|

Crankshaft, Remove and Install

Remove Remove

| 1. |

Detach transmission from engine

| • |

with manual transmission

|

| • |

with automatic transmission

|

|

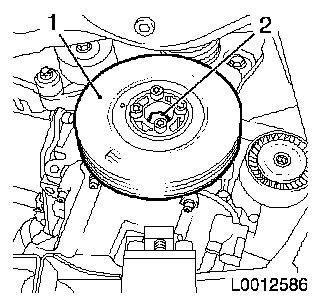

| 3. |

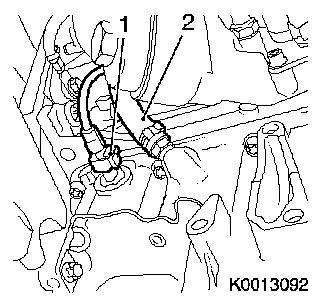

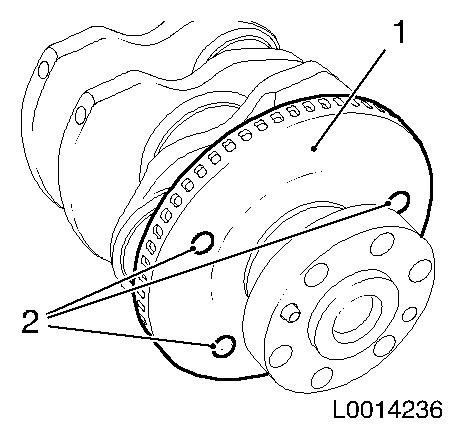

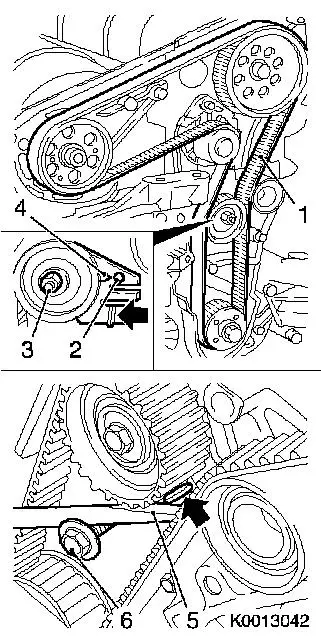

Remove torsional vibration damper (1)

| • |

Unscrew 4x bolts

Note: Counterhold

toothed belt drive gear at bolt (2)

|

|

|

|

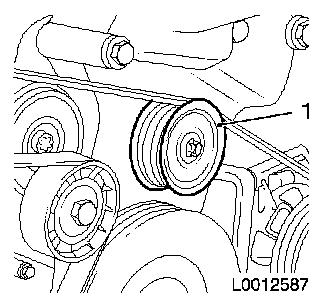

| 4. |

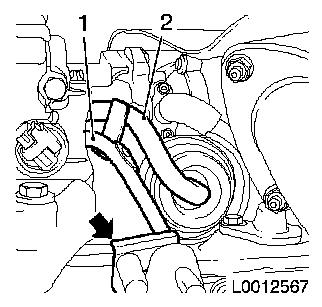

Remove ribbed V-belt guide roller (1)

|

|

|

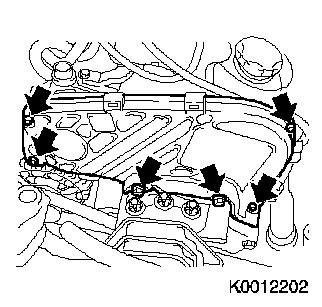

| 5. |

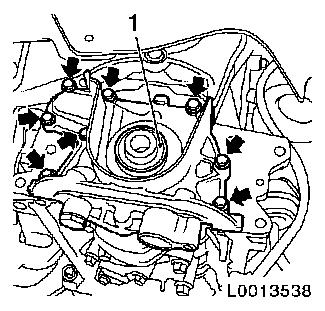

Remove toothed belt cover

| • |

Unscrew 6x bolt (arrows)

|

| • |

4x unclip camshaft sensor wiring harness

|

|

|

|

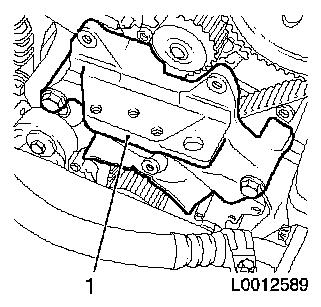

| 6. |

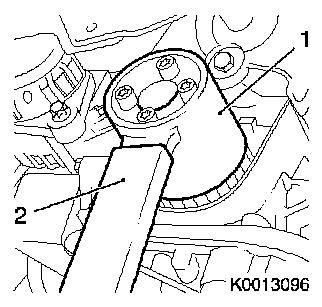

Remove engine damping block adapter (1)

| • |

Unscrew 5x bolts

Note: Note different

bolt lengths

|

|

|

|

| 7. |

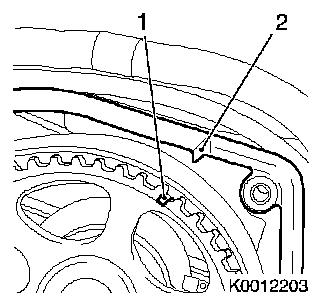

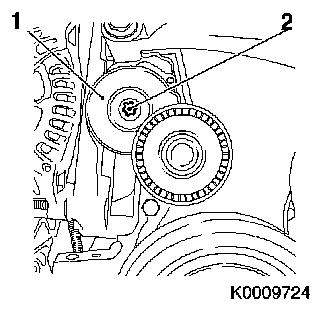

Set cylinder no. 1 to TDC of combustion stroke

Note: The mark on the

camshaft sprocket (1) must align with the mark on the cylinder head

cover (2).

|

|

|

| 8. |

Remove toothed belt (1)

| • |

Slacken the toothed belt tension roller

|

|

|

|

| 10. |

Vehicles with manual transmission: remove clutch

|

| 11. |

Remove KM-6263

| • |

Turn rotating spindle back to initial position

|

|

| 13. |

Vehicles with manual transmission: remove flywheel

|

|

|

| 14. |

Vehicles with automatic transmission: remove drive disc

|

|

|

| 15. |

Place collecting basin underneath.

|

| 16. |

Drain engine oil

| • |

Loosen oil drain bolt

Note: Unscrew the oil

drain bolt slowly until the oil drain hole is open

|

|

| 17. |

Disconnect residual oil quantity sensor wiring harness plug

(1)

|

| 18. |

Detach engine vent return hose (2)

|

|

|

| 19. |

Detach vacuum line (2) from oil dipstick guide tube (1)

|

| 20. |

Detach oil dipstick guide tube from oil pan

|

|

|

| 21. |

Remove oil pan

| • |

Unscrew 10x bolts (M8) with EN-46796

|

| • |

Unscrew 4x bolt (M6) with EN-46794

|

|

| 22. |

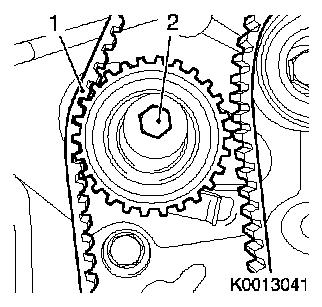

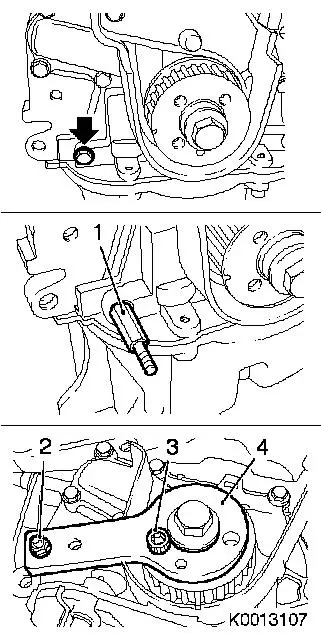

Attach EN-46730 (1) in conjunction

with KM-956-1 (2) to toothed belt drive

gear

|

| 23. |

Detach toothed belt drive gear

| • |

Unscrew bolt

Note: Left-handed

thread

|

| • |

Counterhold with EN-47630 in

conjunction with KM-956-1

|

| • |

Remove toothed belt drive gear with EN-47630

|

|

|

|

| 24. |

Remove ribbed V-belt tensioner (1)

| • |

Tension ribbed V-belt tensioner with KM-913-A

|

|

|

|

| 25. |

Remove oil pump

| • |

Unscrew 8x bolt (arrows)

|

| • |

Remove crankshaft seal ring (1)

|

|

|

|

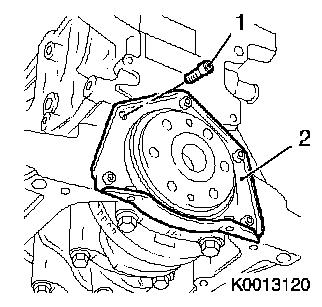

| 26. |

Remove bracket for rear crankshaft seal ring (2)

|

|

|

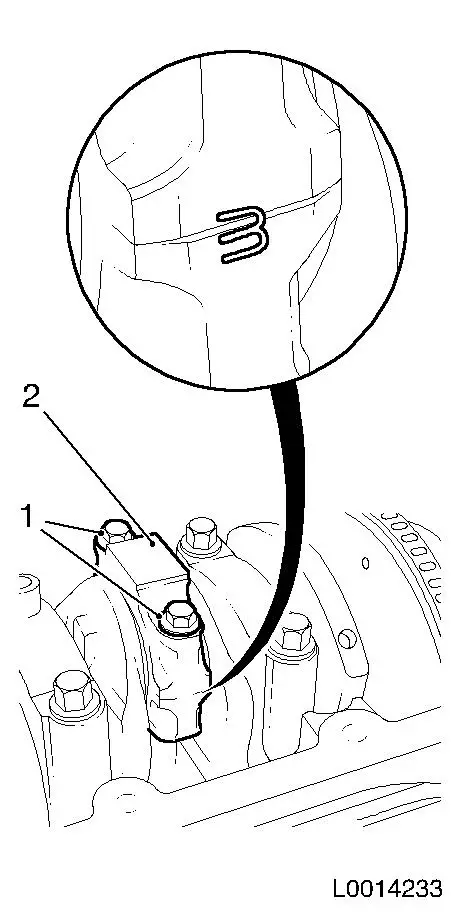

| 27. |

Detach 4x con-rod bearing cap (2) with con-rod bearing

shell

| • |

Unscrew 8x bolts (1)

Note: Note

identification mark on con-rod bearing cap and con-rod. Apply

identification mark if not present

|

|

|

|

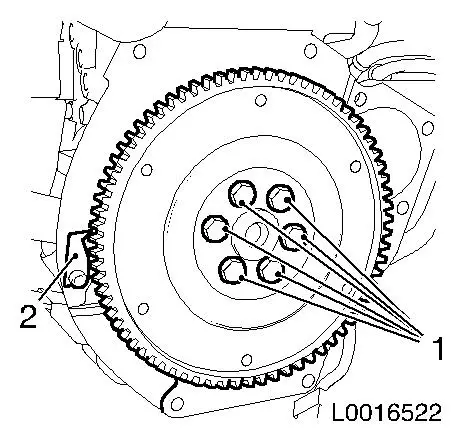

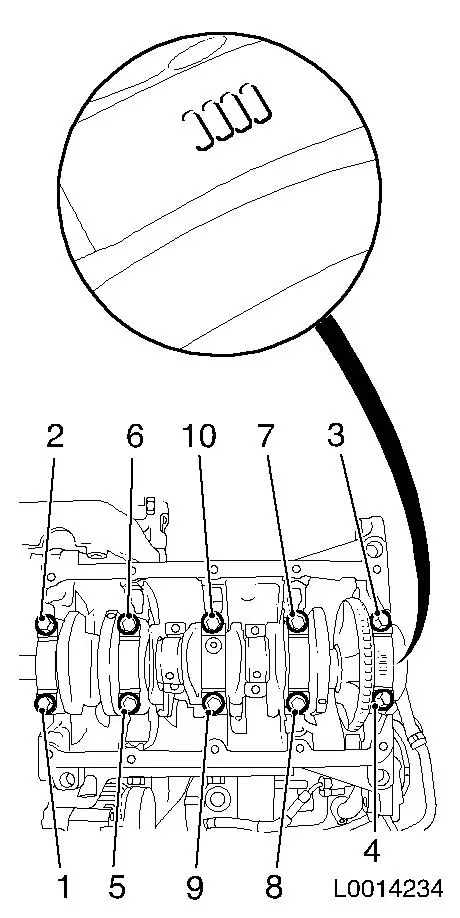

| 28. |

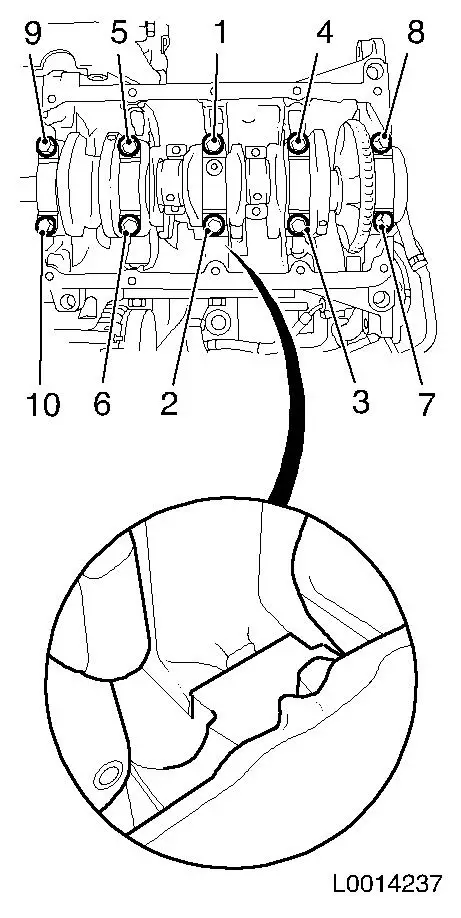

Remove 5x crankshaft bearing cap with crankshaft bearing

shell

| • |

Release 10x bolt in the order shown (1 - 10)

Note: Note marking on

crankshaft bearing cap

|

|

|

|

| 29. |

Remove crankshaft

Note: Place crankshaft

on wooden blocks

|

| 30. |

Remove 5x crankshaft bearing shell from cylinder block

|

| 32. |

Detach crankshaft pulse pick-up disc (1)

|

|

|

Install

Install

| 34. |

Install crankshaft pulse pick-up disc

| • |

Tighten 3x bolts

Note: Insert bolts with

bolt locking compound (red).

|

|

| 35. |

Replace 8x con-rod bearing shell

|

| 36. |

Replace 10x crankshaft bearing shell

| • |

5x crankshaft bearing cap

|

|

| 37. |

Insert 2x wear ring

| • |

Oil grooves point outwards

|

|

Important: Check installation

position

|

| 38. |

Insert crankshaft

| • |

Coat crankshaft journal with engine oil

Note: Ensure that the

bearing shells and wearing rings are correctly seated

|

|

Important: Note installation

position. Lug points to intake side

|

| 39. |

Install 5x crankshaft bearing cap

| • |

Tighten 10x new bolt in depicted sequence (1 – 10) 25 Nm + 100°

|

|

|

|

| 40. |

Install 4x con-rod bearing cap with con-rod bearing shell

| • |

Tighten 8x new bolt 25 Nm +

60°

Note: Note

identification on con-rod bearing cap and con-rod.

|

|

| 42. |

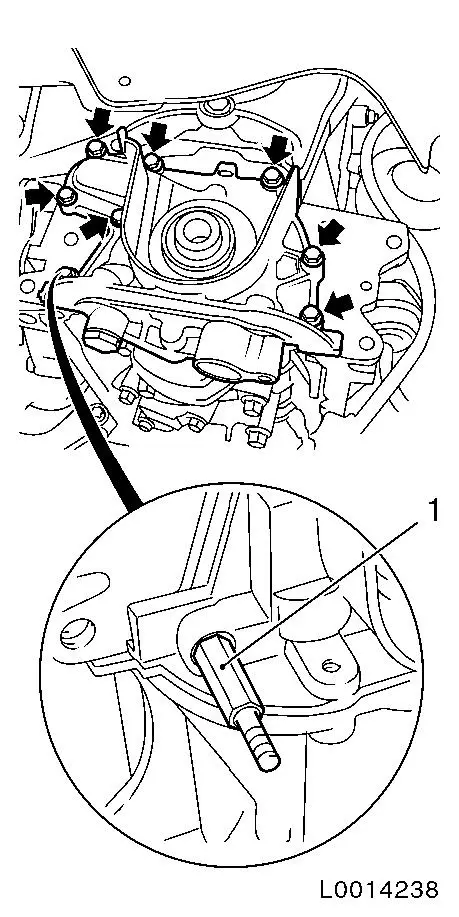

Install new bracket, rear crankshaft seal ring

| • |

Tighten 5x bolt 9 Nm

Note: Clean thread

before re-using and insert bolt with locking compound (red). The

maximum installation time including torque check is 10 minutes.

|

|

Important: Before fastening,

align oil pump housing with sealing surfaces of the oil pan on the

cylinder block

|

| 44. |

Install oil pump

| • |

Replace crankshaft seal

|

| • |

Tighten 7x bolt (arrows) 9 Nm

Note: Clean thread

before re-using and insert bolt with locking compound (red). The

maximum installation time including torque check is 10 minutes.

|

| • |

Tighten stud bolt (1) from EN-46788

|

| • |

Install oil intake pipe

|

|

|

|

| 45. |

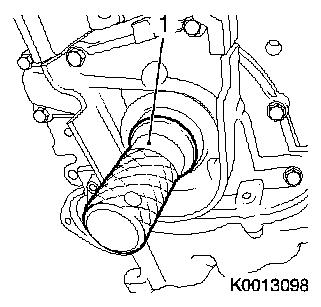

Install oil pump seal ring with EN-46793 (1)

|

|

|

| 46. |

Install ribbed V-belt tensioner

|

| 47. |

Replace toothed belt drive gear

Note: Note locking

| • |

Tighten bolt 340 Nm

Note: Left-handed

thread

|

| • |

Counterhold with EN-47630

|

|

| 48. |

Detach EN-46730 in conjunction with

KM-956-1 from toothed belt drive gear

|

| 49. |

Clean sealing surfaces.

|

| 50. |

Apply sealant

Important: Complete assembly work

within 10 minutes

|

| • |

Apply sealant to oil pan sealing surface

|

|

| 51. |

Install oil pan

| • |

Tighten 10x bolt (M10) 25 Nm

|

| • |

Tighten 4x bolt (M6) 9 Nm

|

|

| 52. |

Attach oil dipstick guide tube to oil pan

|

| 53. |

Attach engine vent return hose

|

| 54. |

Connect residual oil sensor wiring harness plug

|

| 56. |

Vehicles with manual transmission: install flywheel

Note: Note guide

sleeves

| • |

Tighten 6x new bolt 160 Nm

Note: Insert bolt with

locking compound (red). The maximum installation time including

torque check is 10 minutes.

|

|

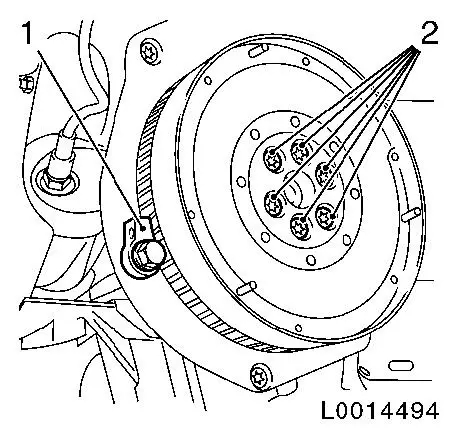

| 57. |

Vehicles with automatic transmission: install drive disc

| • |

Tighten 6x new bolt 160 Nm

|

|

| 58. |

Attach KM-6263

Important: Fasten KM-6263 but only to engine block, not to oil pan

|

| • |

Tighten 4x bolts

|

| • |

Insert clutch pin KM-6263-30 with

KM-6263-22

|

|

| 61. |

Remove toothed belt tightening roller

|

| 63. |

Install toothed belt tension roller

| • |

Insert tension roller in guide

|

| • |

Screw in bolt

Note: Insert bolt with

locking compound (red). The maximum installation time including

torque check is 10 minutes.

|

|

| 64. |

Set cylinder no. 1 to TDC of combustion stroke

Note: The mark on the

camshaft sprocket must align with the mark on the cylinder head

cover.

|

| 65. |

Install toothed belt

| • |

Observe prescribed direction of rotation

|

Important: Tightened end (1) must

be taut

|

| • |

Position toothed belt

|

|

| 66. |

Tension the toothed belt

| • |

Tension toothed belt tension roller

Note: Push adjusting

lever in direction of arrow with a screwdriver (5) until pointer

(4) of toothed belt tension roller aligns with mark (2).

|

| • |

Tighten bolt, toothed belt tension roller (3) 25 Nm

|

|

|

|

| 67. |

Check crankshaft setting with EN-46788

| • |

Unscrew oil pump bolt (arrow)

|

| • |

Tighten stud bolt (1) EN-46788

|

| • |

Attach positioning disk (4) EN-46788

|

| • |

Remove positioning disk EN-46788

|

|

|

|

| 68. |

Timing, Check

| • |

Turn crankshaft 720° in the

direction of rotation of the engine

|

| • |

Check camshaft position

| – |

The mark on the camshaft sprocket must align with the mark on

the cylinder head cover.

|

|

|

| 69. |

Install engine damping block adapter

Note: Note differing

bolt lengths.

| • |

Tighten 3x bolt (M10) 50 Nm

|

| • |

Tighten 2x bolt (M8) 25 Nm

|

|

| 70. |

Install toothed belt cover

| • |

4x clip in camshaft sensor wiring harness

|

|

| 71. |

Install ribbed V-belt guide roller

|

| 72. |

Install torsional vibration damper

Note: Observe correct

fitting position

| • |

Tighten 4x bolt 25 Nm

Note: Counterhold

toothed belt drive gear at bolt

|

|

| 74. |

Attach transmission to engine

| • |

with manual transmission

|

| • |

with automatic transmission

|

|

| 75. |

Replenish and correct engine oil

|

|