|

Removing and installing both camshafts

Important: When

working on the fuel system it is essential to pay attention to

cleanliness as even the smallest dirt particles can lead to faults

in engine operation or in the fuel system. Open fuel connections

must be sealed with appropriate plugs from the Opel Parts Catalogue

(catalogue number: 45 06 154 / part number: 9201697). Sealing plugs

are only intended to be used once.

Remove Remove

| 2. |

Disconnect battery

| • |

Detach earth connection from earth terminal

|

|

| 3. |

Raise vehicle by its full height

|

| 4. |

Detach the lower engine cover and right engine splash guard

|

| 5. |

Place collecting basin underneath.

|

| 6. |

Drain coolant

| • |

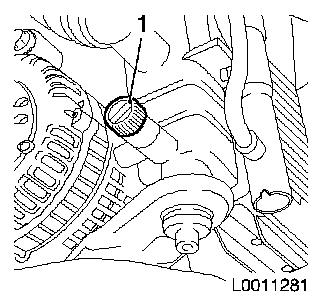

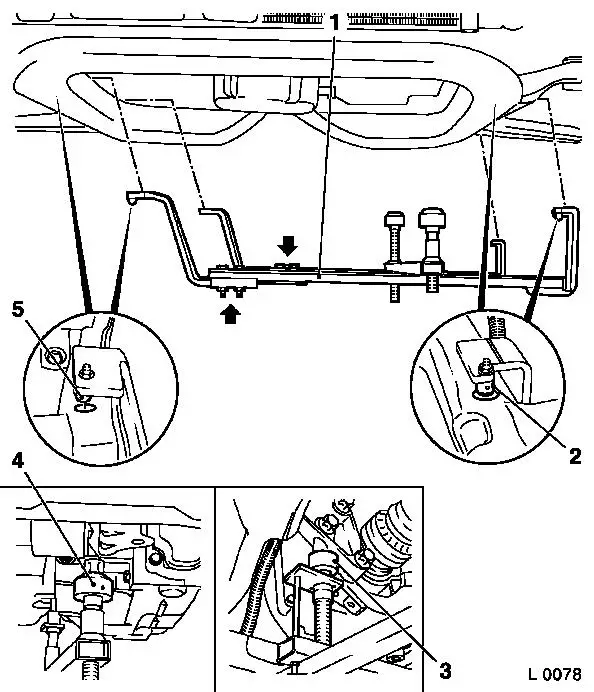

Open drain bolt on radiator (1)

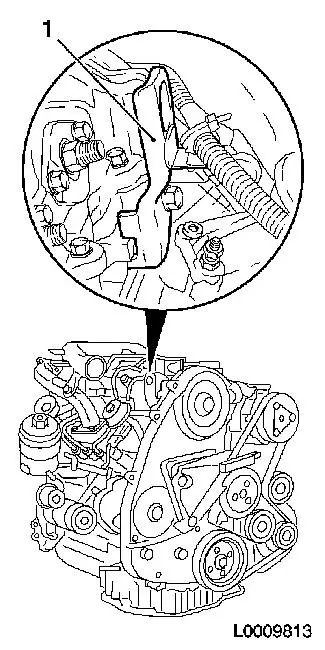

|

|

|

|

| 7. |

Attach the lower engine cover and right engine splash guard

|

| 8. |

Lower vehicle by its full height

|

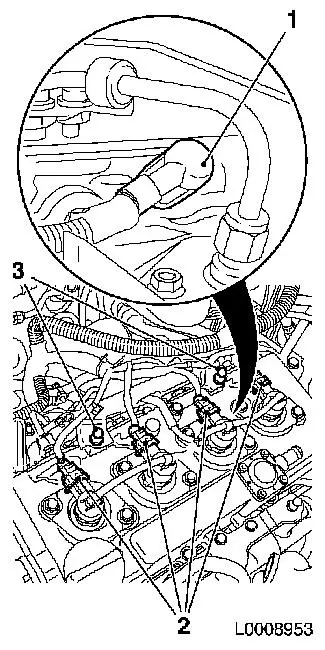

| 9. |

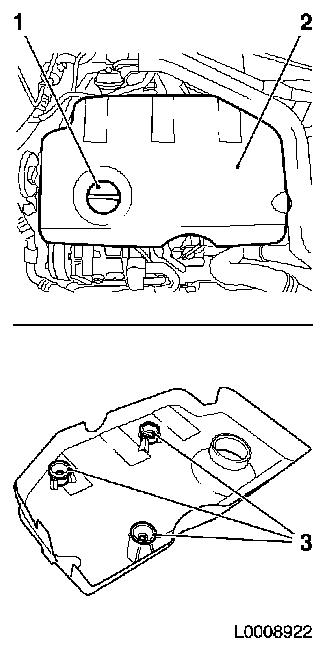

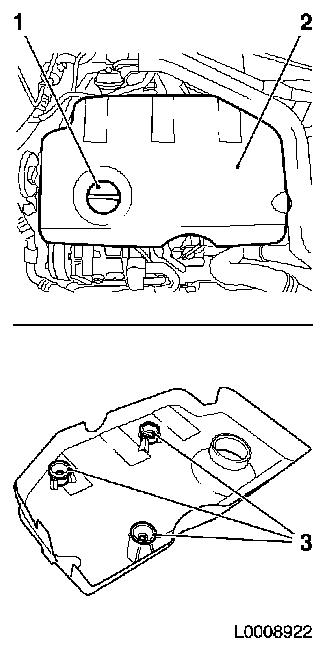

Remove engine cover (2)

| • |

Detach oil filler port closure cap (1)

|

| • |

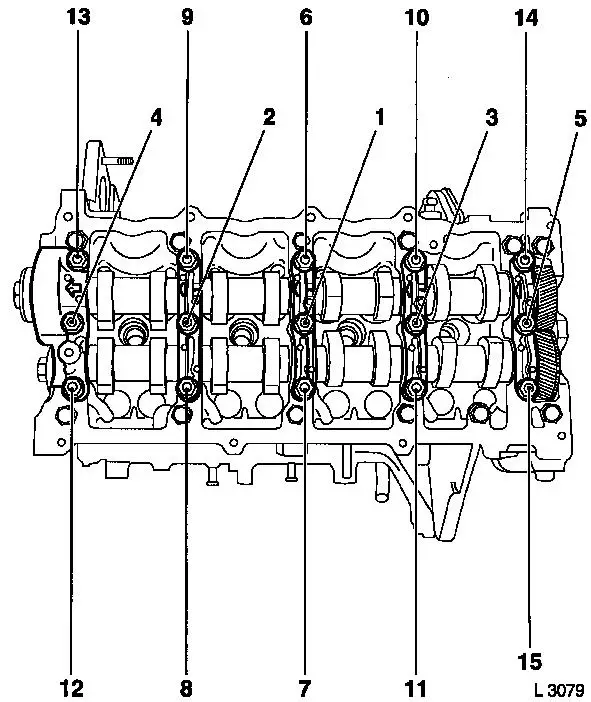

Pull off engine cover

Note: Rubber retainers

(3) must remain on engine cover

|

| • |

Attach oil filler port closure cap

|

|

|

|

| 10. |

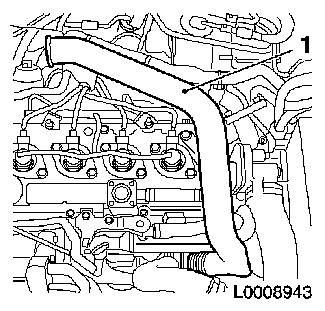

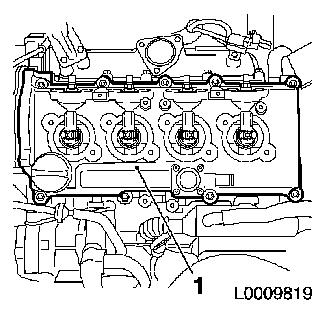

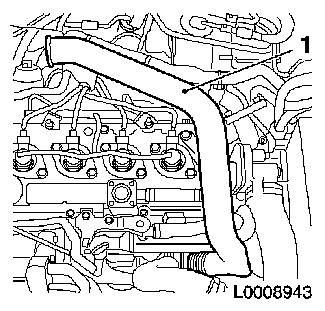

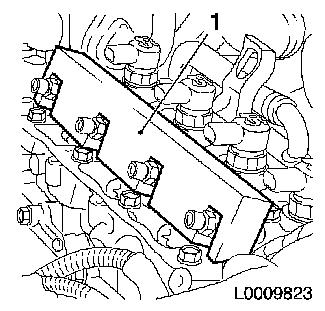

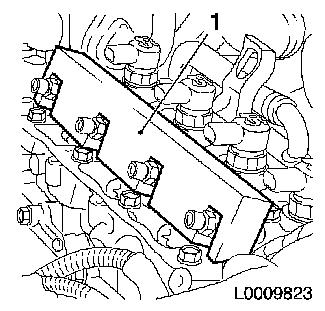

Remove air intake manifold (1)

|

|

|

| 11. |

Remove charge air pipe (1)

|

|

|

| 12. |

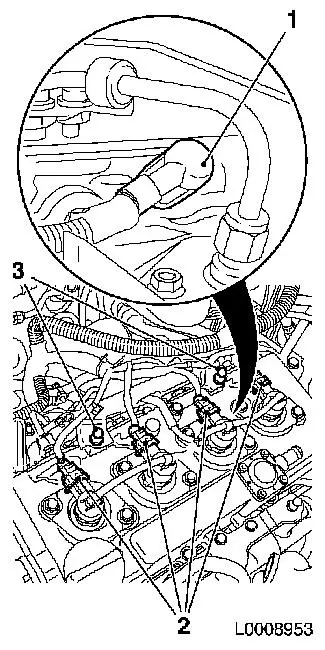

Detach wiring harness for injectors

| • |

Disconnect 4x wiring harness plugs for injector (2)

|

| • |

Disconnect 4x wiring harness plug for glow plug (1) with KM-717

|

| • |

Push wiring harness to one side

|

|

|

|

| 13. |

Place collecting basin underneath.

|

Important: After detaching the

pressure lines, seal off injector and pressure chamber openings

with protective caps

1)

|

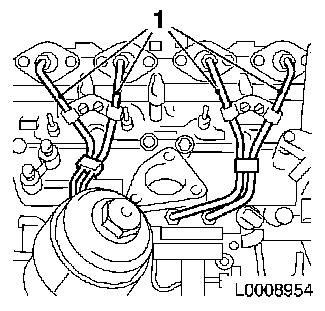

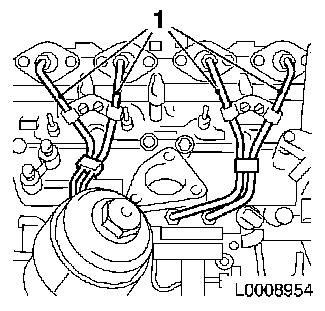

| 14. |

Remove high pressure lines (1), pressure chamber to

injectors

| • |

Unscrew 8x union nut with KM-812 or

KM-6098

|

| • |

Take out pressure lines

|

| • |

Seal 4x pressure chamber opening with protective cap

|

| • |

Seal 4x injector opening with protective cap

|

|

|

|

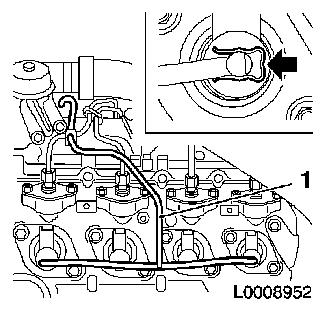

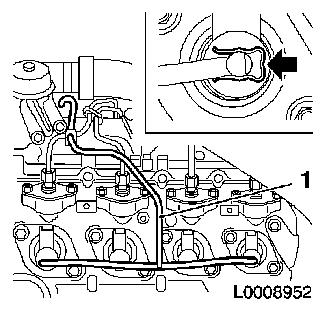

| 15. |

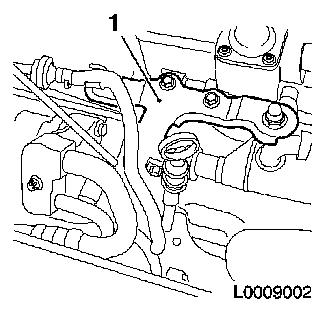

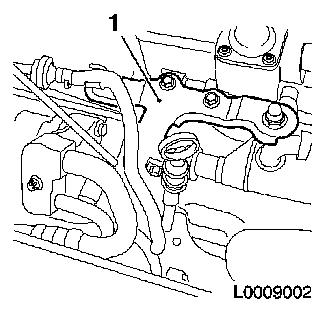

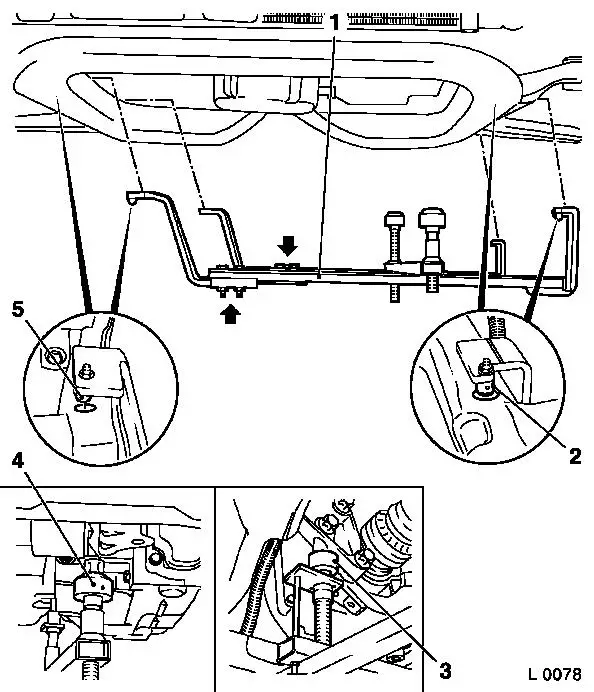

Detach fuel return line (1)

| • |

Detach 4x fuel return line from injector

| – |

Press 4x retaining clamps in direction of arrow

|

|

| • |

Detach fuel return line from pressure chamber

|

| • |

Unscrew 2x bolts

Note: Note different

bolt lengths

|

|

|

|

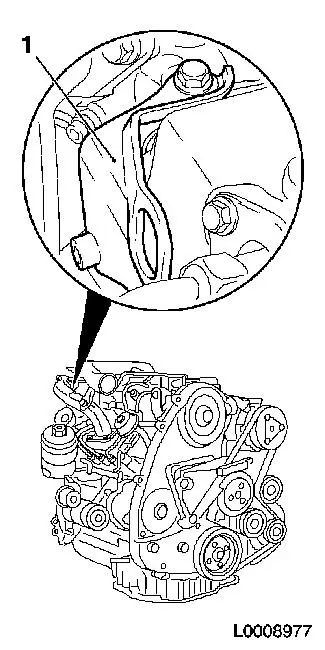

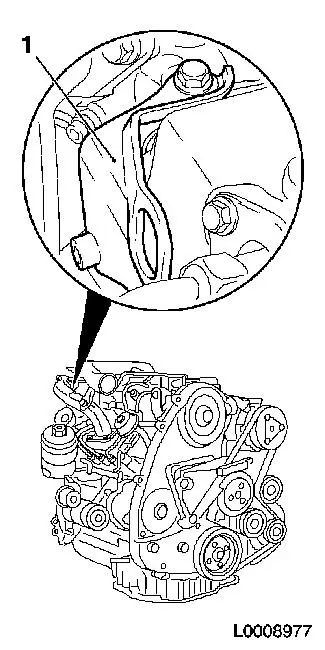

| 16. |

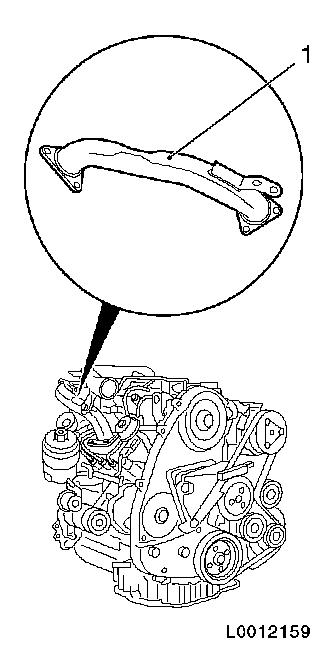

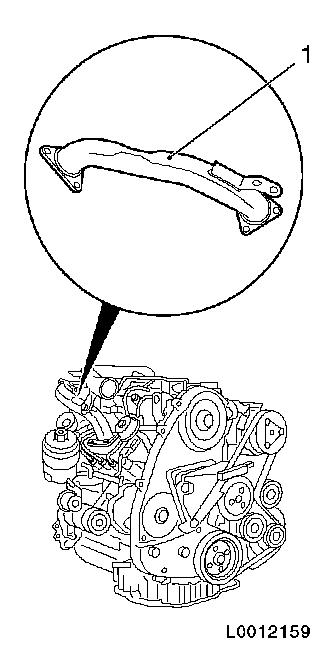

Remove rear right engine transport shackle (1)

|

|

|

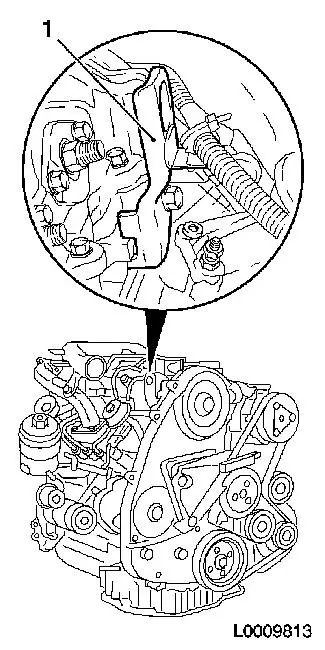

| 17. |

Remove rear left engine transport shackle (1)

|

|

|

| 18. |

Remove bracket, oil dipstick guide tube (1)

| • |

Remove oil dipstick guide tube

|

| • |

Detach bracket, oil dipstick guide tube, from camshaft

housing

|

|

|

|

| 19. |

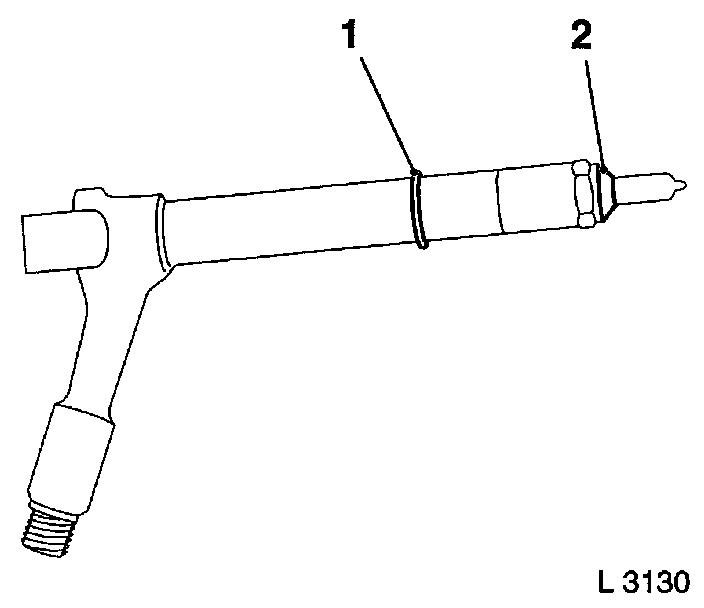

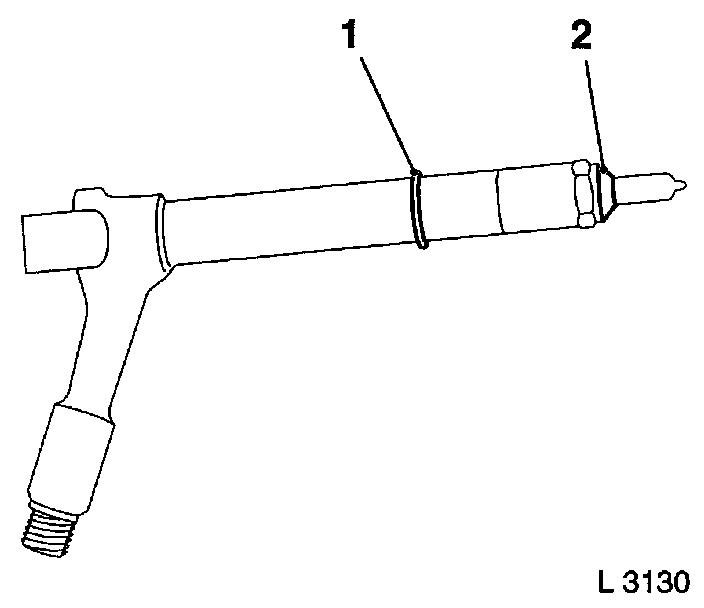

Remove 4x seals, connection for injectors (1)

|

|

|

| 20. |

Remove 4x seal, injectors (1)

|

|

|

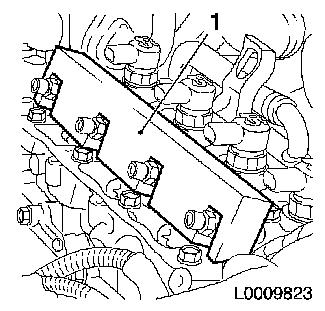

| 21. |

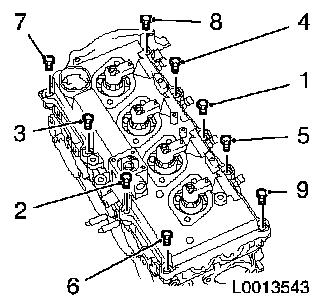

Remove camshaft housing cover (1)

| • |

Unscrew 11x bolts

Note: Note different

bolt lengths

|

|

|

|

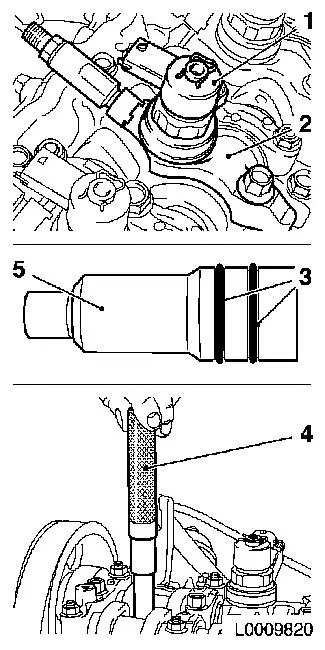

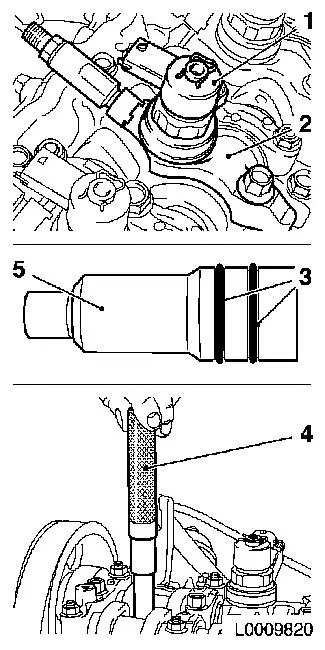

| 22. |

Remove 4x injector (1)

Note: Mark

injectors

| • |

Remove 4x bracket, injector (2)

| – |

Unscrew 4x bolts

Note: If a heat

protection sleeve (5) also has to be removed when removing an

injector, the gaskets (3) must be replaced and the heat protection

sleeve must be hammered into the cylinder head with KM-6357 (4)

|

|

|

|

|

| 23. |

Raise vehicle by its full height

|

| 24. |

Detach the lower engine cover and right engine splash guard

|

| 25. |

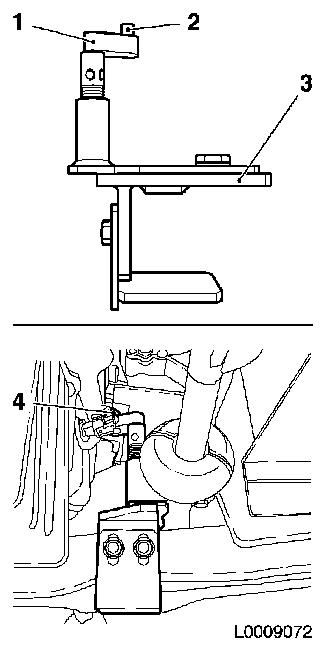

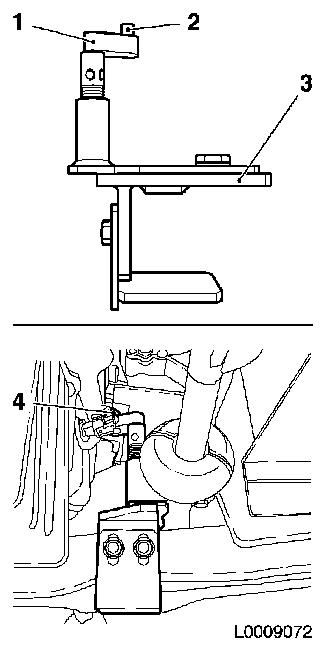

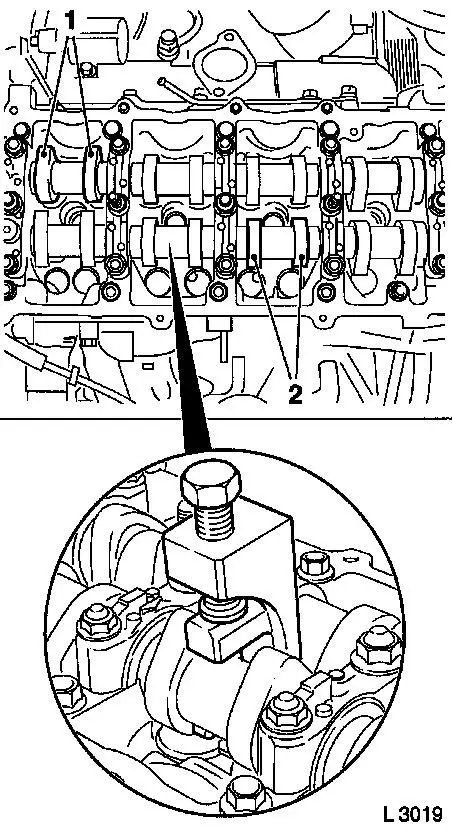

Insert KM-6173 (3)

| • |

Align support bearing (1)

|

| • |

Raise support bearing until journal (2) sits flush in mount

(4)

|

|

|

|

| 26. |

Attach KM-6001-A (1)

Note: Attaching

KM-6001-A guarantees perfect alignment of the drive unit with the

front axle body

| • |

Slacken 4x bolts (arrows) in adjusting rails

|

| • |

Insert KM-6001-A

| – |

Insert journals (2) and (5) in guide holes in front axle

body

|

|

| • |

Tighten 4x bolts in adjusting rails

|

| • |

Adjust support bearings, front (4) and rear (3)

| – |

Raise support bearings up to the stop on the guide journals

Note: The guide

journals must be seated free from play in the support bearings

|

|

|

|

|

| 27. |

Lower vehicle by its full height

|

| 28. |

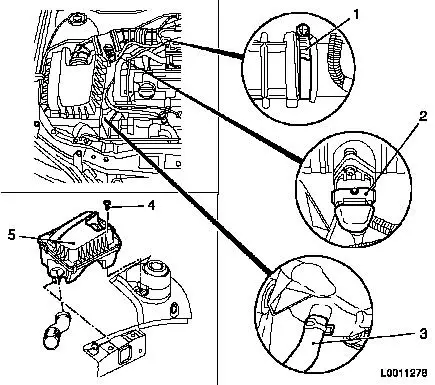

Remove air cleaner housing (5) with air intake hose

| • |

Disconnect wiring harness plug (2) from hot film mass air flow

meter

|

| • |

Detach air intake hose from air intake pipe

|

| • |

Detach air cleaner housing from wheel housing

|

| • |

Detach water drain hose (3) from air cleaner housing

|

|

|

|

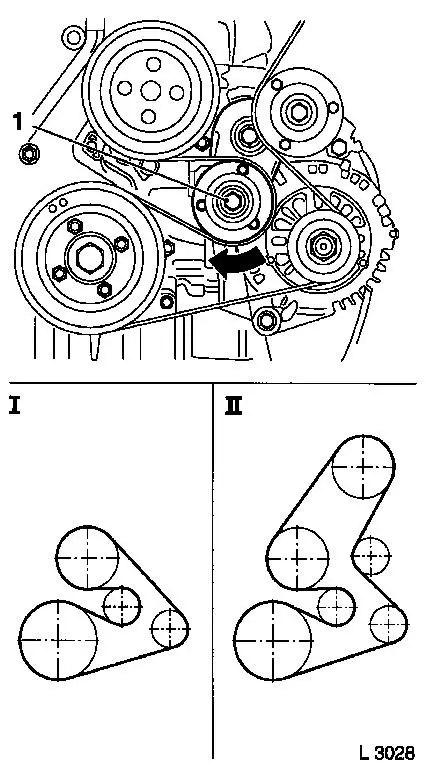

| 29. |

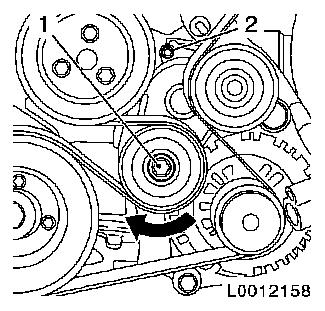

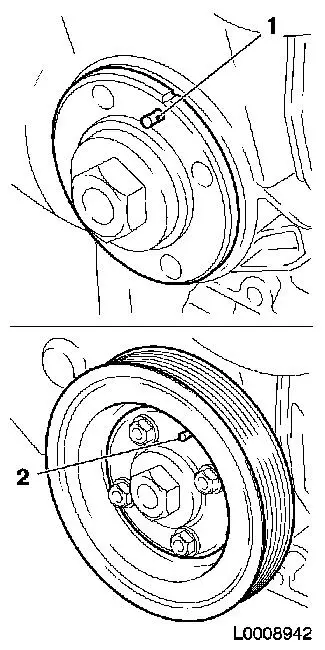

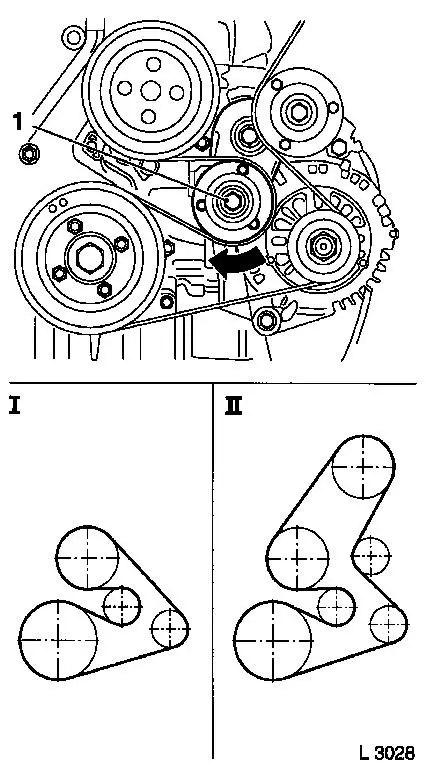

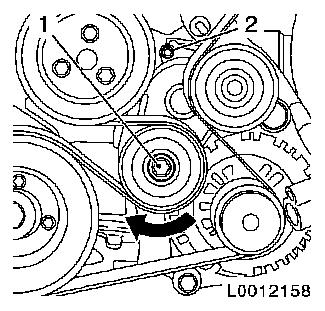

Remove ribbed V-belt

| • |

Mark direction of rotation

|

| • |

Apply tension to ribbed V-belt tensioner via bolt (1) in the

direction of the arrow

|

| • |

Fix ribbed V-belt tensioner to bore (2)

|

|

|

|

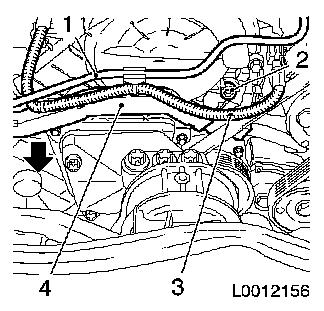

| 30. |

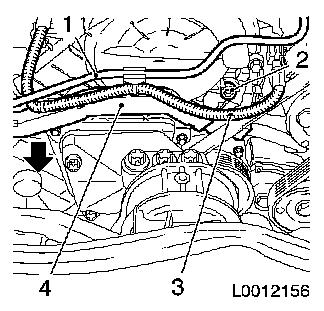

Detach wiring trough (4) from front toothed belt cover

(top)

| • |

Detach wiring harness (3)

| – |

Disconnect camshaft sensor wiring harness plug

|

|

| • |

Unclip wiring trough in direction of arrow

|

|

|

|

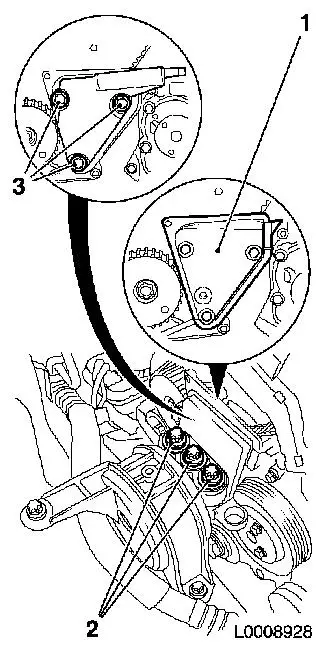

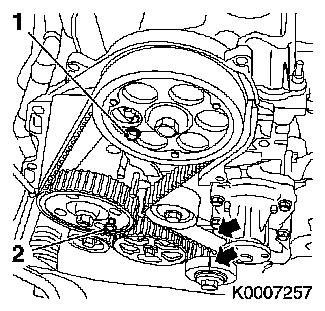

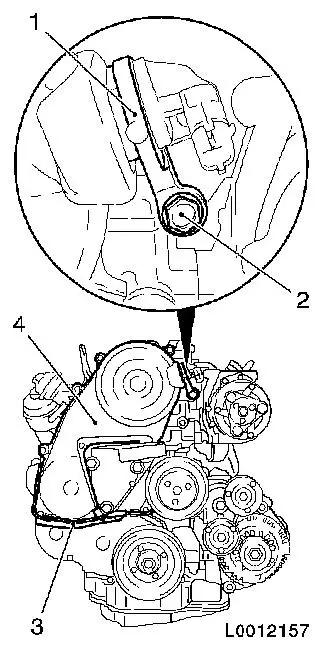

| 31. |

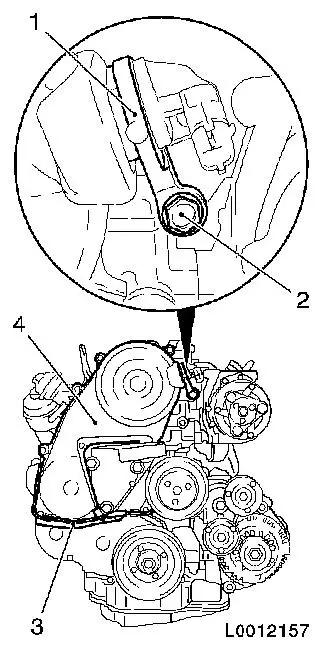

Detach front toothed belt cover (top) (4)

| • |

Unscrew 8x bolts

Note: Note different

bolt lengths

|

| • |

Remove camshaft sensor bracket (1)

|

|

|

|

| 32. |

Remove engine damping block support

| • |

Detach from engine damping block bracket

|

| • |

Detach from cylinder block

|

| • |

Remove engine damping block adapter (1)

|

|

|

|

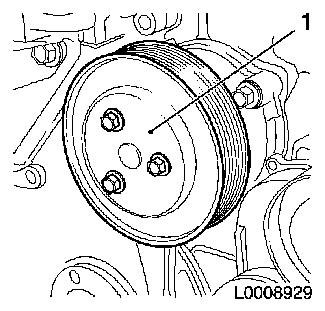

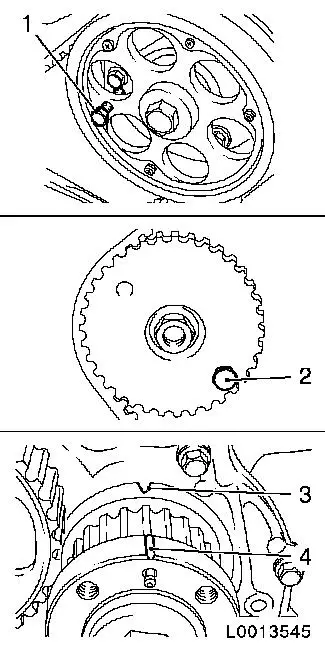

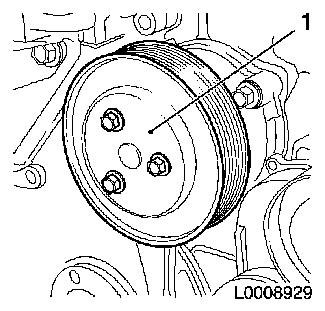

| 33. |

Remove coolant pump drive gear (1)

|

|

|

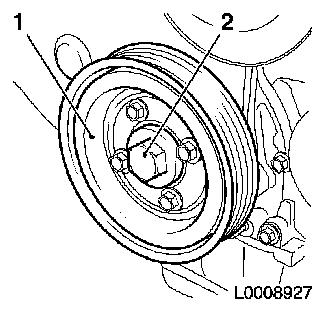

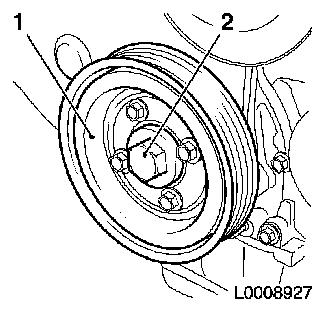

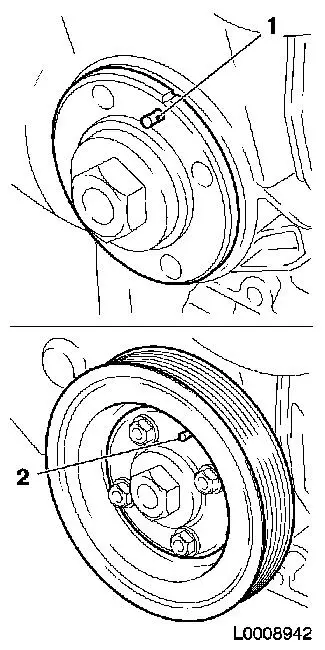

| 34. |

Detach torsional vibration damper (1)

| • |

Unscrew 4x bolts

Note: Counterhold at

bolt (2)

|

|

|

|

| 35. |

Remove front toothed belt cover (lower) (1)

|

|

|

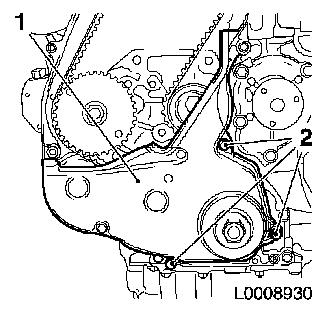

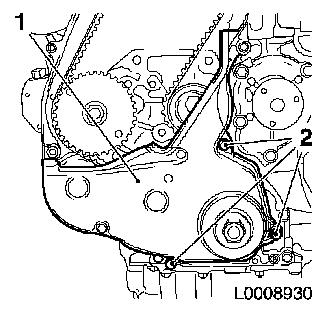

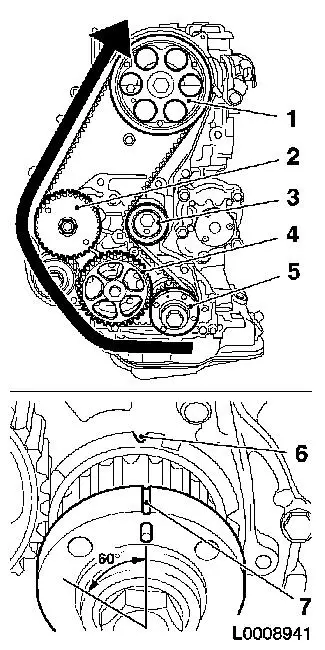

| 36. |

Move crankshaft in direction of engine rotation to "Cylinder

no.1 combustion stroke TDC"

Note: Marking on

toothed belt drive gear must align with projection on oil pump

cover (arrows)

| • |

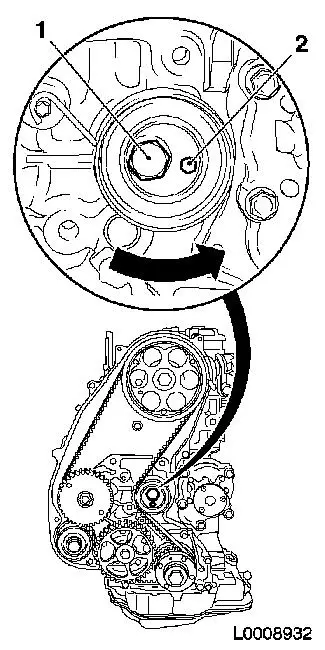

Fix with TDC fixing bolt (M6) (1) camshaft drive gear

|

| • |

Fix with TDC fixing bolt (M8) (2) high pressure pump gear

|

|

|

|

| 37. |

Remove toothed belt

| • |

Mark direction of rotation

|

| • |

Slacken the toothed belt tension roller

|

| • |

Apply preliminary tension to toothed belt tension roller with

hexagon (2) in direction of arrow

|

| • |

Fix toothed belt tension roller in pre-tensioned position

|

|

|

|

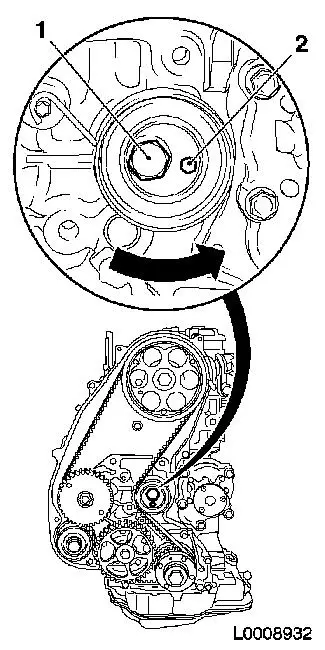

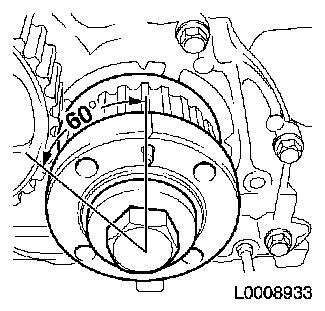

| 38. |

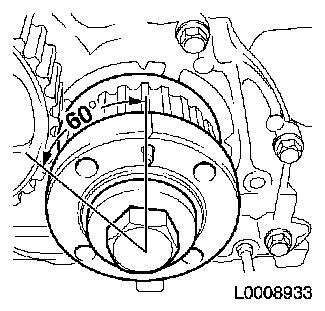

Turn crankshaft 60° against the direction of engine

rotation

|

|

|

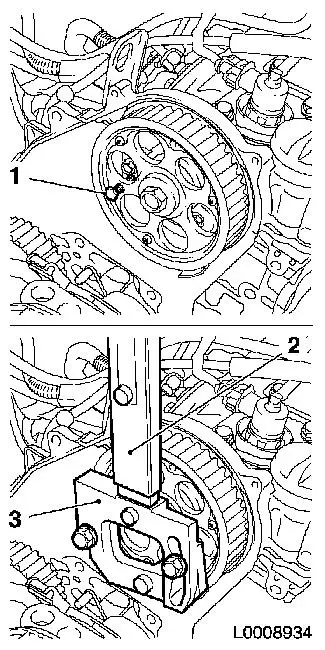

| 39. |

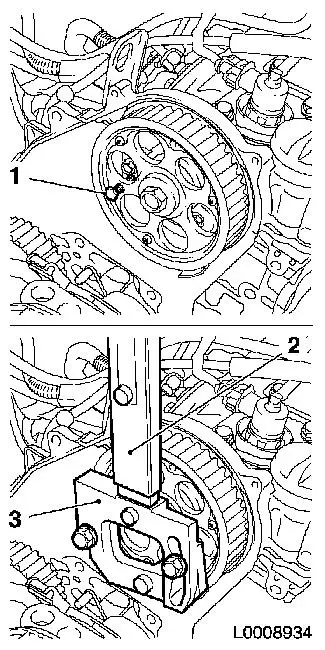

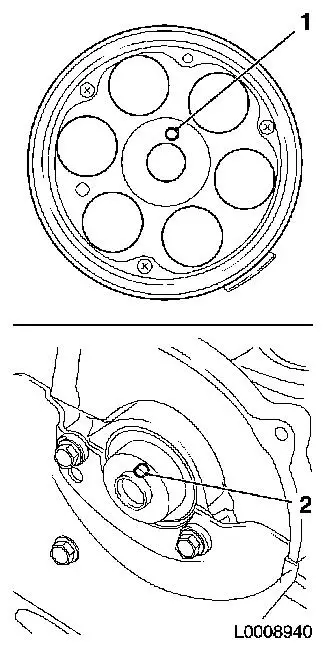

Remove camshaft sprocket

| • |

Remove TDC fixing bolt (1)

|

| • |

Unscrew bolt

Note: Counterhold with

KM-6347 (2) in conjunction with KM-956-1 (3)

|

|

|

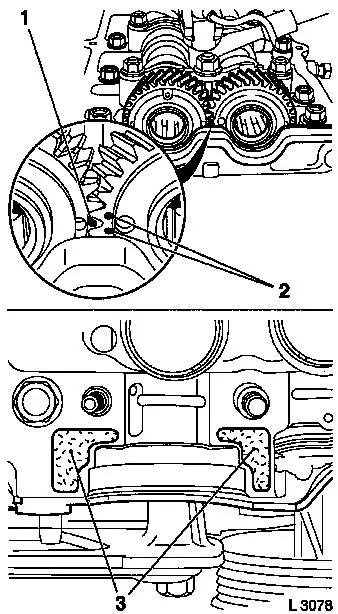

|

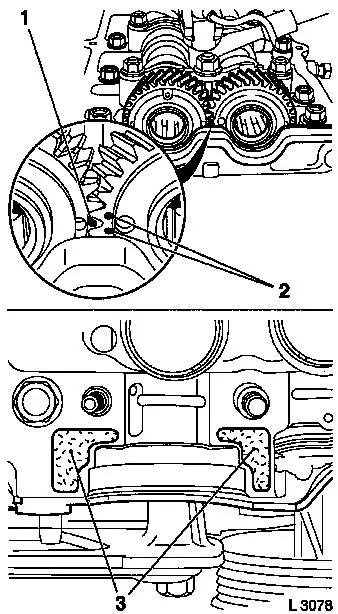

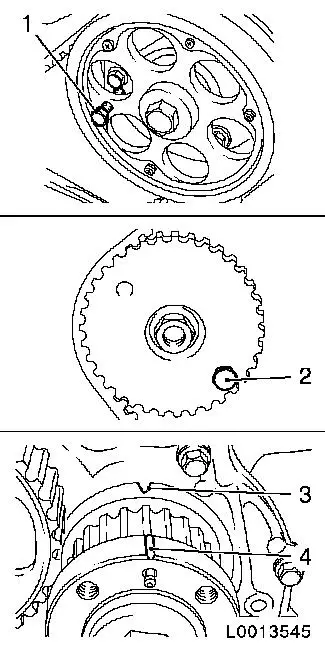

| 40. |

Lock exhaust camshaft gear wheels

| • |

Remove camshaft bearing cap (3)

|

| • |

Lock balancer gear wheel, exhaust camshaft (2), with exhaust

camshaft gear wheel (4) with KM-6092-10

(1) so that it cannot twist

|

|

|

|

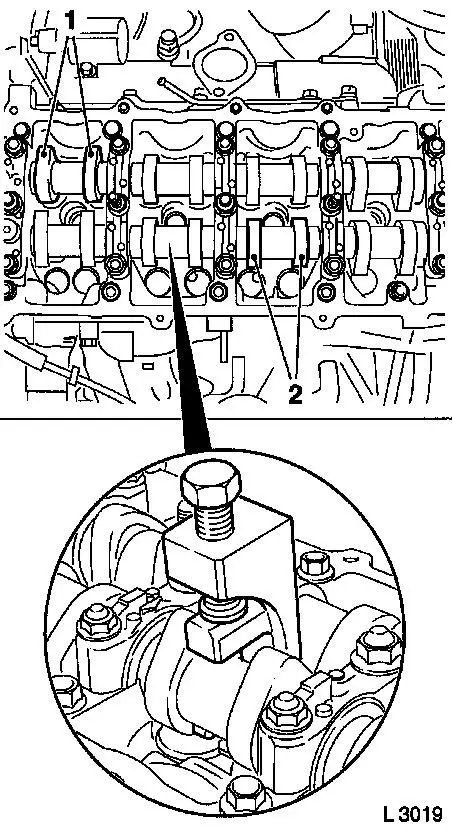

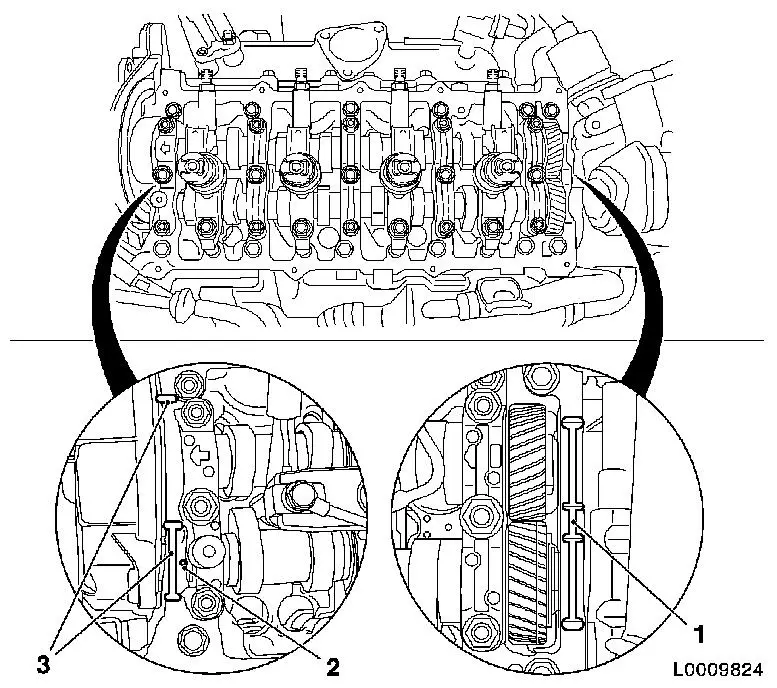

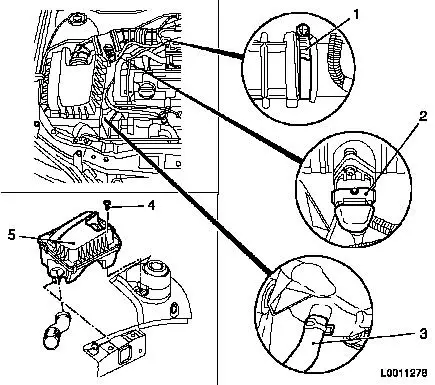

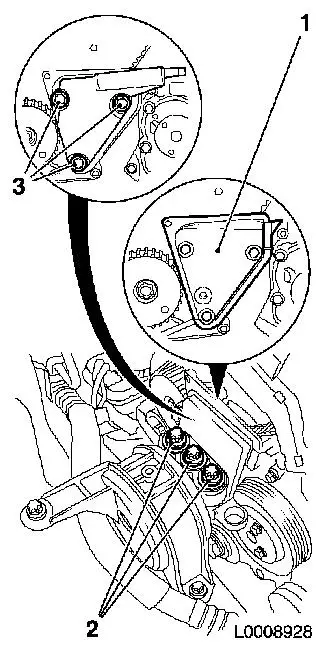

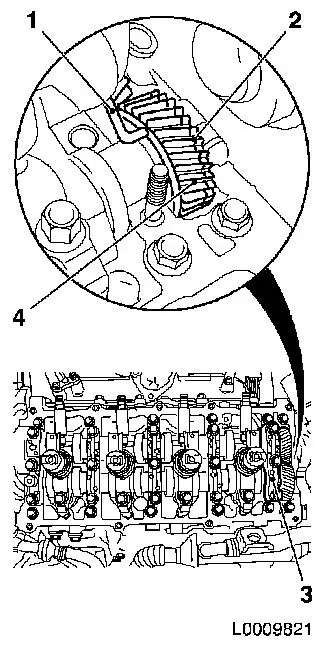

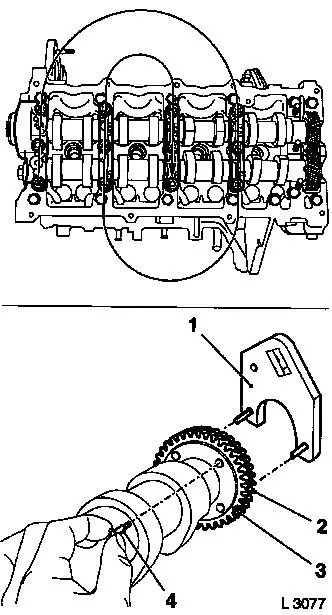

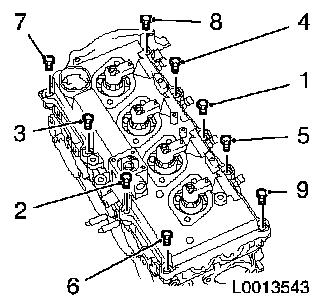

| 41. |

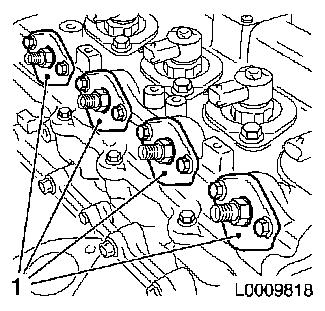

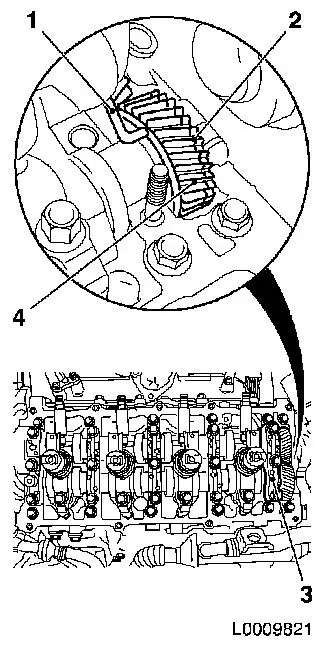

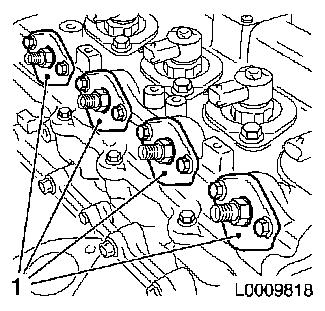

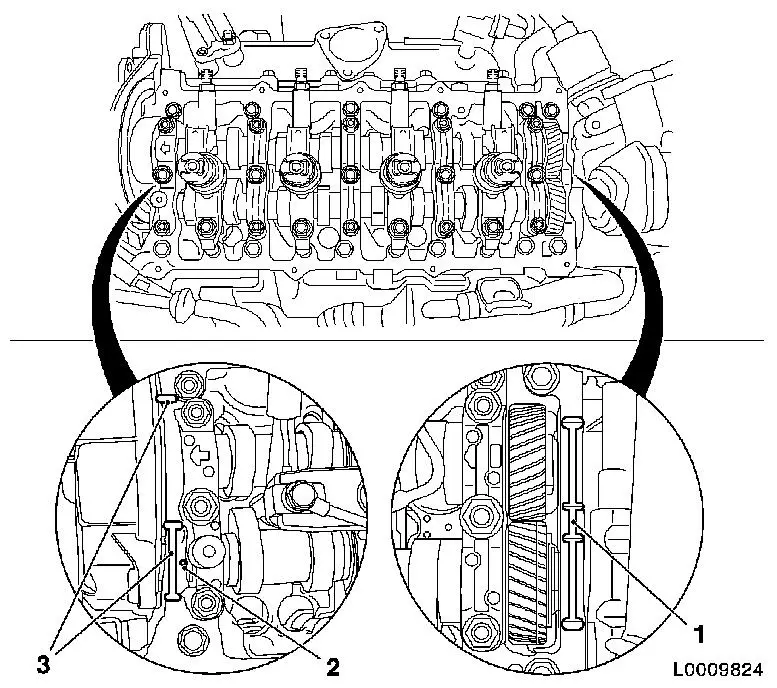

Remove both camshafts

Note: Note marking

before dismantling camshaft bearing cap

| • |

Release the camshaft bearing cap in the order illustrated in a

spiral in stages of 1/2 to 1 turn

Note: When replacing

the exhaust camshaft, the balancer gear wheel (2) must be

pre-tensioned with KM-6092 (1) and

connected to the gear wheel of the exhaust camshaft (3) with fixing

pin KM-6092-10 (4)

|

|

|

|

| 42. |

Remove camshaft seal ring (1)

|

|

|

Install

Install

| 43. |

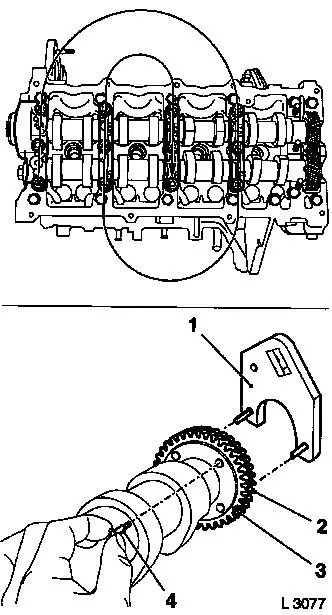

Pre-tension camshaft gearing

|

| 44. |

Insert both camshafts

Important: When installing the

camshafts, care must be taken to ensure that the marking (1)

exhaust camshaft gear wheel is positioned between the two markings

(2) gear wheel intake camshaft and the markings are approximately

level with the upper edge of the camshaft housing

|

| • |

Insert camshafts into camshaft housing

|

| • |

Apply surface sealant (green) to sealing surfaces (3) of the

1st camshaft bearing cap

|

|

|

|

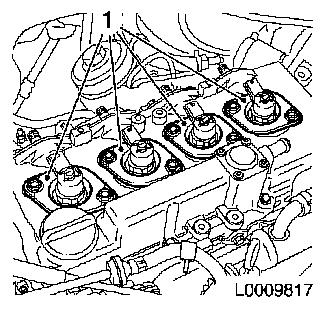

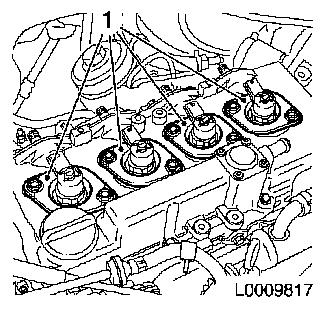

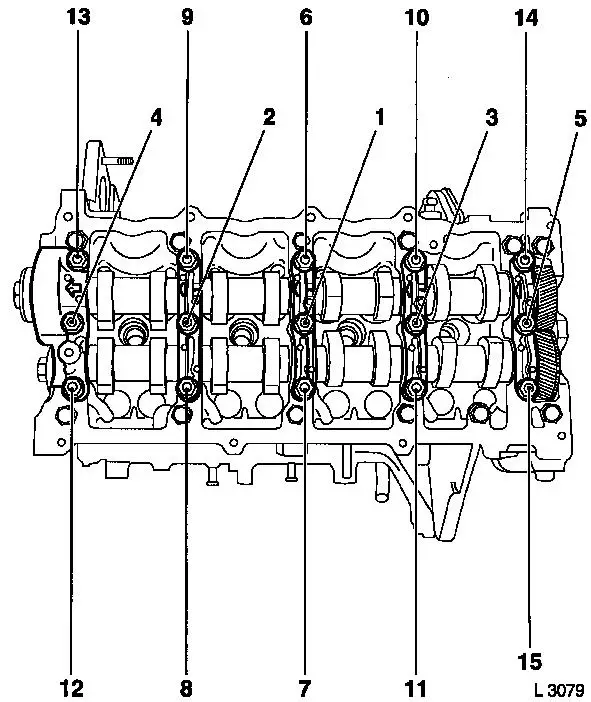

| 45. |

Install both camshafts

Note: Coat bearing

positions with engine oil

| • |

Attach camshaft bearing cap 1 - 4 to camshaft housing

Note: Arrows on bearing

cap point towards engine timing side

|

| • |

Remove KM-6092-10 from gearwheel

exhaust camshaft and attach camshaft bearing cap 5

|

| • |

Tighten the camshaft bearing cap in the order illustrated (1) -

(15) in stages of 1/2 to 1 turn

| – |

Tighten 10x nut (M8) 21.6 Nm

|

| – |

Tighten 5x bolt (M10) 26.5 Nm

|

|

|

|

|

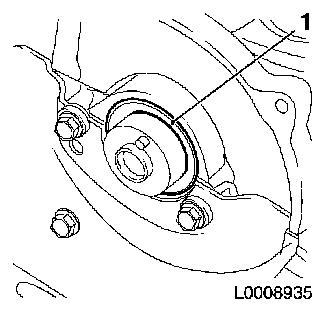

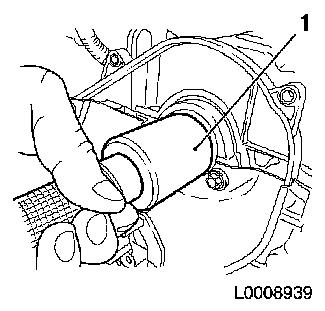

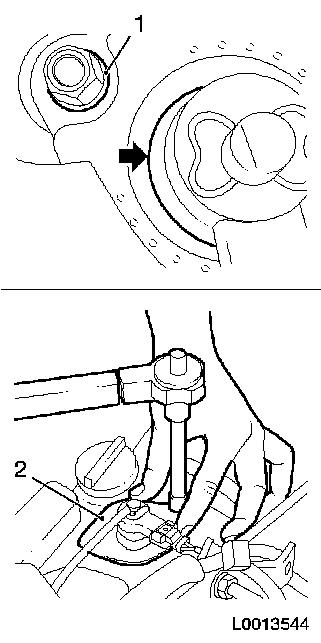

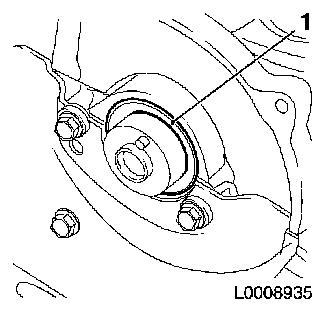

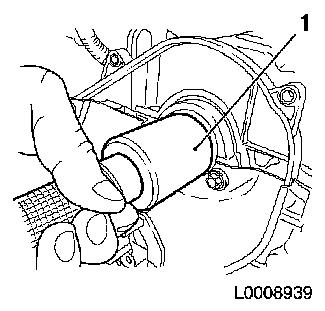

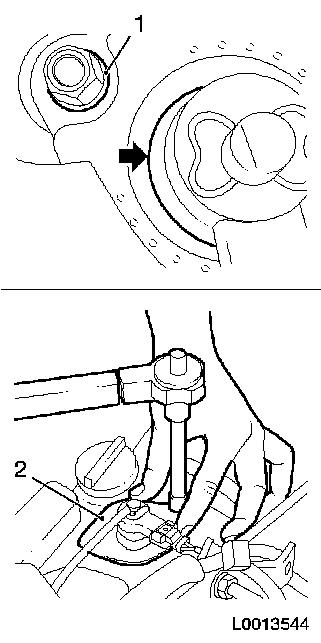

| 46. |

Insert camshaft seal ring

| • |

Drive in flush using KM-656 (1)

|

|

|

|

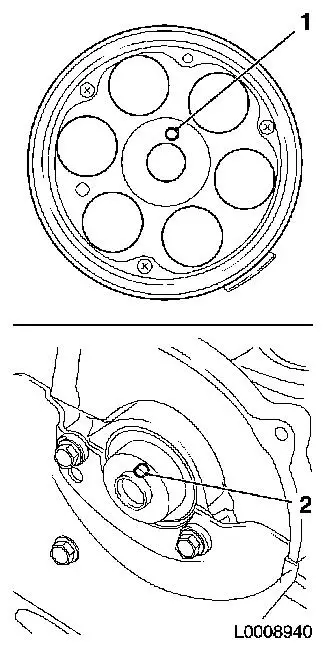

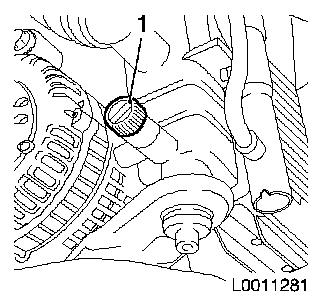

| 47. |

Install camshaft sprocket

Note: Camshaft journal

(2) must engage in the bore (1) in the camshaft sprocket

| • |

Tighten bolt 63.7 Nm

Note: Counterhold with

KM-6347 in conjunction with KM-956-1

|

| • |

Screw in TDC fixing bolt

|

|

|

|

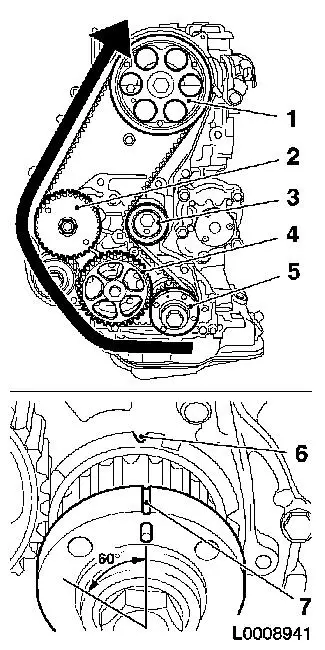

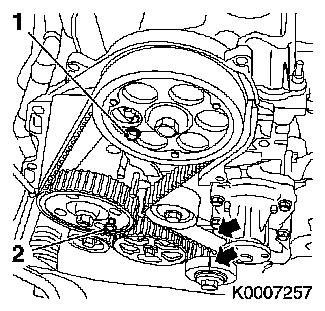

| 48. |

Install toothed belt

Note: TDC fixing bolts

must be installed in the high pressure drive gear and camshaft

drive gear and markings (6) and (7) must align

| • |

Position toothed belt

| – |

Toothed belt must be tensioned in the direction of the arrow

from the toothed belt drive gear (5) via the oil pump drive gear

(4) and high pressure pump drive gear (2) to the camshaft sprocket

(1)

|

| – |

Observe direction of rotation

|

|

| • |

Slacken the toothed belt tension roller (3)

|

| • |

Remove 2x TDC fixing bolt

|

| • |

Turn crankshaft 60° against the direction of engine

rotation

|

| • |

Tighten toothed belt tension roller 38.2 Nm

|

|

|

|

| 49. |

Timing, Check

| • |

Turn crankshaft 6 revolutions in direction of engine rotation

to the adjustment position

|

| • |

The following factors must be present at the adjustment

position

Note: If one of these

factors is not present, the timing must be adjusted

| 1. |

TDC fixing bolt M6 (1) must be able to be inserted

in the camshaft drive gear |

| 2. |

TDC fixing bolt M8 (2) must be able to be inserted

in the high pressure pump drive gear |

| 3. |

Marking (4) on the toothed belt drive gear must

align with the marking (3) on the oil pump housing cover |

|

| • |

Remove 2x TDC fixing bolt

|

|

|

|

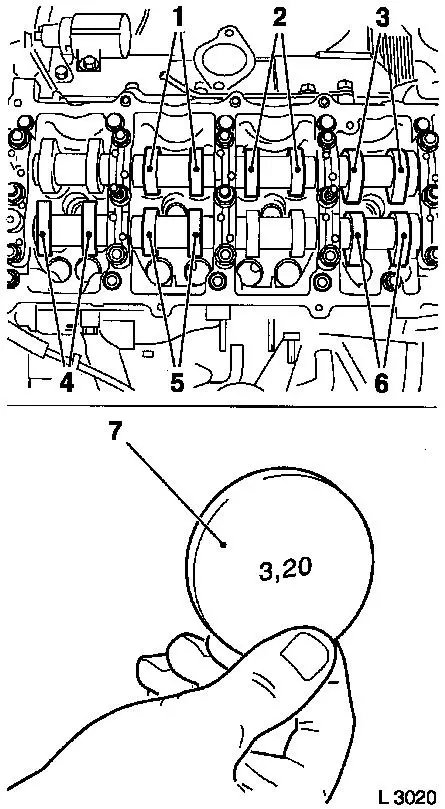

| 50. |

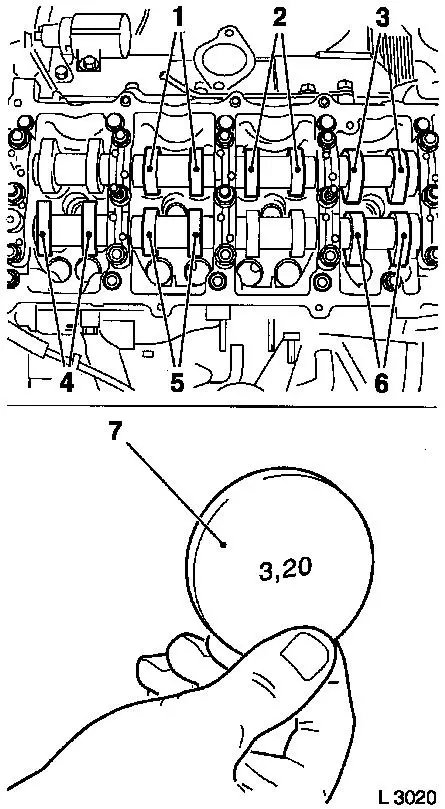

Turn the crankshaft until the cam pair (1) and (2) faces

upwards.

|

| 51. |

Check valve lash with feeler gauge

Note: Valve lash must

be checked at room temperature when the engine is cold.

| • |

Test values: Intake valve/exhaust valve (0.35 - 0.45 mm)

|

|

| 52. |

Adjust valve play

| • |

Turn the bucket tappet until the tappet groove faces

outwards

|

Important: Care should be taken

that the valves do not strike the piston head

|

| • |

Press down cup tappet with KM-6090

Note: Note different

tool designs for intake and exhaust valve

| – |

Marking - IN = intake side

|

| – |

Marking - EX = exhaust side

|

|

|

|

|

| 53. |

Example for determination of shim thickness:

|

1.

|

Thickness of installed shim

|

|

3.15 mm

|

|

2.

|

Measurement between cams and cup tappets

|

+

|

0.45 mm

|

|

|

|

=

|

3.60 mm

|

|

3.

|

Nominal valve play

|

-

|

0.40 mm

|

|

4.

|

Thickness of new shim

|

=

|

3.20 mm

|

|

| 54. |

Insert shim

| • |

Coat new shim (7) with engine oil and insert in cup tappet with

code facing down

|

|

| 55. |

Check and adjust remaining valves

| • |

Turn crankshaft 180° in the direction of rotation of the

engine

| – |

Check and adjust valve pair (6) and (2)

|

|

| • |

Turn crankshaft 180° in the direction of rotation of the

engine

| – |

Check and adjust valve pair (5) and (3)

|

|

| • |

Turn crankshaft 180° in the direction of rotation of the

engine

| – |

Check and adjust valve pair (4) and (1)

Note: Valve lash must

be checked again on all adjusted valves

|

|

|

|

|

| 56. |

Install front toothed belt cover (lower)

|

Important: Journal (1) of toothed

belt drive gear must engage in the bore (2) of the torsional

vibration damper

|

| 57. |

Install torsional vibration damper

| • |

Tighten 4x bolt 19.6 Nm

Note: Counterhold

against bolt, toothed belt drive gear

|

|

|

|

| 58. |

Install coolant pump drive gear

| • |

Tighten 3x bolt 12.3 Nm

|

|

| 59. |

Install engine damping block bracket

| • |

Insert engine damping block adapter

|

| • |

Attach engine damping block support to cylinder block

|

| • |

Engine damping block support to engine damping block

bracket

|

|

| 60. |

Install front toothed belt cover (top)

| • |

Tighten 8x bolt 9.8 Nm

Note: Note different

bolt lengths

|

| • |

Install camshaft sensor bracket

|

| • |

Attach vacuum line to toothed belt cover

|

|

| 61. |

Attach wiring trough to front toothed belt cover (top)

| • |

Attach wiring harness

| – |

Connect camshaft sensor wiring harness plug

|

|

|

| 62. |

Insert ribbed V-belt

Note: Note running

direction of ribbed V-belt

| • |

Position ribbed V-belt

| – |

I. Ribbed V-belt without air conditioning

|

| – |

II. Ribbed V-belt with air conditioning

|

|

| • |

Apply tension to ribbed V-belt tensioner via bolt (1) in the

direction of the arrow

|

| • |

Release ribbed V-belt tensioner

|

|

|

|

| 63. |

Raise vehicle by its full height

|

| 64. |

Remove engine mount KM-6173

|

| 65. |

Remove engine mount KM-6001-A

|

| 66. |

Install lower engine cover and right engine splash guard

|

| 67. |

Lower vehicle by its full height

|

| 68. |

Detach pressure chamber

| • |

Unscrew 2x bolts 1 - 1 1/2 turns

|

|

| 69. |

Replace injector gaskets

|

|

|

| 70. |

Install 4x injector

| • |

Install 4x brackets

| – |

Align injectors with EN-48560 (1)

|

|

|

|

|

| 71. |

Fasten 4x high pressure lines for pressure chamber to

injector

| • |

Fit 8x union nuts finger-tight

|

|

| 72. |

Fasten 4x injectors

| • |

Tighten 4x bolt in three stages

|

|

|

|

| 73. |

Fasten pressure chamber

|

| 74. |

Detach 4x high-pressure lines from pressure chamber to

injector

| • |

Seal off connections on pressure chamber with suitable sealing

plugs

|

| • |

Seal injector connections with protective caps

|

|

| 75. |

Clean sealing surfaces.

|

|

| 76. |

Apply sealing compound

Important: Oil return bore (2)

may not be covered with adhesive sealing compound

|

| • |

Apply adhesive sealing compound (white) to sealing surfaces (1)

and (3)

|

|

|

| 77. |

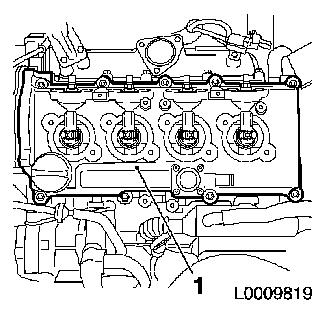

Install camshaft housing cover

| • |

Tighten 9x bolt in the stated order (1...9) 9.8 Nm

|

|

|

|

| 78. |

Install 4x new seal, injectors (2)

| • |

Align seal for injectors

Note: Sealing lip of

seal must be in full contact with the injector with no gaps

(arrow)

|

| • |

Coat 8x bolt head contact surface (1) with special grease

(white)

|

| • |

Tighten injector seal in 2 stages

Note: During the

tightening process, press injector seal against the camshaft

housing cover with your hand

| 1. |

Tighten 2x bolt 10

Nm |

| 2. |

Tighten 2x bolt 19

Nm |

|

|

|

|

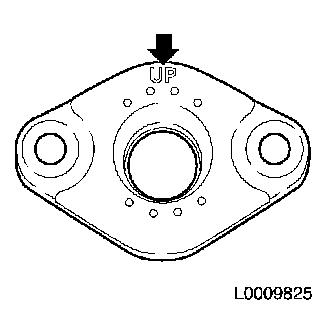

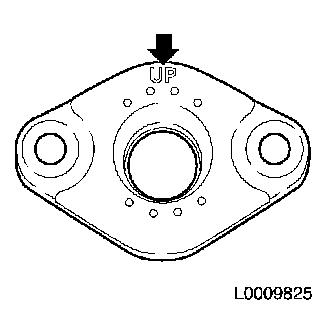

| 79. |

Install 4x new seal, connection for injectors

Note: Marking "UP" must

point upwards

|

|

|

| 80. |

Install bracket, oil dipstick guide tube

| • |

Attach bracket, oil dipstick guide tube, to camshaft

housing

|

| • |

Attach dipstick guide tube

|

|

| 81. |

Install rear left engine transport shackle

|

| 82. |

Install rear right engine transport shackle

|

| 83. |

Install fuel return line

Note: Note different

bolt lengths

| • |

Attach 4x fuel return line to injector

|

| • |

Attach fuel return line to accumulator

|

|

| 84. |

Install 4x high-pressure lines

| • |

Tighten 8x union nut with KM-812 or

KM-6098 25

Nm

Note: Tighten union

nuts first at injectors, then at pressure chamber

|

|

| 85. |

Attach wiring harness for injectors

| • |

Connect 4x wiring harness plugs, glow plug

|

| • |

Connect 4x injector wiring harness plug

|

|

| 87. |

Install air intake pipe.

|

| 88. |

Install air cleaner housing with air intake hose

| • |

Attach water drain hose to air cleaner housing

|

| • |

Attach air intake hose to air intake pipe

|

| • |

Connect wiring harness plug to air mass flow meter

|

|

| 89. |

Install engine cover

| • |

Detach oil filler port closure cap

|

| • |

Attach oil filler port closure cap

|

|

| 90. |

Connect battery

| • |

Attach earth connection to earth terminal

|

|

Important: Wear protective

goggles

|

| 91. |

Carry out leak test on high pressure system

Note: Engine must be at

operating temperature

| • |

Carry out actuator test (fuel leak)

|

| • |

Visual inspection of high pressure system for fuel leak

|

|

| 92. |

Cooling System, Charge and Bleed

|

| 93. |

Program volatile memories

|

1 ) Protective caps are available from the Opel

parts catalogue under catalogue number 45 06 154 / part number:

9201697

|