|

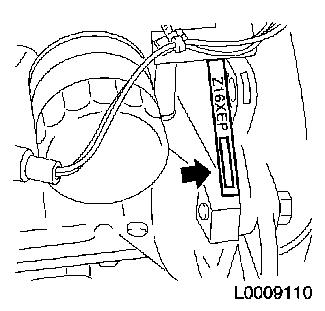

Repair Engine Using An Engine Short Block

(Z16XE1)

Remove Remove

| 2. |

Remove transmission from engine

| 1. |

Manual transmission  |

| 2. |

MTA manual transmission  |

|

| 3. |

Place collecting basin underneath.

|

| 4. |

Drain engine oil

| • |

Tighten drain bolt 14 Nm

|

|

| 5. |

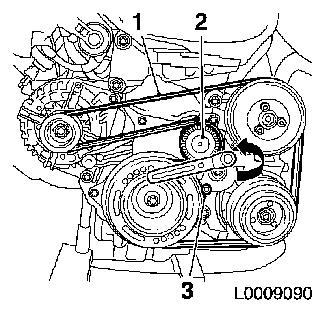

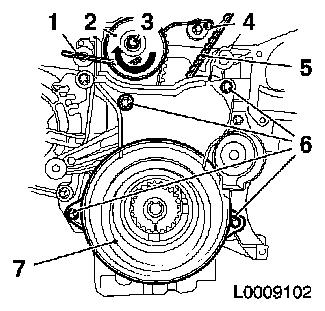

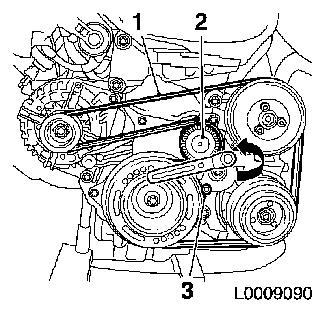

Detach ribbed V-belt (1)

| • |

Mark direction of rotation

|

| • |

Apply tension to ribbed V-belt tensioner (2) in the direction

of the arrow and fix with KM-6130 (3)

|

|

|

|

| 6. |

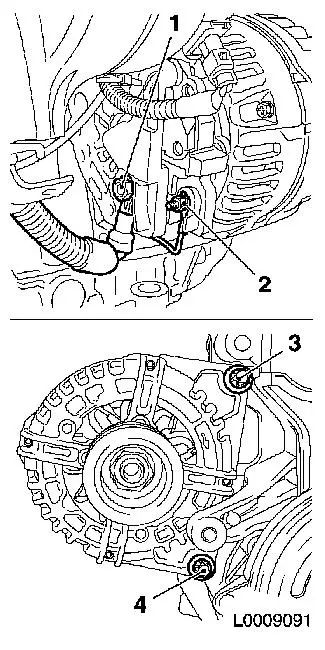

Detach alternator

| • |

Disconnect alternator from power supply

| – |

Unscrew 2x nuts (1) and (2)

|

|

| • |

Unscrew 2x bolts (3) and (4)

|

|

|

|

| 7. |

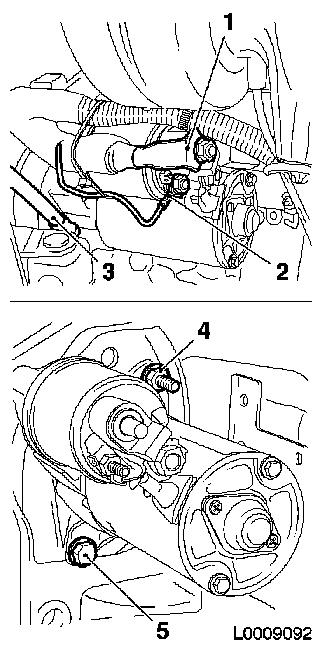

Detach starter

| • |

Detach cable (1) and (2)

|

| • |

Disconnect earth cable (3)

|

| • |

Unscrew 2x fastening bolt (4) and (5)

|

|

|

|

| 8. |

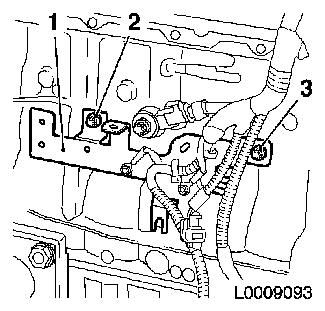

Detach intake manifold support

|

| 9. |

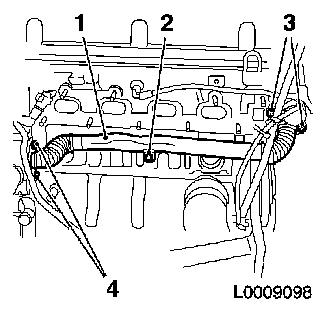

Detach wiring harness bracket (1) from cylinder block

| • |

Unscrew 2x bolts (2) and (3)

|

|

|

|

| 10. |

Detach intake manifold

|

| 11. |

Detach engine transport shackle, intake side

|

| 12. |

Detach engine transport shackle, exhaust side

|

| 13. |

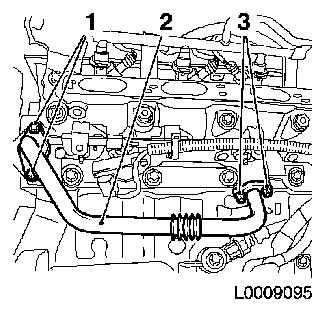

Detach exhaust gas recirculation metal tube (2)

| • |

Unscrew 4x bolt (1) and (3)

|

|

|

|

| 14. |

Detach exhaust manifold

|

| 15. |

Take out oil dipstick guide tube

|

| 16. |

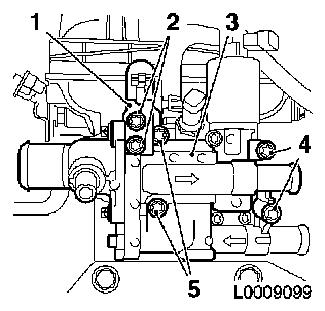

Remove coolant pipe (1)

| • |

Unscrew 5x bolts (2), (3) and (4)

|

|

|

|

| 17. |

Detach coolant flange (3)

| • |

Unscrew 4x bolts (4) and (5)

|

|

|

|

| 18. |

Block flywheel using KM-652

|

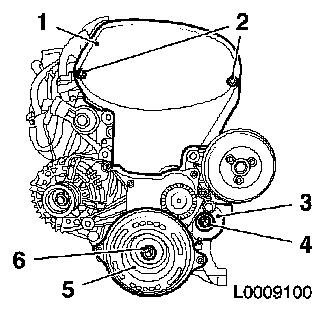

| 19. |

Remove ribbed V-belt tensioner (3)

Note: Ribbed V-belt

tensioner remains locked with KM-6130

|

| 20. |

Detach toothed belt cover (top) (1)

|

| 21. |

Detach torsional vibration damper (5)

|

|

|

| 22. |

Detach lower part of toothed belt cover (7)

|

| 23. |

Stop toothed belt tensioner

| • |

Apply tension in the direction of the arrow with an Allen key

(1) and lock with KM-6333 (4)

|

|

| 24. |

Remove toothed belt (5)

| • |

Mark direction of rotation

|

|

| 25. |

Detach toothed belt tensioner (2)

|

|

|

| 26. |

Detach right engine damping block support

|

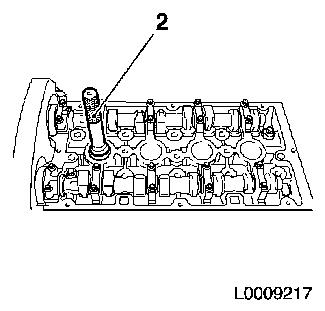

| 27. |

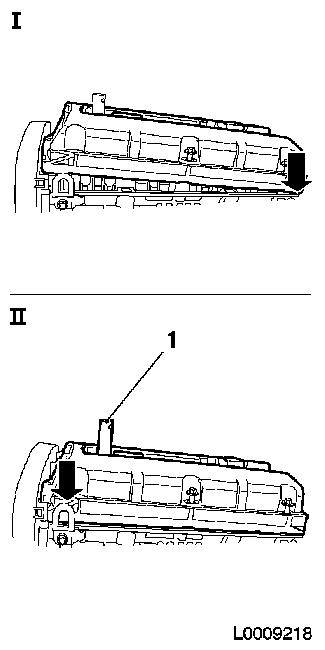

Remove DIS-ignition module

| • |

Remove cover of DIS-ignition module in the direction of the

arrow

Note: Note arrow on

cover

|

| • |

Remove from spark plugs using KM-6009

(1)

|

|

|

|

| 28. |

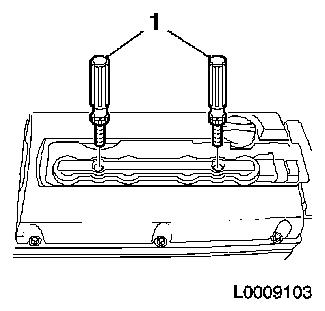

Detach cylinder head cover (1)

| • |

Unlatch and remove engine vent pipe

|

| • |

Slacken 3x bolt (3) pull upwards and fix in this position with

adhesive tape

|

| • |

Slacken 6x bolts (2)

Note: Care should be

taken that the area of the front camshaft bearing caps (arrows) is

clean and free from remains of sealant

|

|

|

|

Important: Remove cylinder head

only when engine is cold (room temperature)

|

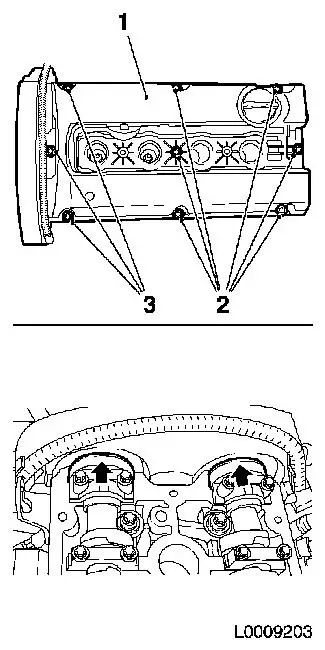

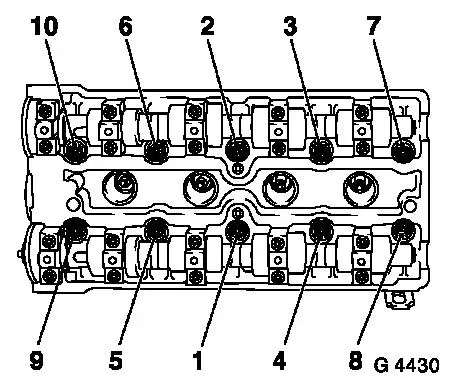

| 29. |

Remove cylinder head

| • |

Unscrew 10x bolt

Note: Unfasten bolts in

the order shown

|

|

|

|

| 30. |

Remove cylinder head

Note: Second

mechanic

| • |

Lay cylinder head on suitable base

|

| • |

Remove cylinder head gasket

|

|

Important: Remove gasket residue

and clean sealing surfaces. Do not use sharp metal tools. Take care

not to damage the sealing surfaces of the cylinder head

|

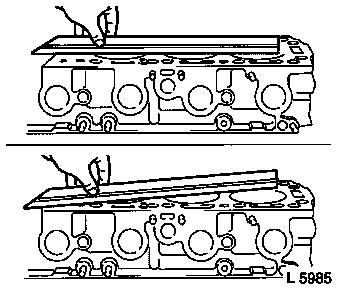

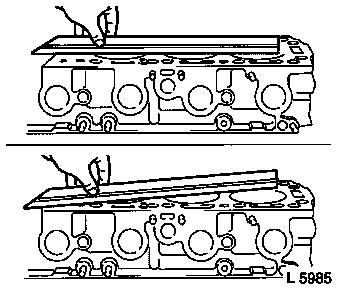

| 31. |

Check for plane surface

| • |

Use a straight edge to check the cylinder head and cylinder

block lengthwise, widthwise and diagonally for distortion

|

|

|

|

| 32. |

Remove cylinder head

Note: Second

mechanic

| • |

Lay cylinder head on suitable base

|

| • |

Remove cylinder head gasket

|

|

| 33. |

Detach thrust plate and clutch disk

|

| 35. |

Release flywheel lock

|

| 36. |

Rotate engine on engine overhaul stands through 180°

|

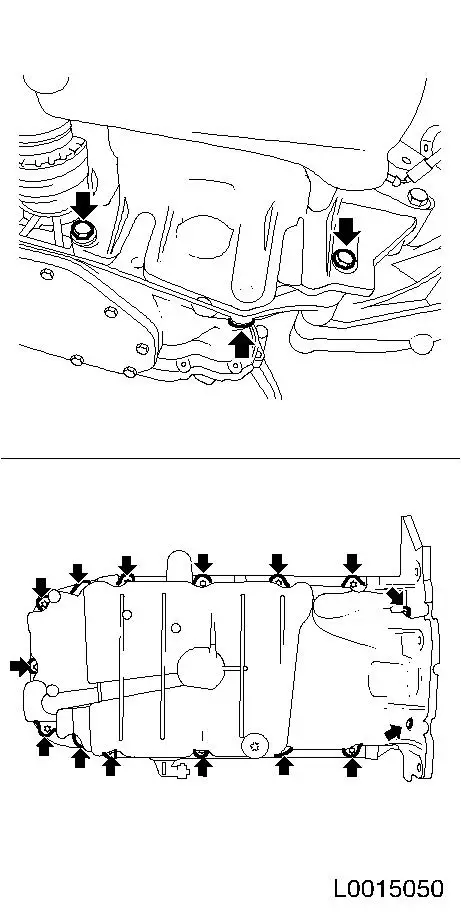

| 37. |

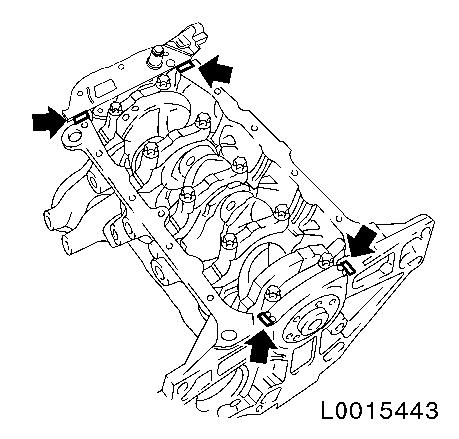

Loosen oil pan

| • |

Remove 3x bolt (arrows) from transmission

|

| • |

Remove 15x bolts (arrows) from engine block

|

|

|

|

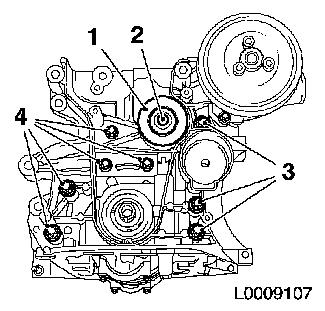

| 38. |

Detach toothed belt guide roller (1)

|

| 39. |

Remove pump module

| • |

Unscrew 8x bolts (3) and (4)

Note: Note different

screw lengths

|

|

|

|

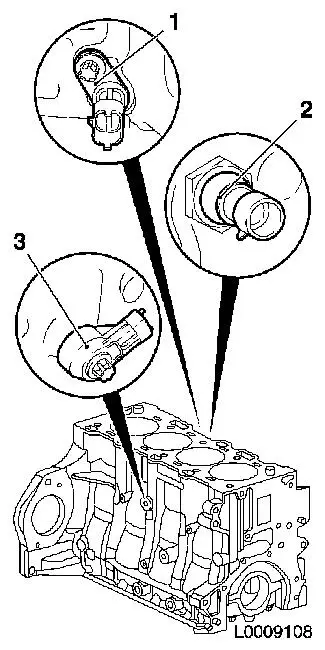

| 40. |

Detach knock sensor (3)

|

| 41. |

Detach oil pressure switch (2)

|

| 42. |

Remove crankshaft sensor (1)

|

|

|

Install

Install

| 43. |

Emboss engine number

| • |

Onto flattened area on cylinder block (arrow) with numbers

punches

|

|

|

|

| 44. |

Clean sealing surfaces.

|

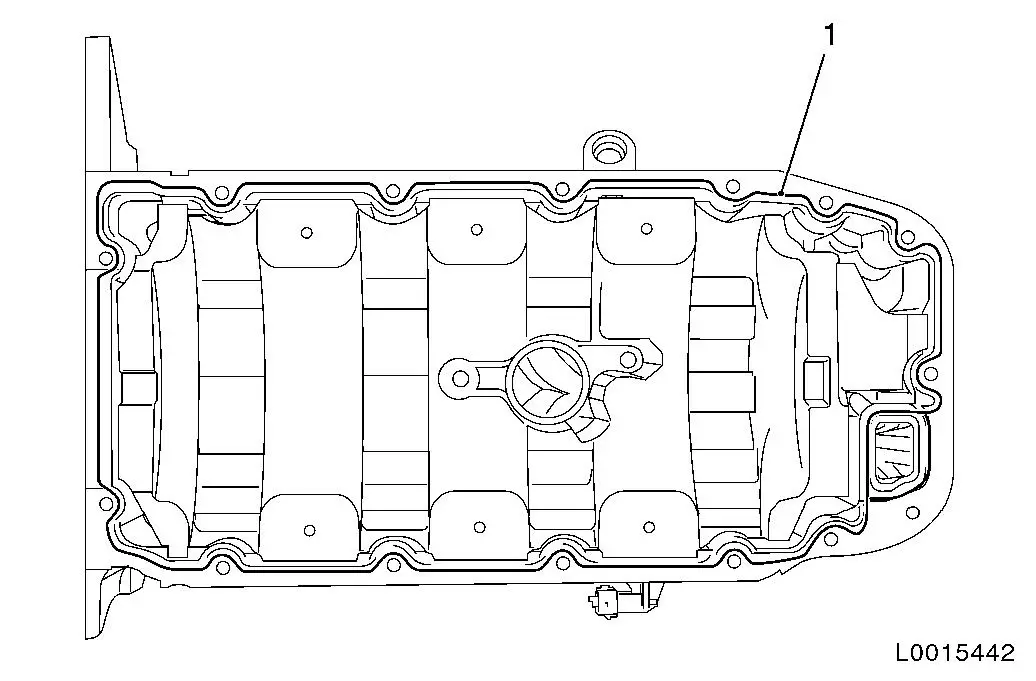

| 46. |

Apply an approx. 3.5 mm thick bead of oil pan sealant to the

joints (arrows)

|

|

|

|

| 47. |

Apply oil pan sealant to the oil pan

Note: The assembly time

including torque check must take no longer than 10 min•

| • |

Apply an approx. 3.5 mm thick bead of oil pan sealant (1) as

illustrated

|

|

|

| 48. |

Install oil pan

| • |

Tighten 15x bolt on cylinder block and pump module 10 Nm

|

| • |

Tighten 3x bolt on transmission 40

Nm

|

|

| 49. |

Attach crankshaft sensor 8 Nm

|

| 50. |

Attach knock sensor 20 Nm

|

| 51. |

Attach oil pressure switch 20 Nm

|

| 52. |

Install pump module

| • |

Replace gasket

Note: Note different

screw lengths

|

|

| 53. |

Insert toothed belt guide roller

| • |

Tighten bolt 20 Nm + 120° +

15°

|

|

| 54. |

Fit flywheel

| • |

Tighten 6x bolt 35 Nm + 30° +

15°

| – |

Apply screw locking compound

|

|

|

| 55. |

Attach thrust plate and clutch disk

|

Important: Remove gasket residue

and clean sealing surfaces. Do not use sharp metal tools. Take care

not to damage the sealing surfaces of the cylinder head

|

| 56. |

Check for plane surface

| • |

Use a straight edge to check the cylinder head and cylinder

block lengthwise, widthwise and diagonally for distortion

|

|

|

|

| 57. |

Position cylinder head

Note: Second

mechanic

| • |

Install cylinder head gasket

|

Important: Check installation

position

|

| • |

Position cylinder head

|

|

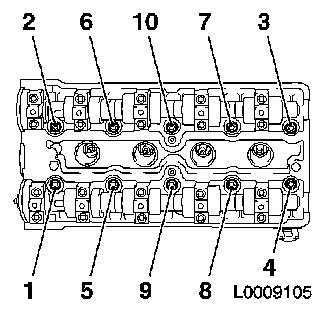

| 58. |

Install cylinder head

| • |

Tighten 10x bolt 25 Nm + 90° +

90° + 90° + 45°

Note: Note correct

tightening sequence

| – |

Use new cylinder head bolts

|

|

|

|

|

| 59. |

Attach toothed belt tensioner

| • |

Tighten bolt 20 Nm + 120° +

15°

|

|

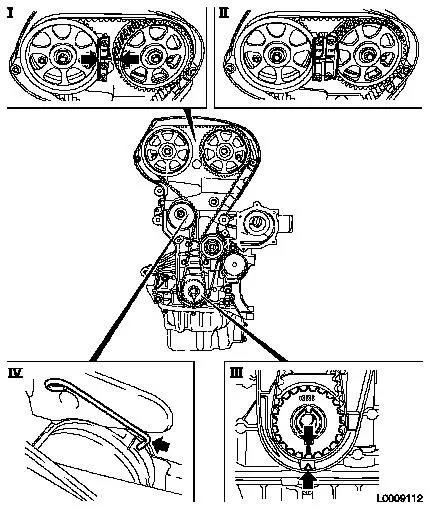

| 60. |

Set crankshaft to cylinder 1 TDC of combustion stroke

| • |

Marking on toothed belt drive gear and timing case

|

|

| 61. |

Position toothed belt

| • |

Move crankshaft in direction of engine rotation to "cylinder 1

TDC of combustion stroke" (III)

|

| • |

Position camshaft sprockets in such a way that the markings

(arrows) are opposite each other

|

| • |

Attach KM-6340-Left to intake

camshaft sprocket (I)

|

| • |

Insert KM-6340-Right (II)

|

| • |

Lock toothed belt tensioner with KM-6333 (IV)

|

| • |

Position toothed belt

| – |

Note direction of travel

|

|

|

| 62. |

Timing, Check

| • |

Move crankshaft by two revolutions (720°) in direction of

engine rotation to "Cylinder 1 TDC of combustion stroke" mark

(III)

|

| • |

Markings on the camshaft sprockets must be exactly opposite

each other (I)

|

|

|

|

| 63. |

Check valve lash and adjust if necessary

|

| 64. |

Attach toothed belt cover at the bottom

|

| 65. |

Fit torsional vibration damper

Important: Use new bolt

|

| • |

Lock flywheel with KM-911 or KM-6625

|

| • |

Tighten bolt 95 Nm + 45° +

15°

|

|

| 66. |

Attach ribbed V-belt tensioner

|

| 67. |

Attach right engine damping block support

|

| 68. |

Attach coolant flange

|

| 69. |

Attach wiring harness bracket to coolant flange

|

| 71. |

Attach exhaust manifold

|

| 72. |

Attach catalytic converter support to catalytic converter

|

| 73. |

Install dipstick guide tube

|

| 74. |

Attach heat shield to exhaust manifold

|

| 75. |

Attach exhaust gas recirculation metal tube

|

| 76. |

Install intake manifold

|

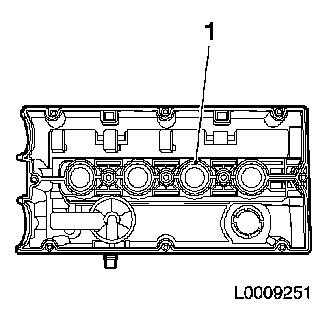

| 77. |

Replace gasket, cylinder head cover

| • |

Insert new gasket (1) in cylinder head cover

|

|

|

|

| 78. |

Remove spark plug, cylinder 1

|

| 79. |

Install KM-6354 in spark plug thread,

cylinder 1

|

|

|

Important: When assembling the

cylinder head cover, care must be taken that the gasket of the

cylinder head cover does not become detached. An incorrectly fitted

gasket in the cylinder head cover can cause serious damage to the

engine

|

| 80. |

Place cylinder head cover in position

| • |

Lift cylinder head cover via KM-6354

|

| • |

Position cylinder head cover at the rear (i)

|

| • |

Press cylinder head cover carefully downwards at the back

(II)

|

|

|

|

| 81. |

Attach cylinder head cover

| • |

Remove adhesive tape from 3 bolts

|

| • |

Attach engine vent pipe and latch

|

|

| 82. |

Install spark plug, cylinder 1

| • |

using KM-6363

| – |

Tightening torque 25 Nm

|

|

|

| 83. |

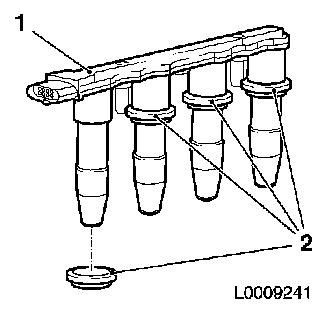

Attach DIS-ignition module (1)

| • |

Attach DIS ignition module cover

|

|

|

|

| 84. |

Attach engine transport shackle, exhaust side

|

| 85. |

Attach engine transport shackle, intake side

|

| 86. |

Attach wiring harness bracket to cylinder block

|

| 89. |

Clip engine wiring harness to bracket

|

| 90. |

Attach wiring harness bracket to cylinder head

|

| 91. |

Insert ribbed V-belt

Note: Observe direction

of rotation

| • |

Apply tension to ribbed V-belt tensioner (2) in the direction

of the arrow (anti-clockwise) and place ribbed V-belt in position

(1)

|

|

|

|

| 92. |

Attach toothed belt cover upper section

|

| 93. |

Attach transmission to engine

| 1. |

Manual transmission  |

| 2. |

MTA manual transmission  |

|

| 95. |

Top up engine oil.

| • |

Check engine oil level and top up if necessary

|

|

|