Astra F

|

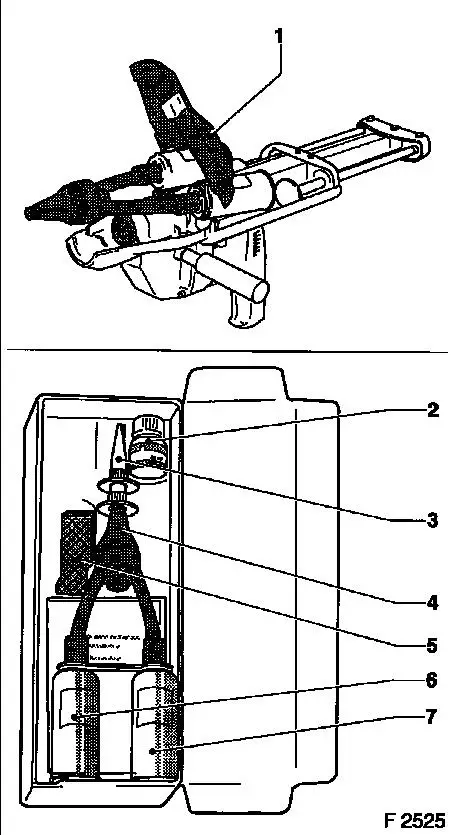

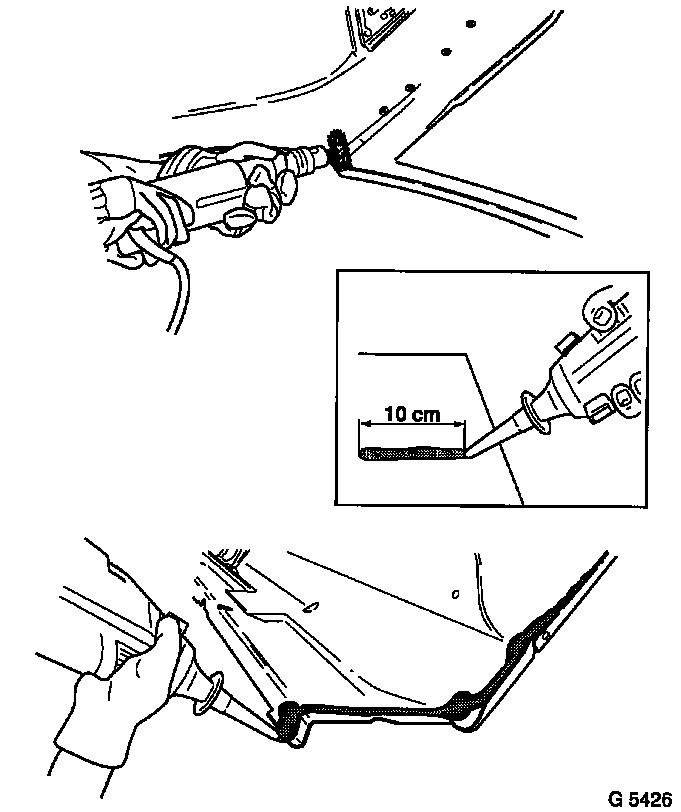

Body Repair Work by Means of Bonding and Welding "Bonding" means the joining of similar of different types of material by means of an inorganic or organic substance at room temperature or with moderate heating. The practical application of the bonding method is restricted to fully stressed parts of the body (e.g. external quarter panel). Bearing parts, e.g. frames, supports are excluded from this application. From Model Year 1998, the external quarter panels and wheel housing will be bonded at rear of the wheel cutout with packing adhesive - instead of using spot welding. The costs of repair work and the maintenance of a vehicle have a significant influence on its attraction to customers and hence on competitiveness. Therefore it is advisable to monitor the development of these costs continuously and to develop operating methods for reducing costs. The bonding technology developed by Opel and matched to the requirements of body repair work is the logical consequence of the consideration how to adopt modern techniques which have been found to be expedient and cost-reducing in other branches of industry, e.g. the aircraft industry, so they are useful for automobile technology and to implement them with success.

Body Repair Work by Means of Bonding and Welding (Continued)

Body Repair Work by Means of Bonding and Welding (Continued) General

Body Repair Work by Means of Bonding and Welding (Continued) Description of Work and Application:

Body Repair Work by Means of Bonding and Welding (Continued) Important:

|

||||||||||||||||||||