|

Valve Lash - Petrol Engine, Check and Adjust

Remove Remove

| 2. |

Disconnect battery

| • |

Detach earth connection from earth terminal

|

|

| 3. |

Remove air cleaner housing

- A 16 XER, Z 16 XER

- A 18 XER, Z 18 XER

|

| 4. |

Remove front toothed belt cover (top)

|

| 5. |

Remove cylinder head cover

|

| 6. |

Raise vehicle by its full height

|

| 7. |

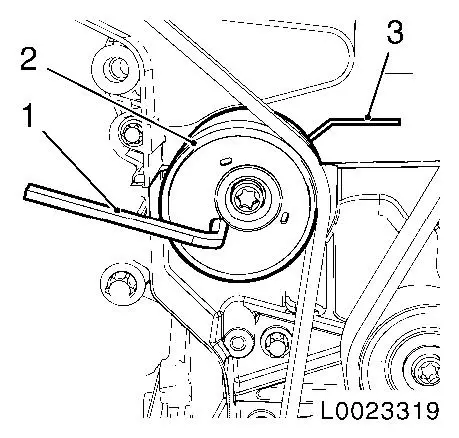

Remove ribbed V-belt tensioner

|

| 8. |

Set engine to TDC

| • |

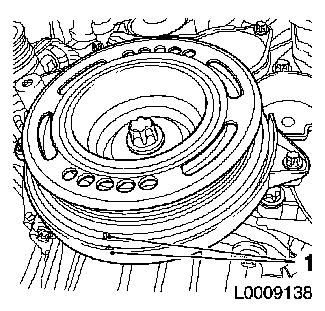

Turn crankshaft in the direction of engine rotation by the bolt

of the torsional vibration damper to cylinder 1 TDC of combustion

stroke

|

| • |

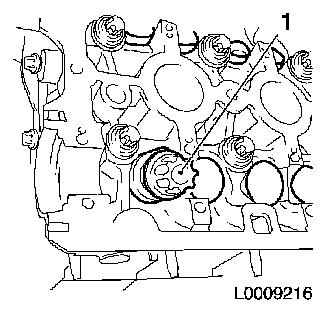

Marking on torsional vibration damper must align with the

marking on the lower part of the toothed belt cover (1)

|

|

|

|

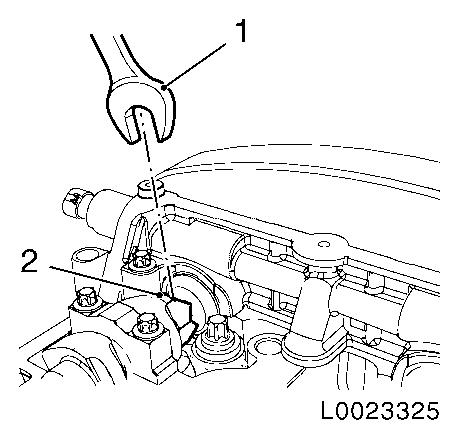

| 9. |

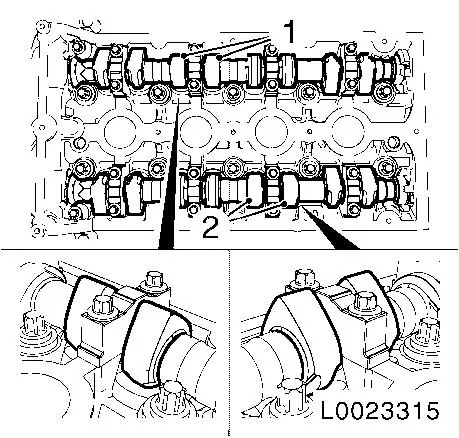

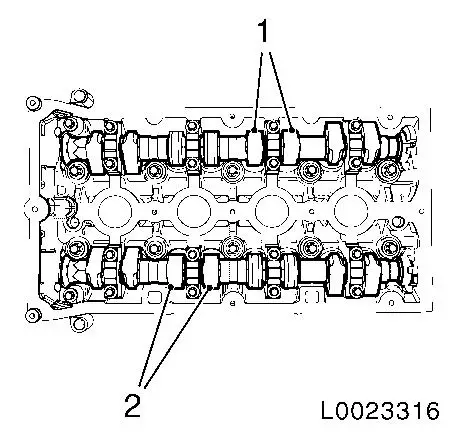

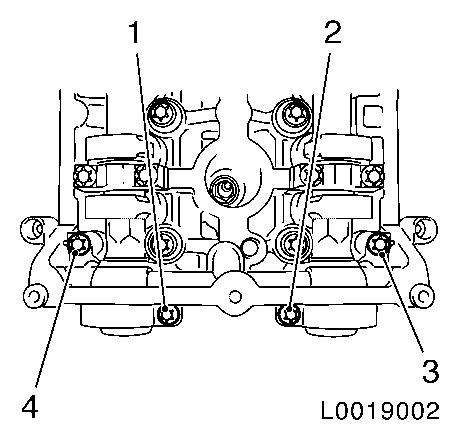

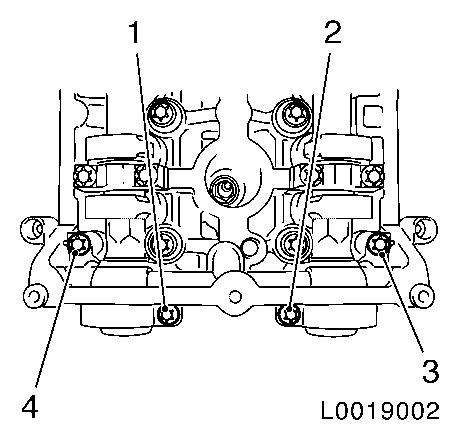

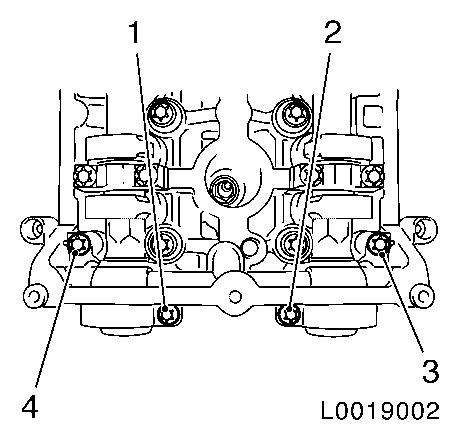

Cams at the intake side of cylinder no.2 (1) and the exhaust

side of cylinder no.3 (2) are on top and tilted slightly towards

the inside to the same extent

|

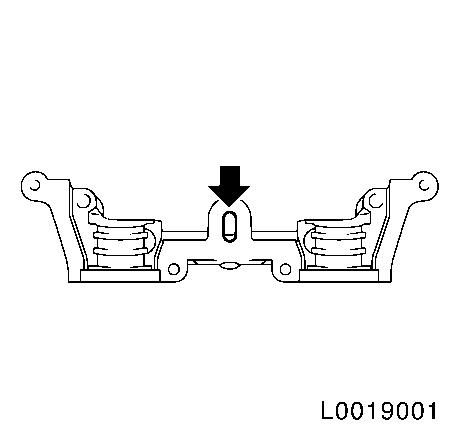

|

|

| 10. |

Check valve lash

| • |

Prescribed valve lash

| – |

Intake valves 0.21 - 0.29 mm

(nominal value 0.25 mm )

|

| – |

Exhaust valves 0.27 - 0.35 mm

(nominal value 0.30 mm )

|

|

|

| 11. |

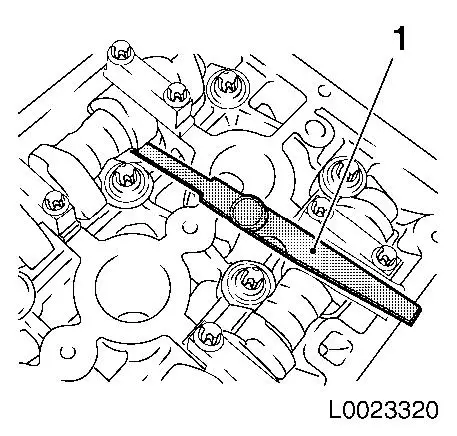

Check 4x valve clearance

| • |

Check valve lash with KM-6361 (1)

|

|

|

|

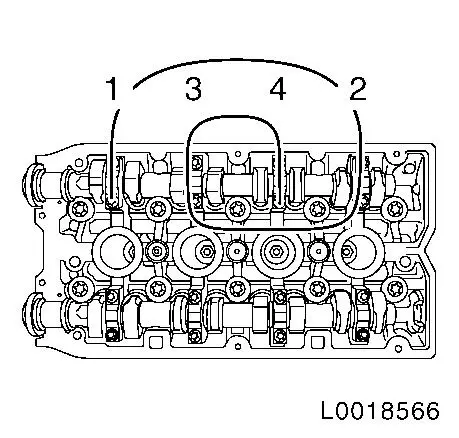

| 12. |

Rotate crankshaft on torsional vibration damper bolt by

180°

| • |

In direction of engine rotation.

| – |

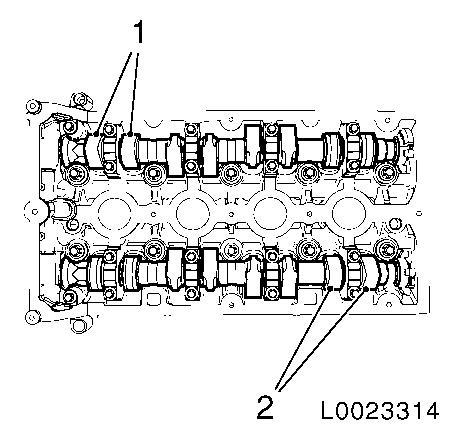

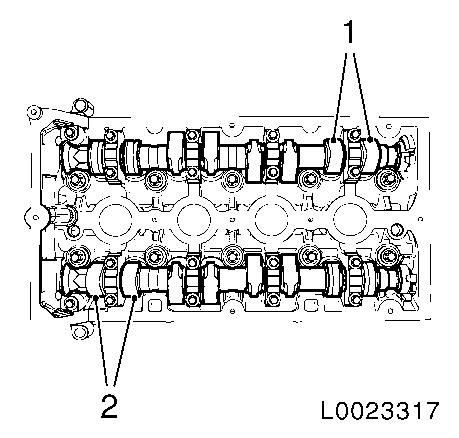

Pairs of cams (1) and (2) point upwards at an angle

|

|

|

|

|

| 13. |

Check 4x valve clearance

| • |

Check valve lash with KM-6361

|

|

| 14. |

Rotate crankshaft on torsional vibration damper bolt by

180°

| • |

In direction of engine rotation.

| – |

Pairs of cams (1) and (2) point upwards at an angle

|

|

|

|

|

| 15. |

Check 4x valve clearance

| • |

Check valve lash with KM-6361

|

|

| 16. |

Rotate crankshaft on torsional vibration damper bolt by

180°

| • |

In direction of engine rotation.

| – |

Pairs of cams (1) and (2) point upwards at an angle

|

|

|

|

|

| 17. |

Check 4x valve clearance

| • |

Check valve lash with KM-6361

|

|

| 18. |

Rotate crankshaft on torsional vibration damper bolt by

180°, to TDC of combustion stroke of cylinder 1

|

| 19. |

Raise vehicle by its full height

|

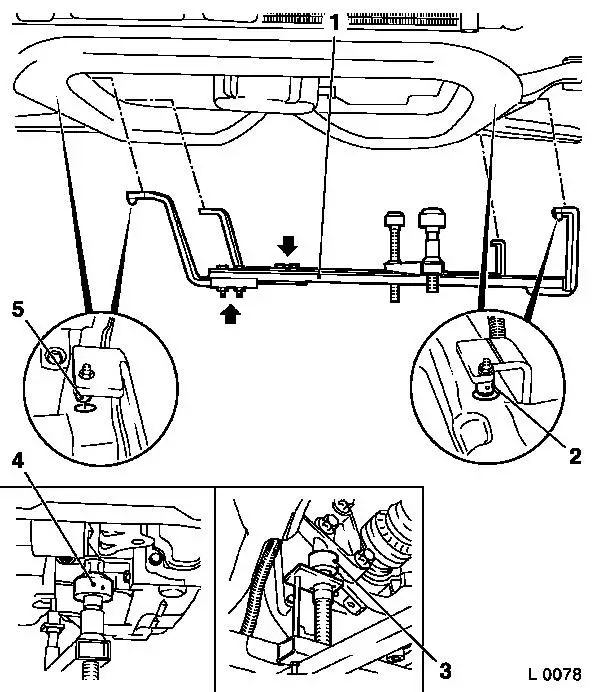

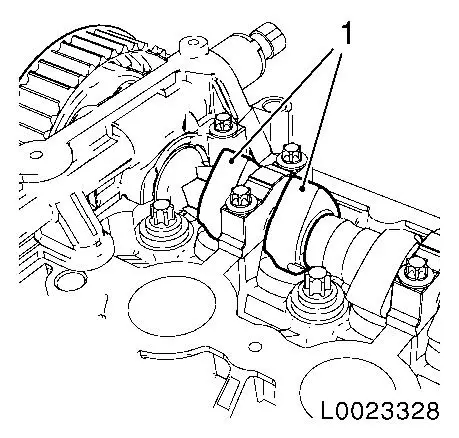

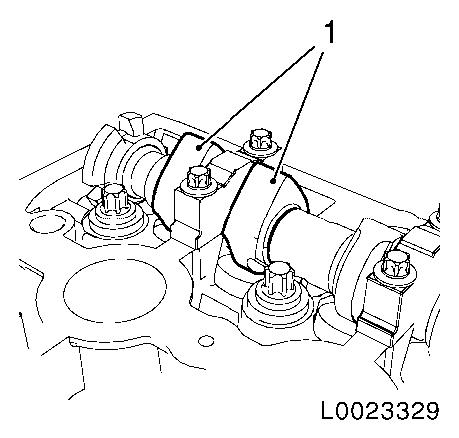

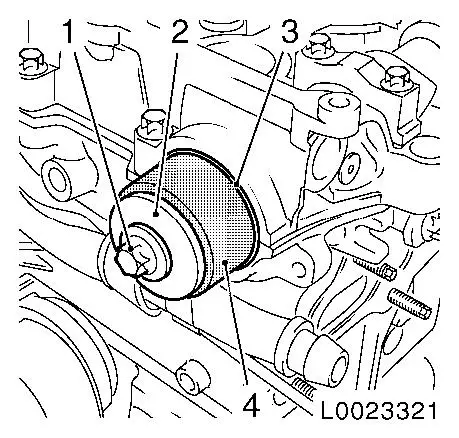

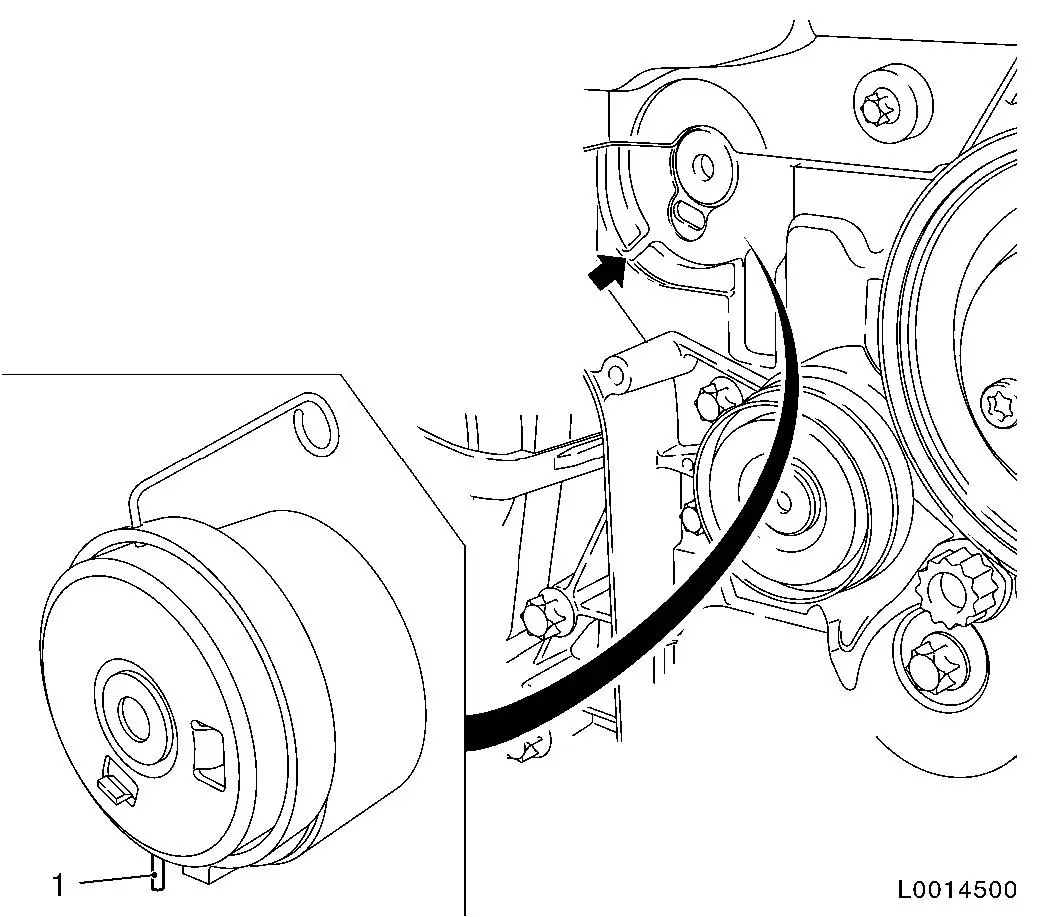

| 20. |

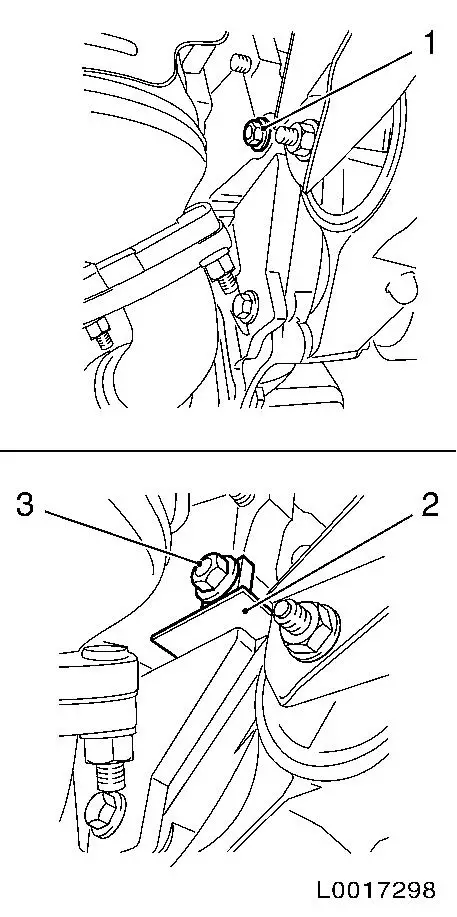

Immobilise crankshaft via starter ring

| • |

Attach KM-6625

| – |

Detach screwed connection (1)

|

| – |

Tighten screwed connection (3)

|

|

|

|

|

| 21. |

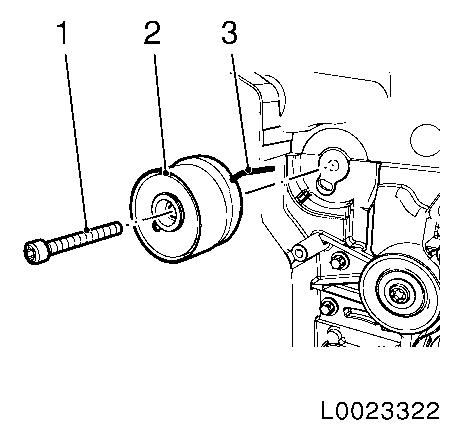

Remove torsional vibration damper

|

| 22. |

Remove front toothed belt cover (bottom)

|

| 23. |

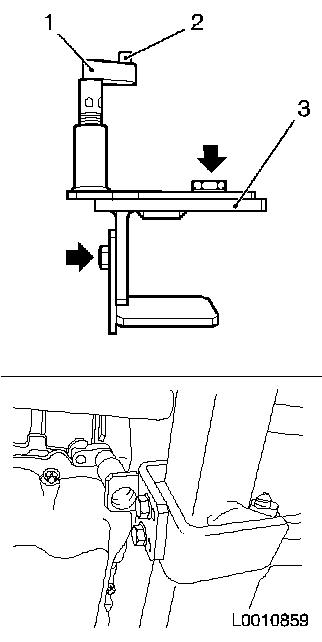

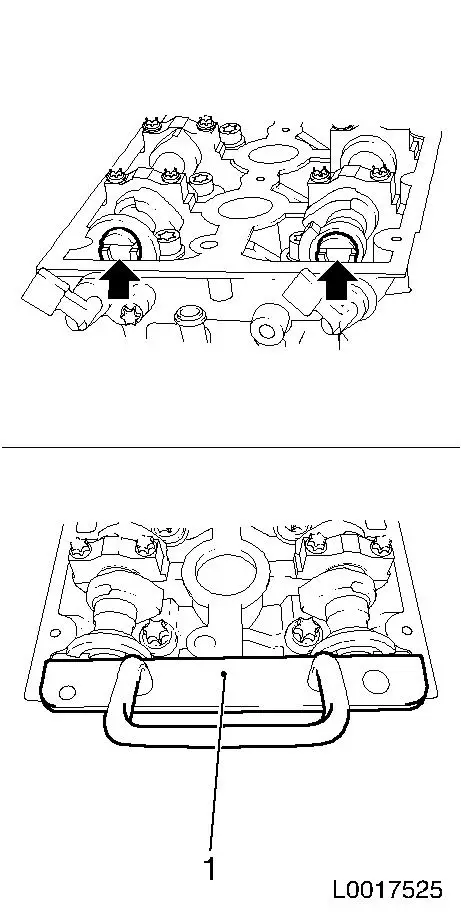

Insert KM-6173 (3)

| • |

Slacken 4x bolts (arrows) and hand-tighten

|

| • |

Align KM-6173 at front axle body

|

| • |

Wind up the support bearing (1)

| – |

Journal (2) must sit in mount at cylinder block

|

|

|

|

|

|

| 24. |

Attach KM-6001-A (1)

Note: Attaching KM-6001-A guarantees perfect alignment of the

drive unit with the front axle body.

| • |

Slacken 3x bolts (arrows) in adjusting rails

|

| • |

Insert KM-6001-A

| – |

The journals (2) and (5) must sit in the guide holes of the

front axle body

|

|

| • |

Tighten 3x bolts in adjusting rails

|

| • |

Adjust support bearings, front (4) and rear (3)

| – |

Raise support bearings up to the stop on the guide journals

Note: The guide

journals must be seated free from play in the support bearings.

|

|

|

|

| 25. |

Lower vehicle by its full height

|

| 26. |

Remove engine damping block, right hand side

|

|

|

| 27. |

Remove engine damping block support (1)

|

|

|

| 28. |

Remove front toothed belt cover (centre) (1)

| • |

Unclip 2x from rear of toothed belt cover

|

|

|

|

| 29. |

Stop toothed belt tensioner

| • |

Apply tension to toothed belt tension roller (2) clockwise

using an Allen key (1), and fix using KM-6333 (3)

|

|

|

|

| 31. |

Remove toothed belt tensioner (2)

Note: Do not remove

locking using KM-6333 (3).

|

|

|

| 32. |

Raise vehicle by its full height

|

| 33. |

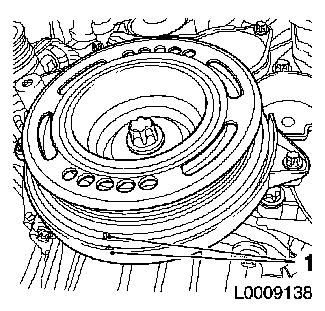

Attach fastening bolt with washer to the torsional vibration

damper of the crankshaft. Tighten by hand.

|

| 34. |

Remove KM-6625

| • |

Detach screwed connection

|

|

| 35. |

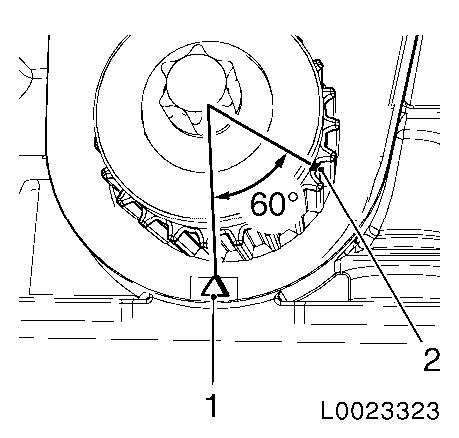

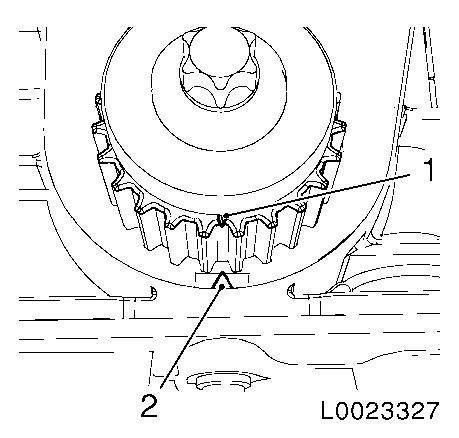

Turn the crankshaft 60° against the direction of engine

rotation to the fastening bolt of the torsional vibration

damper

Note: Check using the

TDC marks on the toothed belt drive gear (1) and oil pump housing

(2)

|

|

|

| 36. |

Lower vehicle by its full height

|

| 37. |

Place collecting basin underneath.

|

| 38. |

Unscrew closure bolt, exhaust camshaft adjuster

|

| 39. |

Unscrew intake camshaft closure bolt

|

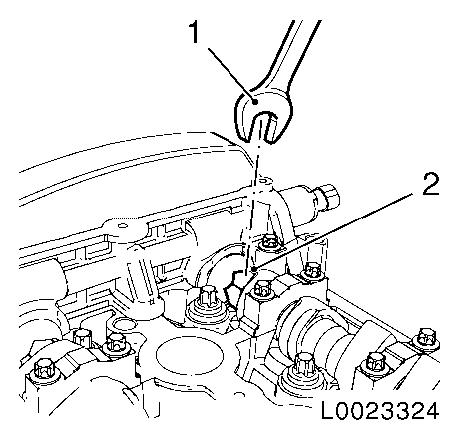

| 40. |

Slacken exhaust camshaft adjuster

Note: 2 mechanics

required

| • |

Counterhold against the camshaft hex (2) using an open-ended

spanner socket (1)

|

|

|

|

| 41. |

Detach exhaust camshaft adjuster

|

| 42. |

Slacken intake camshaft adjuster

Note: 2 mechanics

required

| • |

Counterhold against the camshaft hex (2) using an open-ended

spanner socket (1)

|

|

|

|

| 43. |

Detach intake camshaft adjuster

|

| 44. |

Remove rear toothed belt cover

| • |

Unclip wiring trough cover

|

|

| 45. |

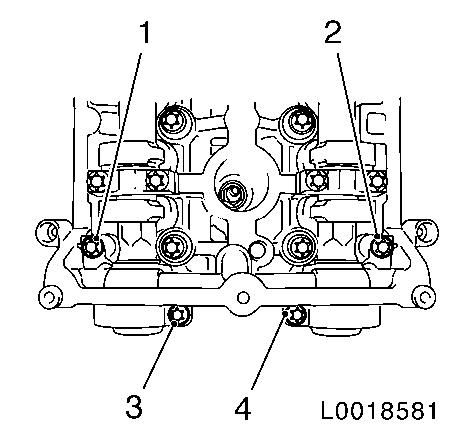

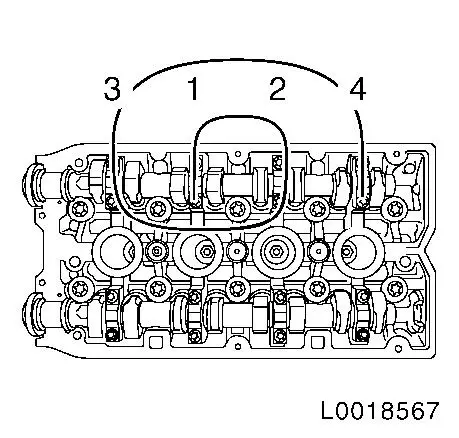

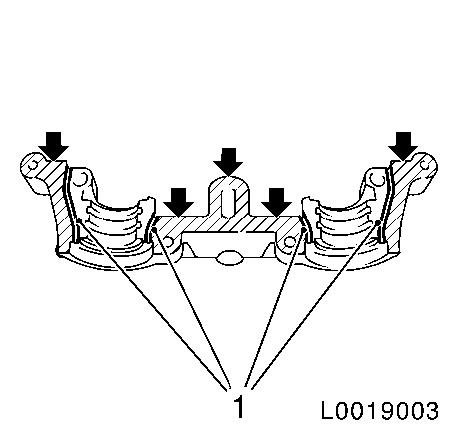

Remove camshaft bearing support

| • |

Unscrew 4x bolts

| – |

Note removal sequence 1 - 4

|

|

| • |

Release bearing support by striking it gently with a plastic

hammer

|

|

|

|

| 46. |

Remove intake camshaft

Note: Mark the camshaft

bearing caps before removing them.

| • |

Slacken camshaft bearing caps 1 - 4, working in spiral from

outside to inside in steps of 1/2 up to 1 turn

|

| • |

Remove the camshaft bearing cover from the cylinder head and

take out the camshaft

Note: Note marking on

the camshaft bearing cap with stamped numbers from 1 to 8 (there is

a dot at bottom left before each number to avoid mistakes).

|

|

|

|

|

| 47. |

Remove exhaust camshaft

Note: Mark the camshaft

bearing caps before removing them.

| • |

Slacken camshaft bearing caps 5 - 8, working in spiral from

outside to inside in steps of 1/2 up to 1 turn

|

| • |

Remove the camshaft bearing cover from the cylinder head and

take out the camshaft

Note: Note marking on

the camshaft bearing cap with stamped numbers from 1 to 8 (there is

a dot at bottom left before each number to avoid mistakes).

|

|

|

| 48. |

Remove cup tappet with KM-845 (1)

|

|

|

| 49. |

Determine cup tappet size

|

Example of determining the size of a cup tappet,

intake side:

|

|

Dimension of fitted cup tappet

|

|

3.20 mm

|

(Identification no. 20)

|

|

Valve clearance measurement between cams and cup tappets

|

+

|

0.35 mm

|

|

| |

=

|

3.55 mm

|

|

|

Required value, valve lash, intake side

|

-

|

0.25 mm

|

|

|

Nominal dimension of the new cup tappet

|

|

3.30 mm

|

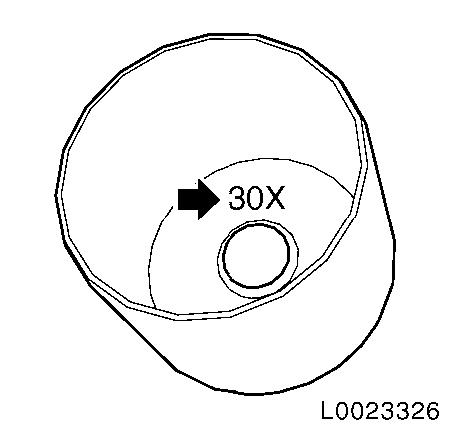

(Identification number 30X)

|

Note: The identification

number (arrow) is on the inside of the cup tappet

| • |

Now use a cup tappet with this dimension or one that is nearest

to it

Currently available cup tappet sizes

|

|

|

|

Install

Install

| 50. |

Insert cup tappet with KM-845

| • |

Lightly coat sliding surfaces with oil

|

|

| 51. |

Install intake camshaft

| • |

Coat with MoS 2 lubricating paste

|

| • |

Insert camshaft

Note: Note the

identification marking on the camshaft bearing cover.

|

| • |

Install camshaft bearing cover

| – |

Tighten camshaft bearing caps 1 - 4 in a spiral from the inside

outward 8 Nm

Note: Note correct

tightening sequence 1 - 4.

|

|

|

|

|

| 52. |

Install exhaust camshaft

| • |

Coat with MoS 2 lubricating paste

|

| • |

Insert camshaft

Note: Note the

identification marking on the camshaft bearing cover.

|

| • |

Install camshaft bearing cover

| – |

Tighten camshaft bearing caps 1 - 8 in a spiral from the inside

outward 8 Nm

Note: Note correct

tightening sequence 1 - 4.

|

|

|

|

|

| 53. |

Clean sealing surfaces of 1st camshaft bearing support and the

cylinder head with a suitable tool, e.g. plastic wedge

| • |

Free oil duct (arrow) from any sealant residue

|

|

|

|

| 54. |

Place the camshaft bearing cap on the cylinder head without

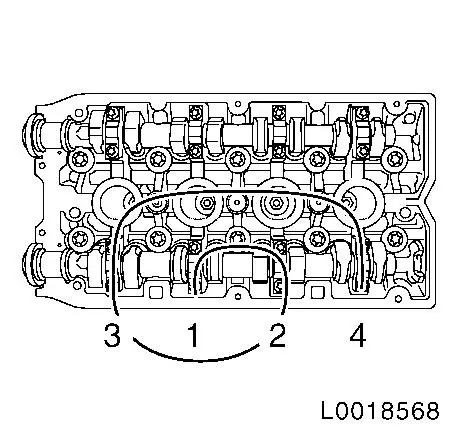

sealant and hand-tighten the bolts (approx. 2 Nm )

Note: Note correct

tightening sequence 1 - 4.

|

|

|

| 55. |

Fit the camshaft adjuster for the intake camshaft to the intake

camshaft

|

| 56. |

Fit the camshaft adjuster for the exhaust camshaft to the

exhaust camshaft

|

Important: If the actual value

deviates from the required value, these values must be noted and

the adjustment procedure repeated

|

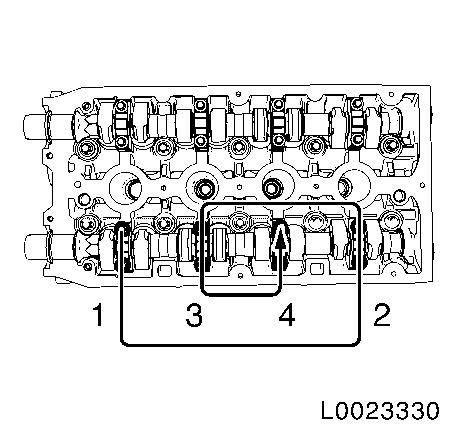

| 57. |

Check the valve clearance at both intake valves for cylinder

1

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 1 are

located in test position (1)

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

|

|

|

|

| 58. |

Check the valve clearance at both intake valves for cylinder

3

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 3 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

| 59. |

Check the valve clearance at both intake valves for cylinder

4

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 4 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

| 60. |

Check the valve clearance at both intake valves for cylinder

2

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 2 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

Important: If the actual value

deviates from the required value, these values must be noted and

the adjustment procedure repeated

|

| 61. |

Check the valve clearance at both exhaust valves for cylinder

4

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 4 are

located in test position (1)

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

|

|

| 62. |

Check the valve clearance at both exhaust valves for cylinder

2

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 2 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 63. |

Check the valve clearance at both exhaust valves for cylinder

1

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 1 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 64. |

Check the valve clearance at both exhaust valves for cylinder

3

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 3 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 65. |

Detach camshaft adjuster for intake camshaft

| • |

Counterhold against the intake camshaft hex

|

|

| 66. |

Detach camshaft adjuster for exhaust camshaft

| • |

Counterhold against the exhaust camshaft hex

|

|

| 67. |

Detach camshaft bearing support

|

Important: It is necessary to

ensure that no sealant is applied outside the designated sealing

surfaces.

|

| 68. |

Apply surface sealant to sealing surfaces (arrows) of the

camshaft bearing support thinly and evenly

Note: The grooves (1)

adjacent to the sealing surfaces must remain free from sealant.

|

|

|

| 69. |

Place the camshaft bearing support on the cylinder head and

hand-tighten the bolts (approx. 2 Nm

)

Note: Note correct

tightening sequence 1 - 4.

|

|

|

| 70. |

Install 2x camshaft seal ring

| • |

Hoist the seal ring (3) using KM-422

(4) on the camshaft until this abuts against the cylinder head

| – |

To install, use camshaft sprocket bolt (1) in conjunction with

shims (2) with a total thickness of approx. 10 mm

|

|

|

|

|

| 71. |

Tighten the camshaft bearing support

Important: No sealant may reach

the camshafts.

|

| • |

Tighten 4x bolt 8 Nm

| – |

Note correct tightening sequence 1-4

|

|

|

|

|

| 72. |

Clean 4x thread, rear toothed belt cover

|

| 73. |

Install rear toothed belt cover

| • |

Tighten 4x new bolt 6 Nm

| – |

Coat 4x bolt with locking compound

|

|

| • |

Clip in wiring trough cover

|

|

| 74. |

Attach exhaust camshaft adjuster

| • |

Insert new sealing sleeve in adjuster

|

|

| 75. |

Attach intake camshaft adjuster

| • |

Insert new sealing sleeve in adjuster

|

|

| 76. |

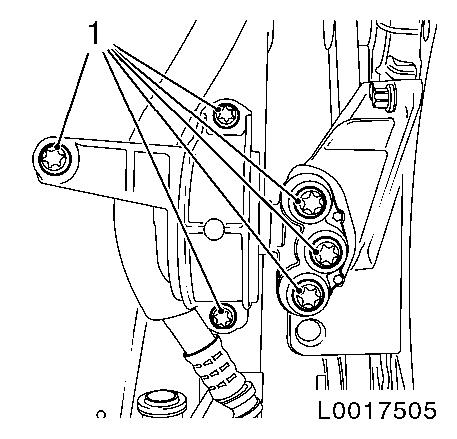

Insert KM-6328-A (1) into

camshafts

Note: Align camshafts

horizontally by the hexagon until KM-6328-A (1) can be inserted in the grooves

(arrows)

|

|

|

| 77. |

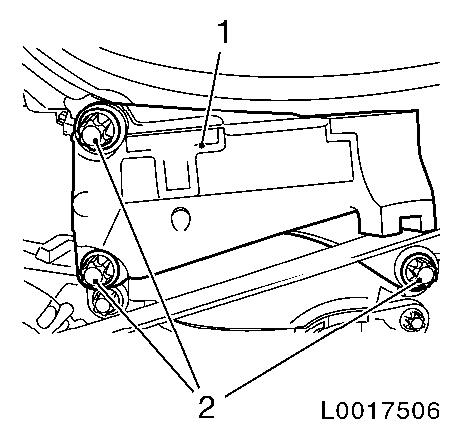

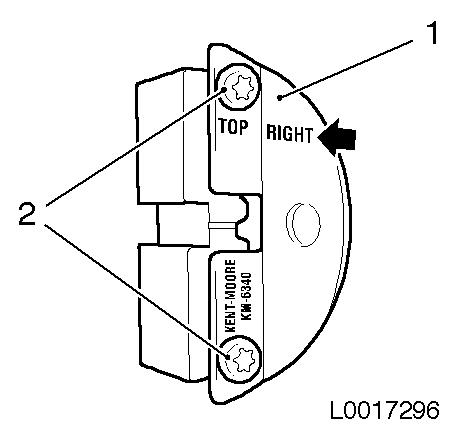

Prepare KM-6340-Right for use on

engines A16XER, Z16XER, A18XER and Z18XER

| • |

Detach front panel (1) from KM-6340-Right

Unscrew 2x bolts (2)

|

|

|

|

| 78. |

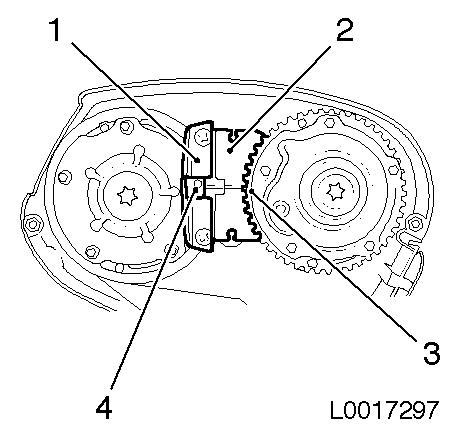

Insert KM-6340 into camshaft

sprockets

Insert KM-6340-Left (1) and KM-6340-Right (2) in the camshaft adjuster as

shown

Note: The spot-type

marking (4) on the intake camshaft adjuster does not correspond to

the groove of KM-6340-Left during this

process but must be somewhat above as shown

The spot type marking (3) on the exhaust camshaft adjuster must

correspond to the groove on KM-6340-Right

|

|

|

| 79. |

Fasten exhaust camshaft adjuster

Note: 2 mechanics

required

| • |

Tighten bolt 65

Nm+125°+15°

|

| • |

Counterhold at camshaft hexagon

|

|

| 80. |

Fasten intake camshaft adjuster

Note: 2 mechanics

required.

| • |

Tighten bolt 65

Nm+125°+15°

|

| • |

Counterhold at camshaft hexagon

|

|

| 81. |

Tighten exhaust camshaft adjuster closure bolt 30 Nm

|

| 82. |

Tighten closure bolt, intake camshaft adjuster 30 Nm

|

| 84. |

Raise vehicle by its full height

|

| 85. |

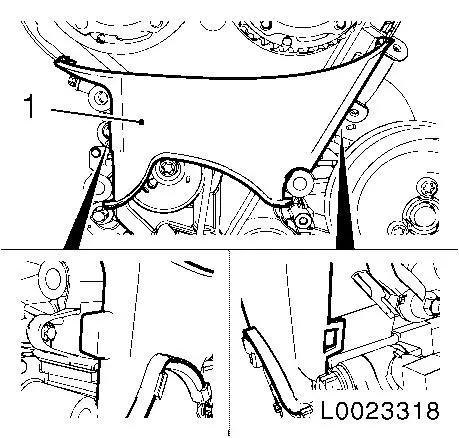

Rotate the crankshaft about 60° in the direction of engine

rotation against the torsional vibration damper bolt

| • |

Marking, toothed belt drive gear (1) and oil pump housing (2)

must align

|

|

|

|

| 86. |

Block crankshaft.

| • |

Insert KM-6625

| – |

Install bolted connection

|

|

|

| 87. |

Lower vehicle by its full height

|

| 88. |

Clean thread, toothed belt tensioner

|

|

| 89. |

Intake toothed belt tensioner

| • |

Insert toothed belt tension roller

| – |

Free leg of spring (1) of the toothed belt tension roller must

engage in the cut-out (arrow) of the pump module

|

|

| • |

Tighten bolt 20 Nm + 120° +

15°

|

|

|

| 90. |

Remove fastening bolt with washer from the torsional vibration

damper of the crankshaft

|

Important: Use assembly tool.

|

| 91. |

Insert toothed belt

|

| 92. |

Release tension on toothed belt tensioner

| • |

Apply preliminary tension clockwise to toothed belt tension

roller

|

|

| 93. |

Raise vehicle by its full height

|

| 94. |

Install front toothed belt cover (lower)

|

| 95. |

Install torsional vibration damper

Important: Use new bolt.

|

| • |

Tighten bolt 95 Nm + 45° +

15°

|

|

| 96. |

Remove KM-6625

| • |

Detach screwed connection

|

| • |

Tighten screwed joint 40 Nm

|

|

| 97. |

Lower vehicle by its full height

|

| 99. |

Check position of camshaft sprockets

| • |

Turn crankshaft 720° in the direction of engine rotation by

the bolt on the torsional vibration damper

Note: Note marking,

camshaft sprockets.

|

| • |

Insert KM-6340 into camshaft

sprockets

|

|

| 100. |

Check camshaft positions

Insert KM-6628-A into camshafts

Note: If KM-6628-A cannot be inserted in the camshafts, the

timings must be set

|

| 101. |

Raise vehicle by its full height

|

| 102. |

Check crankshaft position

| • |

Marking on torsional vibration damper must align with the

marking (1) on the lower part of the toothed belt cover

|

|

|

|

| 103. |

Lower vehicle by its full height

|

| 104. |

Insert front toothed belt cover (centre)

| • |

Clip 2x onto the rear toothed belt cover

|

|

| 105. |

Install support for engine damping block

|

| 106. |

Install engine damping block

| • |

Fasten engine bracket adapter

|

| • |

Fasten engine damping block

|

|

| 107. |

Raise vehicle by its full height

|

| 108. |

Remove KM-6001-A

| • |

Slacken 3x screwed connections

|

|

| 110. |

Clean thread of bolt, ribbed V-belt tensioner

|

| 111. |

Install ribbed V-belt tensioner

|

| 112. |

Lower vehicle by its full height

|

| 114. |

Install cylinder head cover

|

| 116. |

Install front toothed belt cover (top)

|

| 117. |

Install air cleaner housing

- A 16 XER, Z 16 XER

- A 18 XER, Z 18 XER

|

| 118. |

Connect battery

| • |

Attach ground connection to ground terminal

|

|

| 119. |

Program volatile memories

|

|