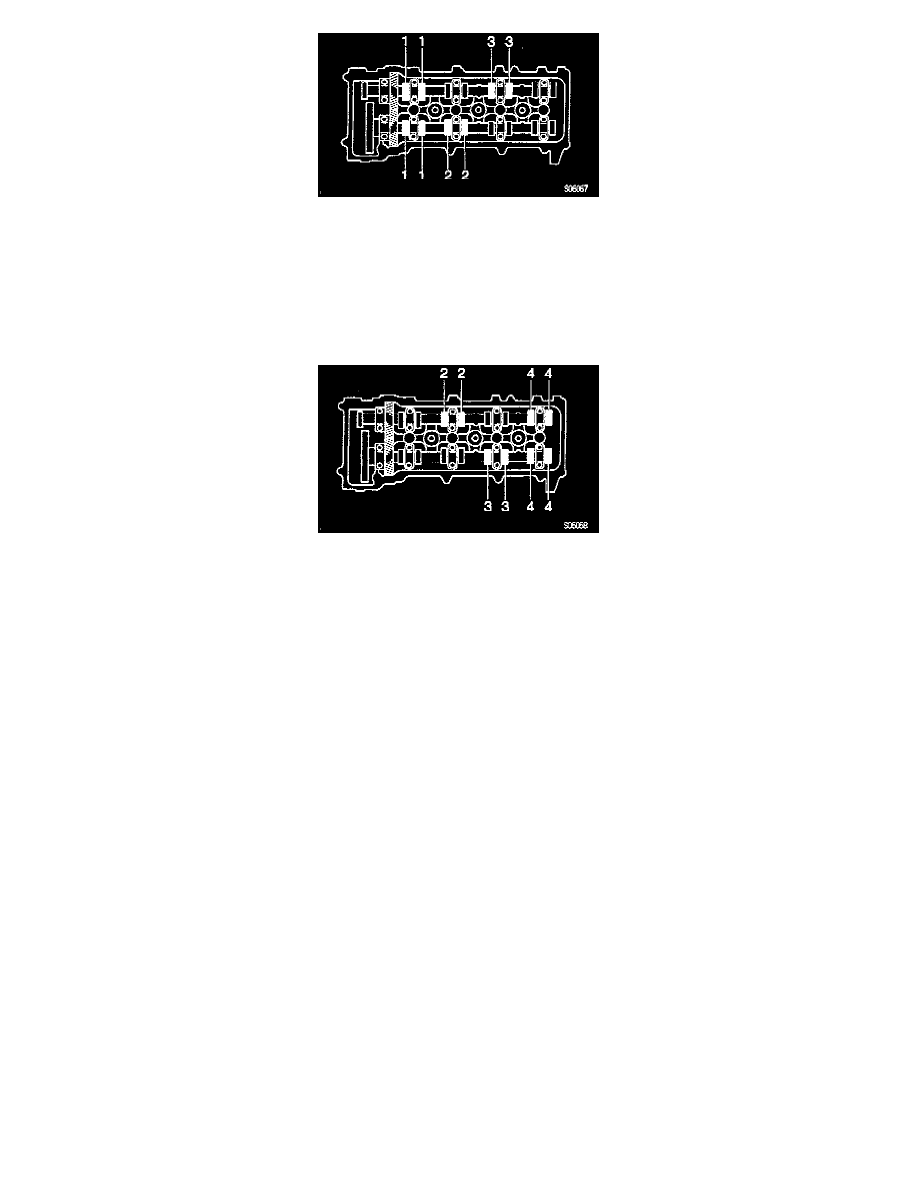

Check only the valves indicated.

-

Using a feeler gauge, measure the clearance between the valve lifter and camshaft.

-

Record the out-of-specification valve clearance measurements. They will be used later to determine the required replacement adjusting

shim.

Valve clearance (Cold):

Intake: 0.15 - 0.25 mm (0.006 - 0.010 inch)

Exhaust: 0.25 - 0.35 mm (0.010 - 0.014 inch)

(b) Turn the crankshaft pulley 1 revolution (360°) and align its groove with timing mark "O" of the timing chain cover.

(c)

Check only the valves indicated as shown. Measure the valve clearance. (See procedure in step (a))

8. Adjust valve clearance.

9. Reinstall cylinder head cover.

10. Reconnect engine wire.

11. Reinstall high-tension cords to spark plugs.

12. Reinstall PCV hoses.

13. Reinstall intake air connector.