Supra L6-2997cc 3.0L DOHC MFI (1998)

Oil Control Valve: Component Tests and General Diagnostics

On-Vehicle Inspection

ON-VEHICLE INSPECTION

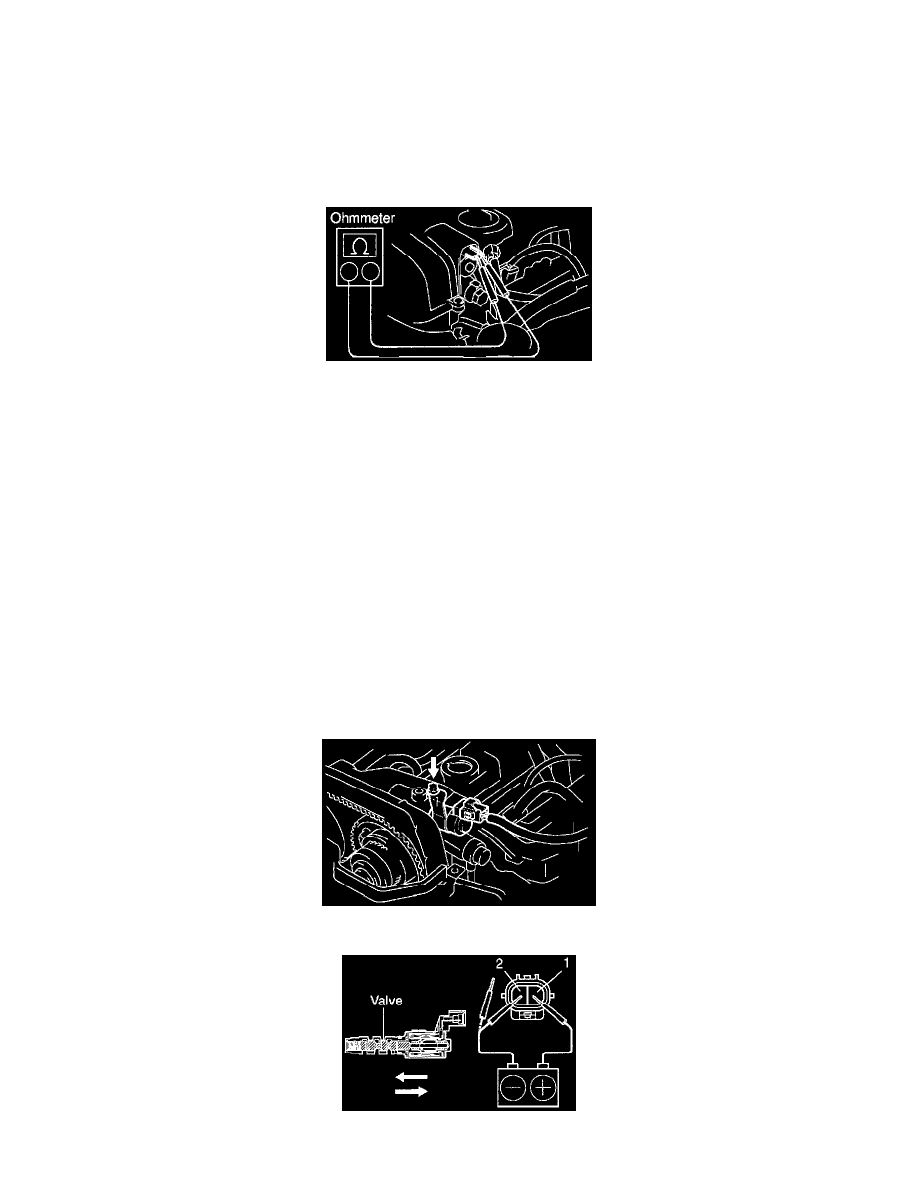

1. INSPECT CAMSHAFT TIMING OIL CONTROL VALVE RESISTANCE

(a) Disconnect the oil control valve connector.

(b) Using an ohmmeter, measure the resistance between the terminals.

Resistance: 5.5- 12 Ohms at 20°C (68°F)

If the resistance is not as specified, replace the valve.

(c) Reconnect the oil control valve connector.

2. INSPECT VVT-1 OPERATION

(a) Allow the engine to warm up to normal operating temperature.

(b) Check that the engine stalls or becomes in rough-idling state when the battery positive voltage is applied to the oil control valve with the

engine idling.

If operation is not as specified, check the oil control valve, VVT-1 pulley, intake camshaft, wiring and ECM.

Component Inspection

INSPECTION

1. REMOVE NO.3 TIMING BELT COVER

2. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

(a) Disconnect the oil control valve connector.

(b) Remove the bolt, oil control valve and O-ring.

Terminal Identification