|

Adjust balancer shaft unit/crankshaft tooth

backlash

Remove Remove

| 1. |

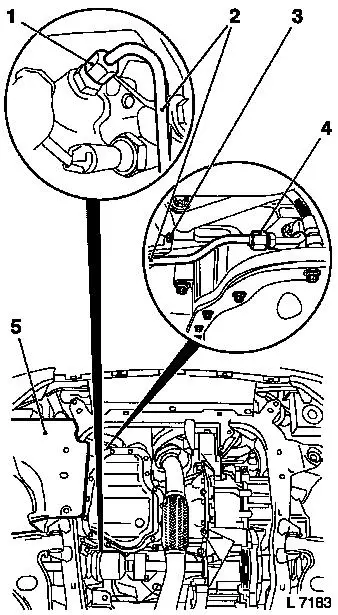

Remove lower engine splash guard

|

| 2. |

Disconnect catalytic converter control oxygen sensor wiring

harness plug

|

| 3. |

Remove front exhaust pipe

|

| 4. |

Remove oil drain bolt

Note: Collect engine

oil

|

| 5. |

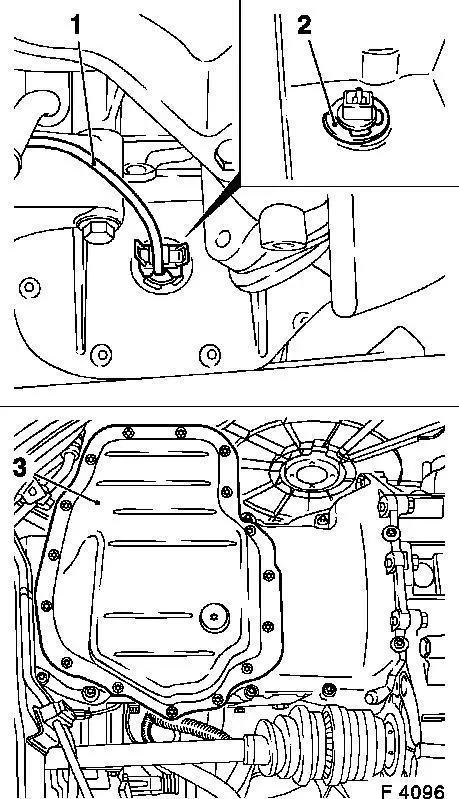

Disconnect wiring harness plug (1) for dynamic oil level

control and remove retaining ring (2)

|

| 6. |

Detach lower part of oil pan (3) from upper part of oil pan

|

|

|

| 7. |

Clean sealing surfaces and remove gasket remnants.

|

| 8. |

Remove oil filter from oil pump with KM-726-A

|

| 9. |

Detach union nut (4) from turbocharger oil feed line

(turbocharger)

Note: Place collecting

basin underneath.

|

| 10. |

Detach bracket (3) from cylinder block

|

| 11. |

Detach union nut (1) from cylinder block flange and remove

turbocharger oil feed line (cylinder block) (2)

|

|

|

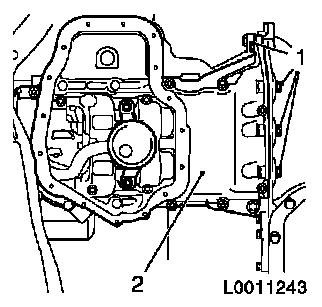

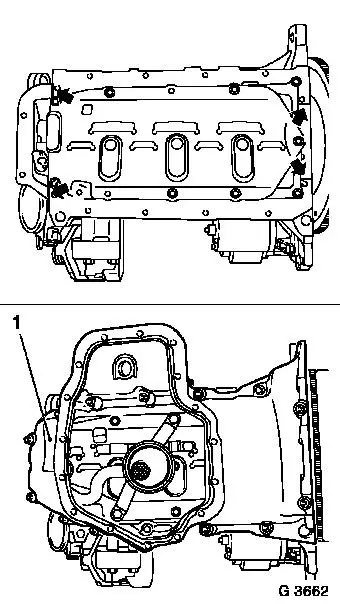

| 12. |

Detach oil pan top bolts (1) from transmission housing

|

| 13. |

Detach upper part of oil pan (2) from cylinder block and remove

oil pump

|

|

|

| 14. |

Detach 2x oil intake pipe bolts (1) from balancer shaft

unit

|

|

|

| 15. |

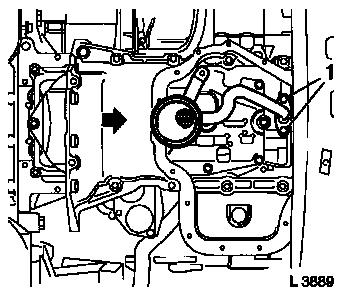

Move upper part of oil pan in direction of arrow and detach 2x

oil intake pipe bolts (1) from oil pump

|

| 16. |

Remove upper part of oil pan with oil intake pipe

|

|

|

| 17. |

Clean sealing surfaces and remove gasket remnants.

|

| 18. |

Detach oil baffle plate from balancer shaft unit.

|

Important: Only one balancer

piece may be installed

|

| 19. |

Detach balancer shaft unit from cylinder block and crankshaft

bearing cap and remove with balancer piece. For better allocation,

a number (identification) is located on the balancer piece. The

tooth backlash can also be adjusted using balancer pieces of

varying thickness.

|

Identification

|

Thickness of balancer piece in mm

|

|

55

|

0.535 to 0.565

|

|

58

|

0.565 to 0.595

|

|

61

|

0.595 to 0.625

|

|

64

|

0.625 to 0.655

|

|

67

|

0.655 to 0.685

|

|

70

|

0.685 to 0.715

|

|

73

|

0.715 to 0.745

|

|

76

|

0.745 to 0.775

|

|

79

|

0.775 to 0.805

|

|

82

|

0.805 to 0.835

|

|

85

|

0.835 to 0.865

|

Note: The next larger or

smaller balancer piece changes the tooth backlash by approx. 0.02

mm!

Example for selecting the balancer piece: with an installed

balancer piece with the mark "70" a tooth backlash of 0.08 mm was

determined. If a balancer piece with the mark "67" is then

installed, then this produces a tooth backlash of approx. 0.06

mm.

.

|

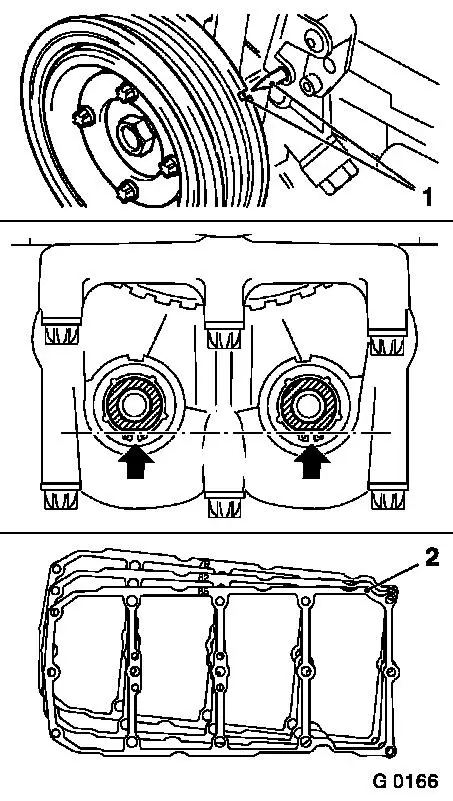

| 20. |

Turn the crankshaft in the direction of engine rotation to "1st

Cylinder TDC" (mark 1) using the fastening bolt for the toothed

belt drive gear.

|

| 21. |

Turn balancer shafts so that both flattened sides (arrows)

point downward and form a horizontal line.

|

| 22. |

Attach selected balancer piece (2) with balancer shaft unit to

cylinder block and crankshaft bearing cap

| • |

Tighten all bolts uniformly 20 Nm +

45°

|

|

|

|

| 23. |

Following installation of balancer shaft unit, tooth backlash

must be re-checked and, if necessary, adjusted.

Note: If the balancer

shaft unit needs to be replaced, use the thickest balancer piece

(identification "85") for the initial installation to ensure a

tooth backlash in any case.

|

Install

Install

| 24. |

Attach oil baffle plate to balancer shaft unit 8 Nm

|

| 25. |

Apply a bead of adhesive sealing compound (black) to joints

(arrows) of oil pump and rear crankshaft bearing cap

|

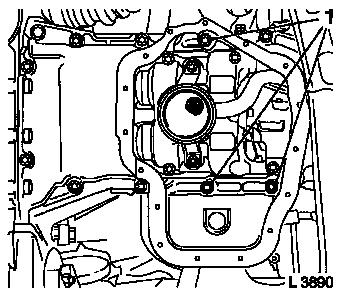

| 26. |

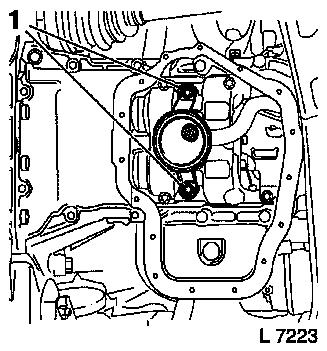

Insert upper part of oil pan (1) with new gasket and oil intake

pipe

|

| 27. |

Attach oil intake pipe to oil pump with new seal ring 8 Nm

1)

|

| 28. |

Attach oil intake pipe to balancer shaft unit 10 Nm

|

|

|

| 29. |

Attach upper part of oil pan to cylinder block, oil pump and

transmission housing with new gasket

|

| 30. |

Insert contact surfaces of bolts (1) coated with surface

sealant (green)

Installation sequence:

| 1. |

Tighten all bolts loosely. |

| 2. |

Tighten bolts at cylinder block and oil pump 20 Nm |

| 3. |

Tighten bolts at transmission housing 40 Nm . |

|

|

|

| 31. |

Insert turbocharger oil feed line (cylinder block) and attach

to cylinder block flange with union nut 20

Nm

|

| 32. |

Attach turbocharger oil feed line union nut (cylinder block) to

turbocharger oil feed line (turbocharger) 20 Nm

|

| 33. |

Attach turbocharger oil feed line bracket to cylinder block

35 Nm

|

| 34. |

Coat oil filter seal ring with a thin layer of engine oil and

attach to oil pump 15 Nm

|

| 35. |

Insert dynamic oil level control plug-in connection into upper

section of oil pan with new seal ring and fix in position with

retaining ring

|

| 36. |

Attach lower section of oil pan to upper section of oil pan

with new gasket and new bolts 8 Nm +

30°

|

| 37. |

Attach oil drain bolt to lower section of oil pan with new

gasket 10 Nm

|

| 38. |

Connect wiring harness plug for dynamic oil level control

|

| 39. |

Install front exhaust pipe with new gasket 35 Nm

|

| 40. |

Connect wiring harness plug for catalytic converter control

oxygen sensor

|

| 41. |

Route wiring harness

Note: Note routing of

wires

|

| 42. |

Install lower engine splash guard

|

| 43. |

Top up engine oil quantity to "MAX" mark on oil dipstick

|

1 ) Recut thread before use and insert bolts with

bolt locking compound (red). Installation time including torque

check should not exceed 10 minutes.

|