Previa Van LE 4WD L4-2438cc 2.4L DOHC SC MFI (1997)

A/C Idle Up Valve: Component Tests and General Diagnostics

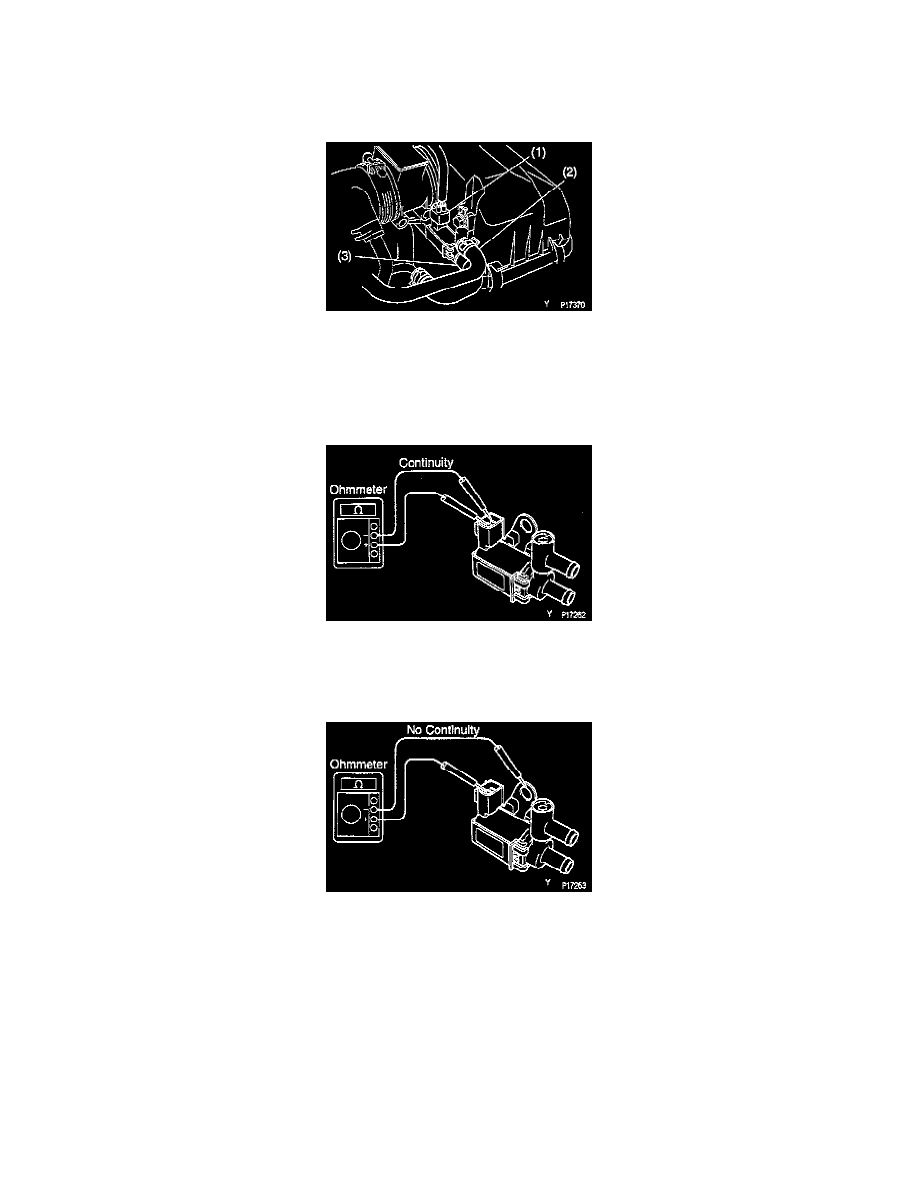

A/C IDLE-UP VALVE INSPECTION

1. Remove idle-up valve.

(a) Disconnect the following connector and hoses:

(1) Idle-up valve connector.

(2) Air hose (from air cleaner hose) from port E of idle-up valve.

(3) Air hose (from air connector vent pipe) from port F of idle-up valve.

(b) Remove the bolt and idle-up valve.

2. Inspect idle-up valve.

A. Inspect idle-up valve for open circuit.

Using an ohmmeter, check that there is continuity between the terminals.

Resistance: At 20° C (68° F): 30 - 34 ohms

If there is no continuity, replace the idle-up valve.

B. Inspect idle-up valve for ground.

Using an ohmmeter, check that there is no continuity between each terminal and the body.

If there is continuity, replace the idle-up valve.

C. Inspect idle-up valve operation.