|

Dismantle and assemble main shaft (F13/F13

MTA)

Note: Transmission

remains installed.

Overview of Drive Shaft

Remove Remove

|

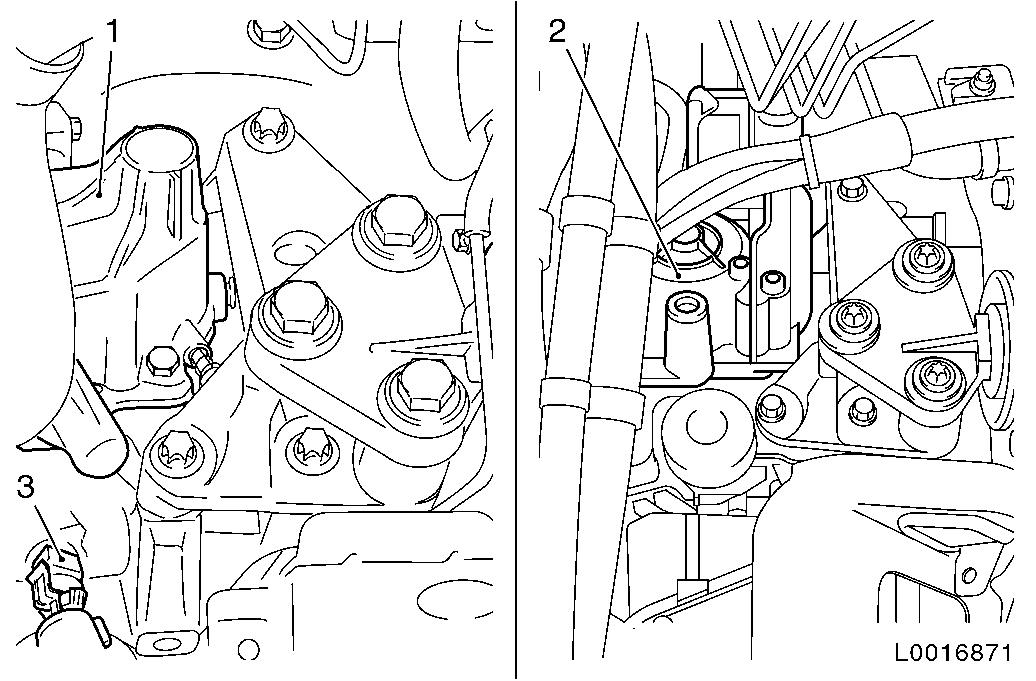

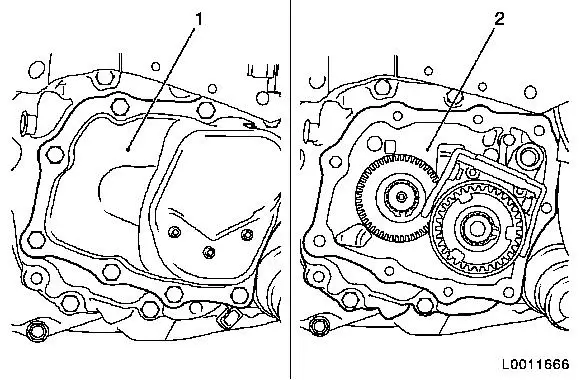

| 1. |

Remove gearbox cover (1)

Note: For F13

transmission.

Remove gearshift module (2)

Note: For F13 MTA

transmission.

|

| 2. |

Remove reversing lamps switch (3).

| • |

Disconnect wiring harness plug, reversing lamp switch

|

| • |

Unscrew reversing lamp switch

|

|

|

|

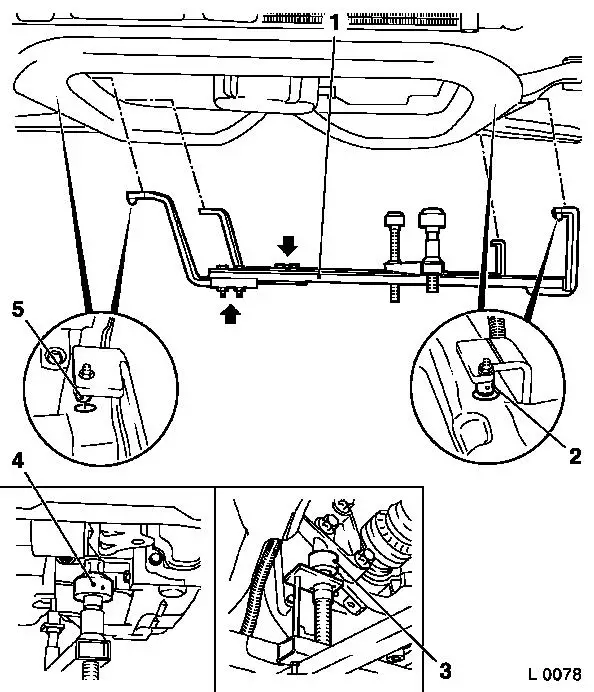

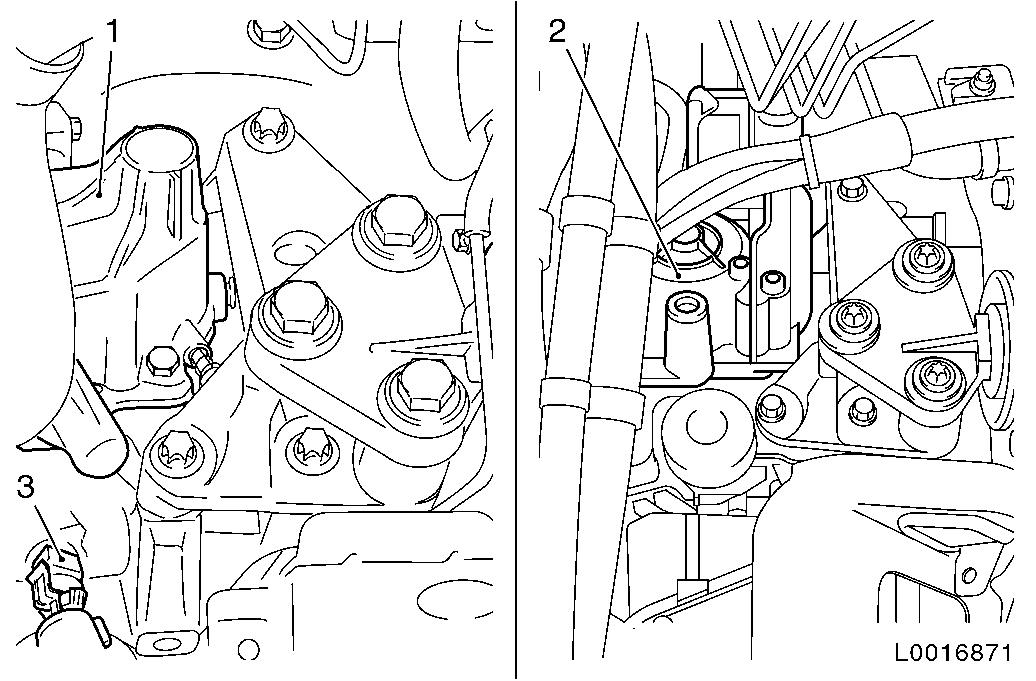

| 3. |

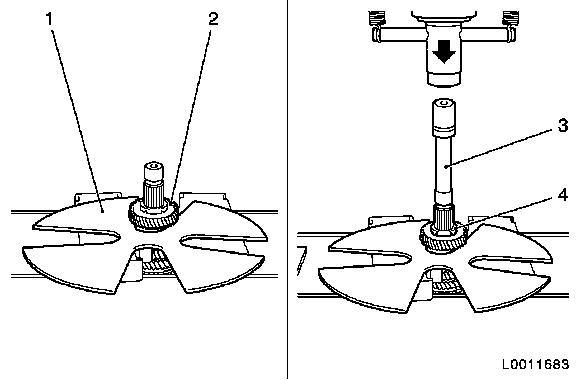

Attach KM-6001-B to front axle

body

Note: The guide pins

must sit in the support bearing with no play.

| • |

Release 2x bolt (arrows) for adjustment rails on KM-6001-B (1)

|

| • |

Insert KM-6001-B as shown

Note: 2x journals (2)

and (5) must sit flush in the guide holes of the front axle

body.

|

| • |

Tighten 2x bolt for adjustment rails

|

| • |

Twist up front support bearing (4)

| – |

until the guide pin is in contact with the front of the engine

damping block

|

|

| • |

Twist up rear support bearing (3)

| – |

until the guide pin is in contact with the rear of the engine

damping block

|

|

|

|

| 4. |

Remove front axle body

|

Important: Do not damage wiring

harnesses and attaching parts

|

| 5. |

Lower engine and transmission on the left hand side

|

|

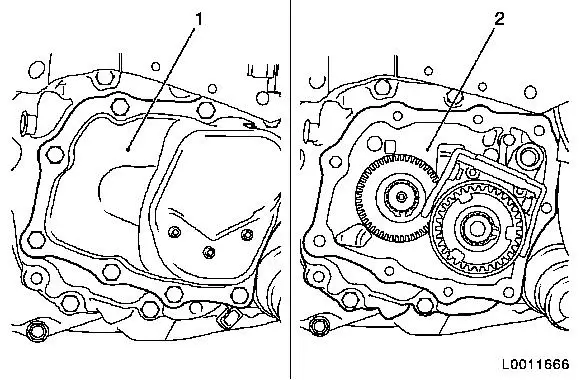

| 6. |

Remove end shield (1) cover

|

|

| 8. |

Remove main shaft

Note: If the gear

wheels are damaged, the entire gear cluster must be replaced.

|

|

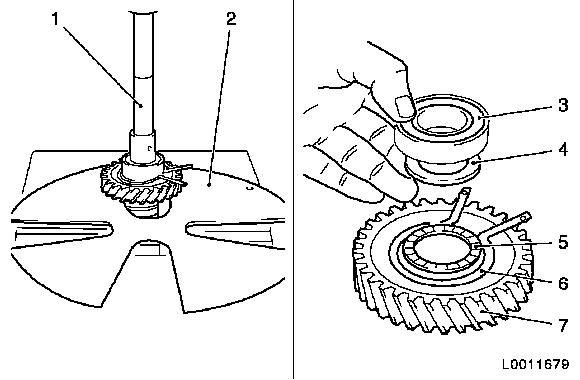

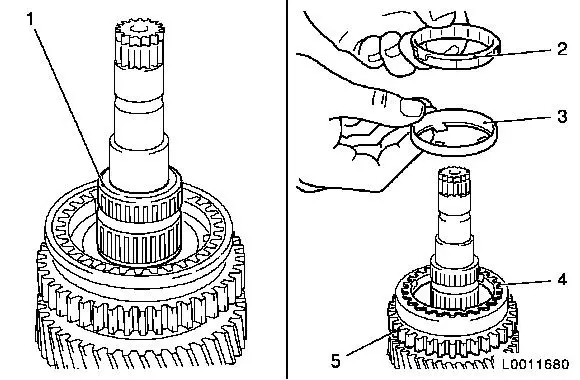

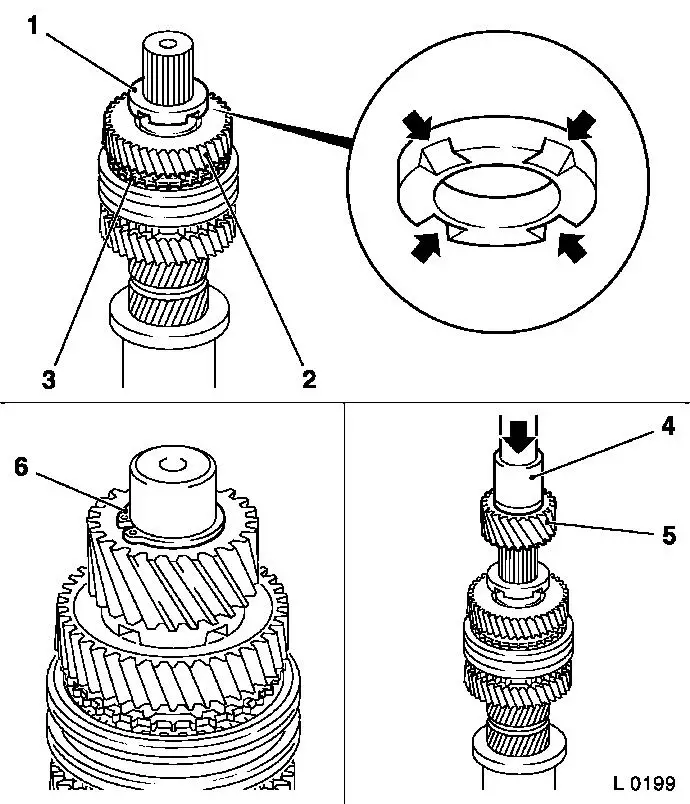

| 9. |

Detach gear wheel, 1st gear (7).

| • |

Press 1st gear off main shaft with KM-307-B (2) and KM-736

(1).

|

| • |

Remove ball bearing (3), and thrust washer (4)

|

| • |

Remove axial needle bearing (5) and retaining ring (6)

|

|

|

|

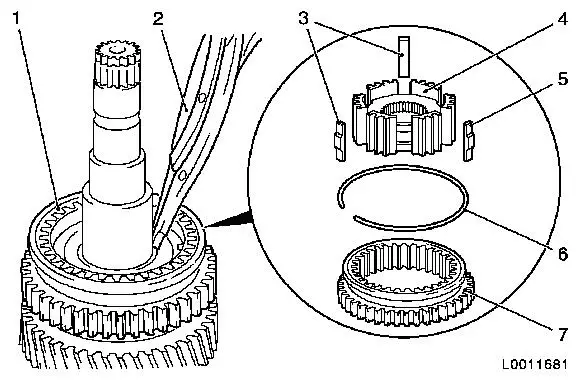

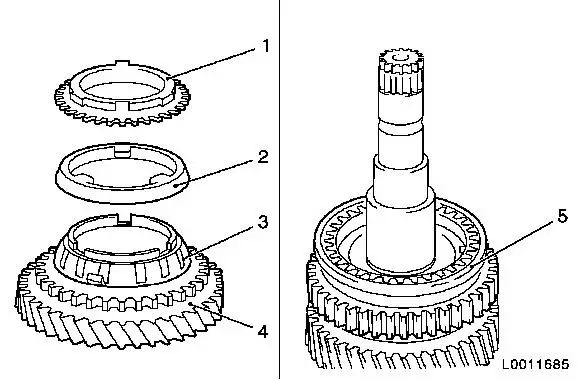

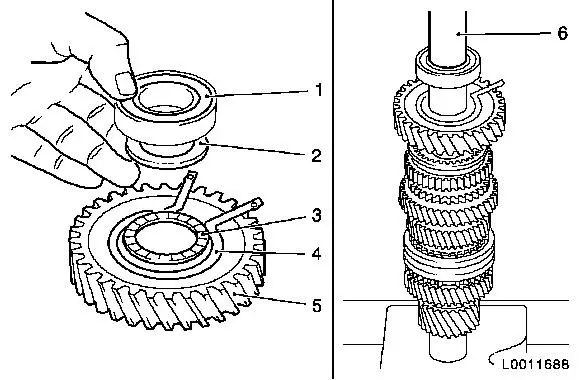

| 10. |

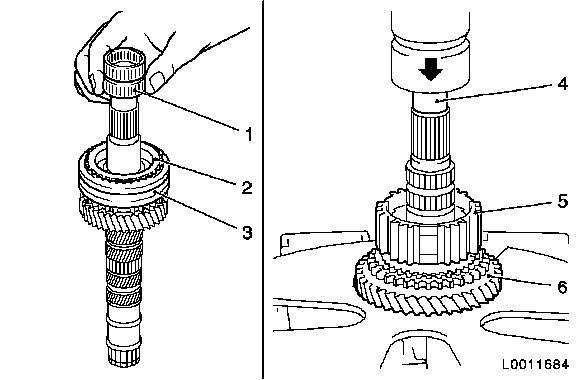

Detach 3x synchroniser ring, gear wheel, 1st gear

| • |

Remove needle bearing (1), inner synchroniser ring (2),

intermediate ring (3) and outer synchroniser ring (4)

|

|

|

|

| 11. |

Detach synchro body (4)

| • |

Detach retaining ring (1) for synchro body 1st/2nd gear

assembly with KM-396 (2)

|

| • |

Detach shift sleeve (7)

|

| • |

Detach synchroniser spring (6)

|

| • |

Detach sliding blocks (3) and (5)

|

|

|

|

| 12. |

Detach 2nd gear (5).

| • |

Press gear wheel, 2nd gear, off main shaft with appropriate

drift punch (6) and KM-307-B (7)

|

| • |

Remove synchro body (1), inner synchroniser ring (2),

intermediate ring (3) and outer synchroniser ring (4)

|

|

|

|

Important: Always replace drive

wheels (driving and driven) in pairs.

|

| 13. |

Detach drive wheel (driving) (3)

| • |

Press drive wheel off main shaft with appropriate drift punch

(2) and KM-307-B (4)

|

|

|

|

| 14. |

Detach 4th gear

| • |

Place KM-307-B (1) in groove with

gear wheel, 4th gear

|

| • |

Press gear wheel, 4th gear, and spacer washer (4) off main

shaft with appropriate drift punch (3) and KM-307-B

|

|

|

|

| 15. |

Detach needle bearing (1) from main shaft

|

| 16. |

Detach synchroniser ring, gear wheel, 4th gear (2)

|

| 17. |

Detach shift sleeve (3) from main shaft

| • |

Remove synchroniser spring and sliding blocks

|

|

| 18. |

Detach gear wheel, 3rd gear (6).

| • |

Press synchro body 3rd/4th gear (5), synchroniser ring and gear

wheel, 3rd gear, off main shaft with appropriate drift punch (4)

and KM-307-B

|

|

|

| 20. |

Check all parts for damage

Note: Replace damaged

components.

|

Install

Install

| 21. |

Immerse all parts in transmission fluid before

installation.

|

| 22. |

Lubricate all bearing bore holes and seating surfaces with

transmission fluid before installation.

|

|

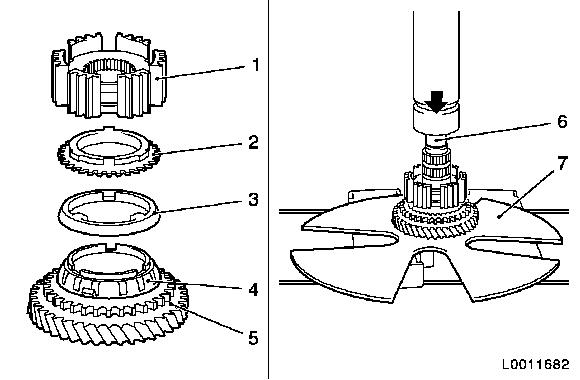

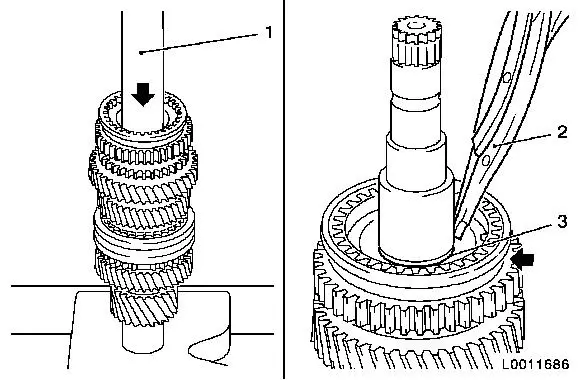

| 23. |

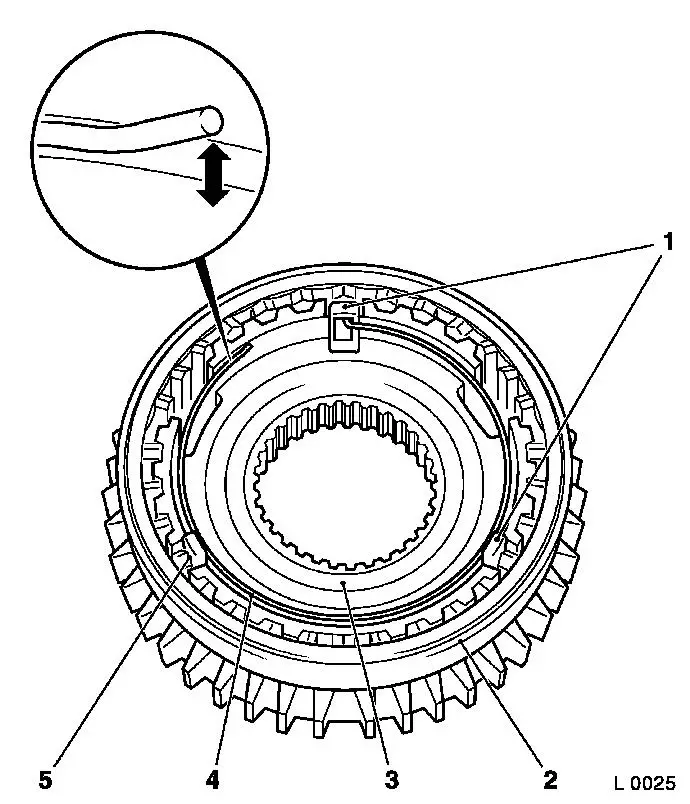

Assemble synchro body 1st/2nd gear and 3rd/4th gear

Note: Synchro body

assembly 1st/2nd gear and 3rd/4th gear can only be pressed onto

main shaft in an assembled state

Overview of Synchronisation .

| • |

Insert synchro body (3) into shifter collar (2).

|

| • |

Insert 3x sliding block (1) and (5)

Note: Insert with the

open side facing the synchro body

|

| • |

Insert synchroniser spring (4)

Note: Ensure that when

installed in the correct position, the free end lifts off the

synchro body (arrow).

If this is not the case, turn synchroniser spring 180° and

reinstall.

Offset end of synchroniser engages in a slide block.

|

|

|

|

| 24. |

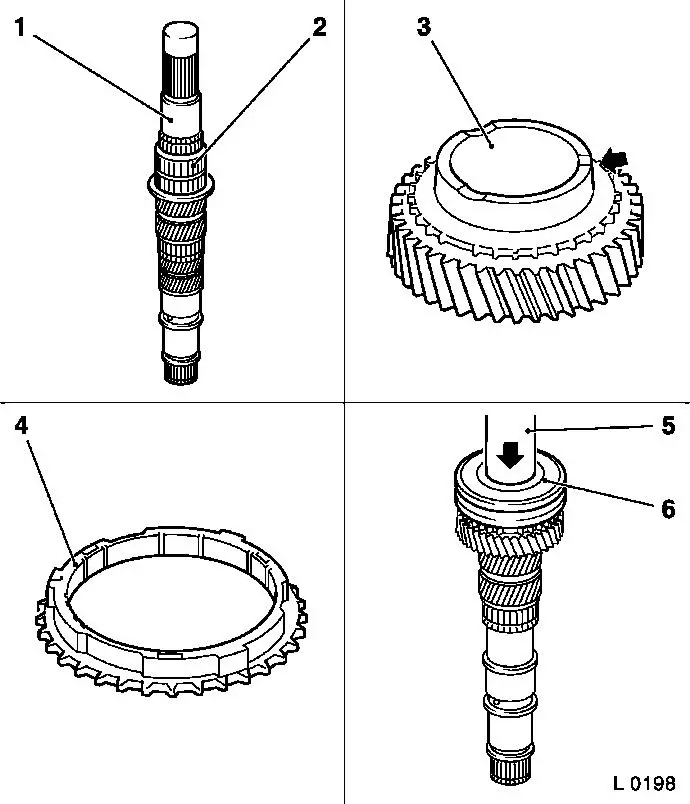

Attach gear wheel, 3rd gear (3), to main shaft

| • |

Attach needle bearing (2) for gear wheel, 3rd gear, to main

shaft (1)

|

| • |

Push gear wheel, 3rd gear, on to the main shaft from the drive

wheel side

Note: Cone (arrow)

points in the direction of the drive wheel

|

|

| 25. |

Press synchro body assembly for 3rd/4th gear (6) with KM-277 (5) onto main shaft.

| • |

Place synchroniser ring (4) onto 3rd gear cone.

|

|

|

|

| 26. |

Attach gear wheel, 4th gear (2), to main shaft

Note: Always replace

drive gears in pairs.

| • |

Attach needle bearing, gear wheel, 4th gear to main shaft

|

| • |

Attach synchroniser ring (3) to main shaft

|

| • |

Attach spacer washer (1) to main shaft

Note: 4x groove

(arrows) points to the gear wheel, 4th gear.

|

|

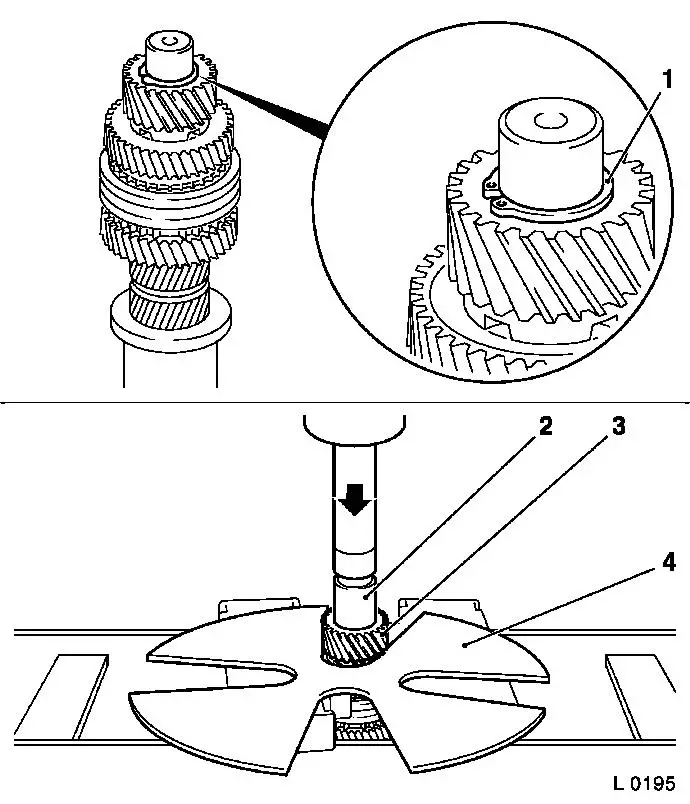

| 27. |

Attach drive wheel (5) to main shaft

Note: Collar points

towards the spacer washer.

| • |

Press drive wheel on to main shaft with KM-311-2 (4)

|

| • |

Attach retaining ring (6)

Note: Use new retaining

ring.

|

|

|

|

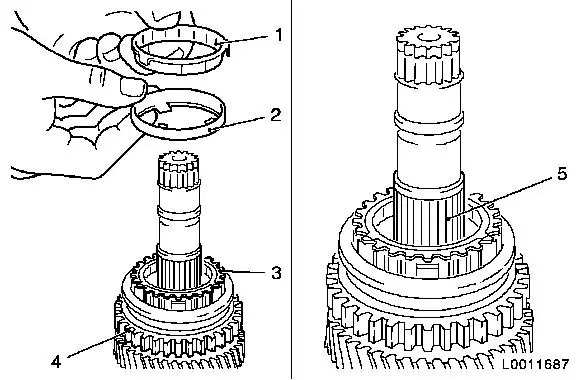

| 28. |

Attach gear wheel, 2nd gear (4), to main shaft

| • |

Attach inner synchroniser ring (3)

Note: Lugs must sit in

grooves of gear wheel.

|

| • |

Attach intermediate ring (2)

|

| • |

Attach outer synchroniser ring (1)

Note: Grooves must sit

on the lugs of the inner synchroniser ring.

|

|

| 29. |

Attach synchro body assembly (5) to main shaft

|

|

|

| 30. |

Press synchro body assembly on to main shaft with KM-277 (1)

Note: Lugs in outer

synchroniser ring must align with grooves in synchro body.

Shift fork groove (arrow) points towards the ball bearing seat

|

| 31. |

Attach retaining ring (3) with retaining ring pliers (2)

Note: Use new retaining

ring.

|

|

|

| 32. |

Attach outer synchroniser ring (3)

Note: Lugs must sit in

the grooves of the synchro body (4).

|

| 33. |

Attach intermediate ring (2)

|

| 34. |

Attach inner synchroniser ring (1)

Note: Lugs must sit in

the grooves of the outer synchroniser ring.

|

| 35. |

Attach needle bearing, 1st gear, (5) to main shaft

|

|

|

| 36. |

Attach 1st gear (5)

Note: Grooves must sit

on the lugs of the intermediate ring.

| • |

Attach axial needle bearing (3)

|

| • |

Attach spacer washer (2)

|

| • |

Fit new retaining ring (4)

|

|

| 37. |

Press ball bearing (1) on to main shaft with KM-334 (6)

|

|

|

| 38. |

Install end shield (2)

|

| 39. |

Attach end shield cover (1)

|

|

Important: Do not damage wiring

harnesses and attaching parts

|

| 40. |

Raise engine and transmission on the left hand side

|

| 41. |

Install front axle body

|

| 42. |

Detach KM-6001-B from front axle

body

|

|

| 43. |

Install gearbox cover (1)

Note: For F13

transmission.

Install gearshift module (2)

Note: For F13 MTA

transmission.

|

| 44. |

Fit reversing lamp switch (3)

| • |

Tighten reversing lamp switch

|

| • |

Connect wiring harness plug for reversing lamp switch

|

|

|

| 45. |

Correct transmission fluid level

|

|