|

Crankshaft End Play, Check

Note: Crankshaft

removed

Install

Install

| 1. |

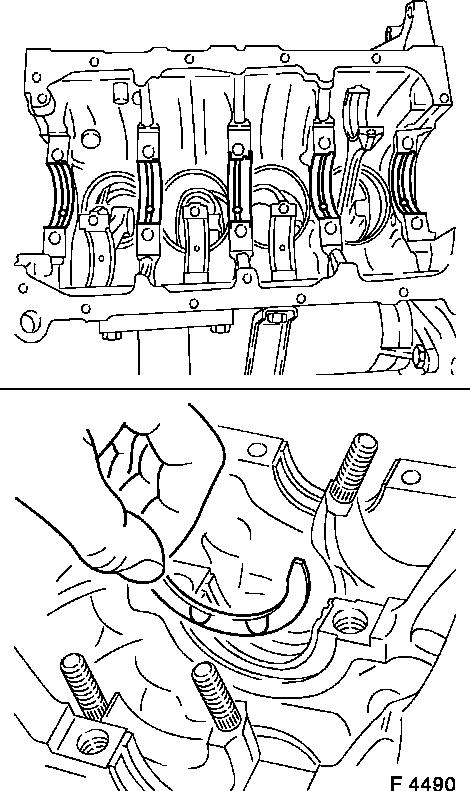

Insert 10x crankshaft bearing shell in cylinder block and

crankshaft bearing caps

| • |

Note mark and allocation

|

| • |

Note position of axial bearing

|

|

| 2. |

Insert crankshaft into cylinder block

| • |

Insert 2x wear ring

Note: Oil grooves point

outwards

|

|

|

|

| 3. |

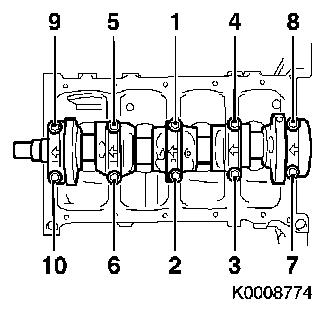

Attach 5x crankshaft bearing cap

| • |

Note marking and allocation. Arrows point to engine timing

side

|

| • |

Tighten 10x bolts in the specified tightening sequence (1-10)

39 Nm + 60°

Note: It is not

necessary to replace the bolts when aligning the crankshaft

|

|

|

|

| 4. |

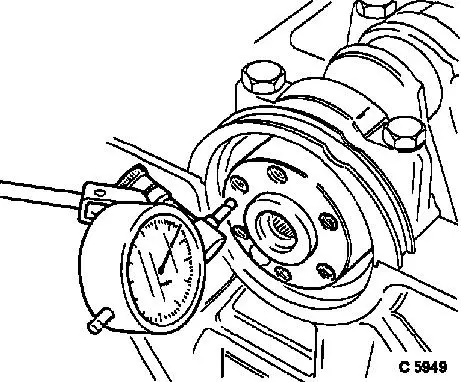

Attach MKM-571-B

| • |

Install MKM-571-B in bracket

|

| • |

Attach bracket to cylinder block on the transmission side

|

|

|

|

Measure

Measure

| 5. |

Adjust MKM-571-B

| • |

Position plunger on crankshaft flange

|

| • |

Attach MKM-571-B with

pre-tensioning

|

|

| 6. |

Measure longitudinal play of crankshaft

| • |

Read off test value

Note: Repeat

measurement several times. Permissible crankshaft end play

|

|

| 8. |

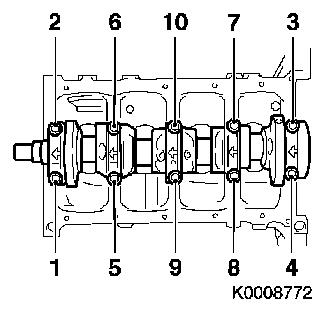

Remove 5x crankshaft bearing cap

| • |

Unscrew 10x bolts in the specified sequence (1-10)

|

|

|

|

| 9. |

Remove crankshaft from cylinder block

| • |

Take out 2x wearing ring

|

|

| 10. |

Take 10x crankshaft bearing shell out cylinder block and

crankshaft bearing caps

| • |

Note mark and allocation

|

|

|