Liftgate Window Replacement (5-Door Wagon 35)

Special Tools

| • |

BO-46974 Glass

Removal System |

For equivalent regional tools, refer to

Special Tools .

For needed amount of one part adhesive, refer to

Adhesives, Fluids, Lubricants, and Sealers .

Removal Procedure

Warning: Refer to

Cracked Window Warning .

Warning: Refer to

Glass and Sheet Metal Handling

Warning .

Note: Position the vehicle

on level ground and move the front wheels to the straight-ahead

position

| 4. |

Disconnect the liftgate window

radio antenna connector. |

| 5. |

Disconnect the electrical

connectors from the liftgate window defogger bus bars. |

| 6. |

Cover the following parts to

protect from the broken glass: |

| 7. |

Use BO-46974

system to remove the liftgate window. |

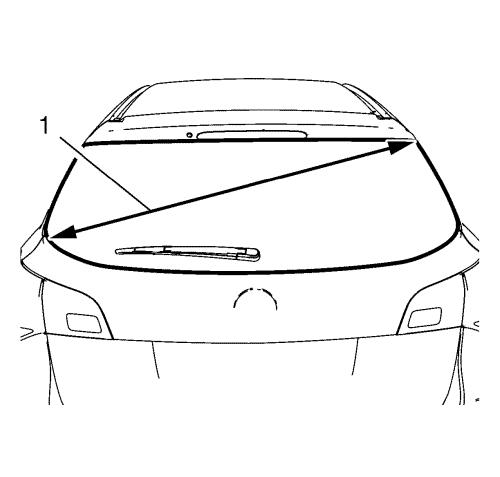

| 8. |

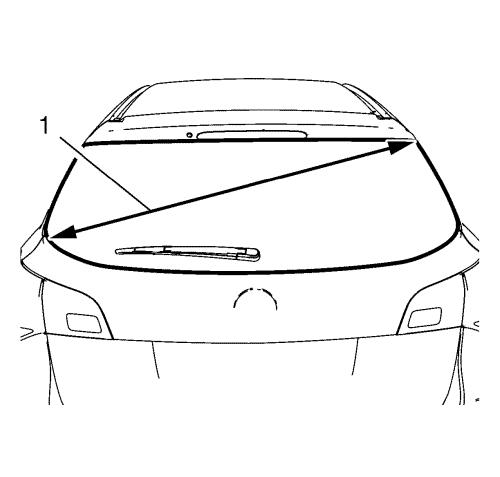

Take the diagonal measurement

(1) of the liftgate window. |

| 9. |

Cut cutting wire into four

times lengths. |

| |

Approximately 5400 mm (212.597 in), the circumference of the

corresponding roll of wire is approximately 1000 mm (39.369

in). |

| 10. |

Heat the awl with a suitable

tool. |

|

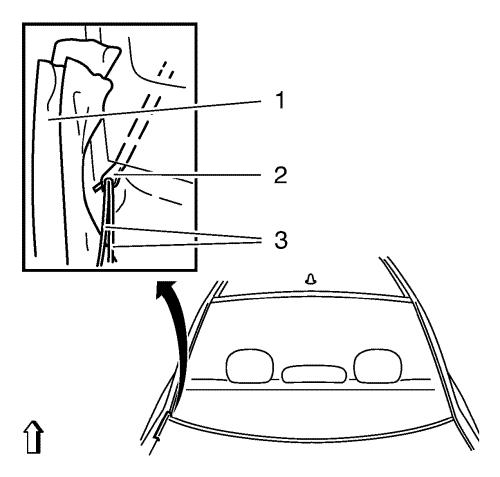

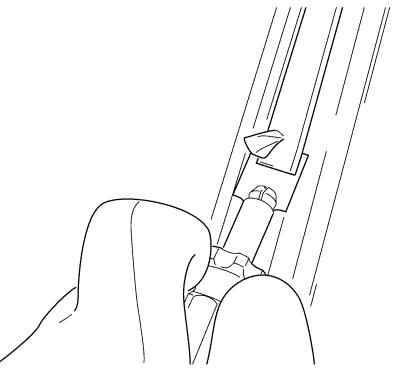

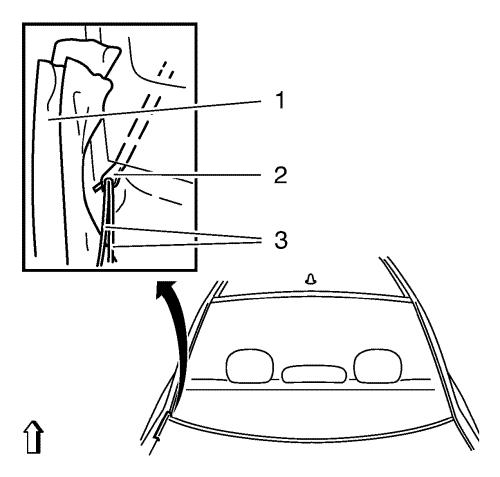

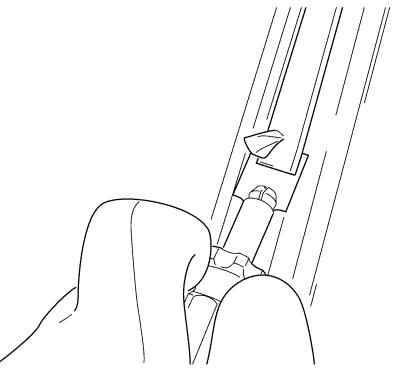

Note: Ensure that the

liftgate window is not damaged in the process. Otherwise, stress

cracks could form in the liftgate window. Mask off the area with

fabric tape (1).

|

| 11. |

Stick the awl (2) through the

adhesive bed in the area of the lower C-pillar. |

| 12. |

Pull the wire through.

|

| |

• |

Thread both ends of the

cutting wire (3) in the bores of the piercing awl (2) and bend

them. |

| |

• |

Use the piercing awl (2) to

pull the cutting wire to the centre of the liftgate window.

|

|

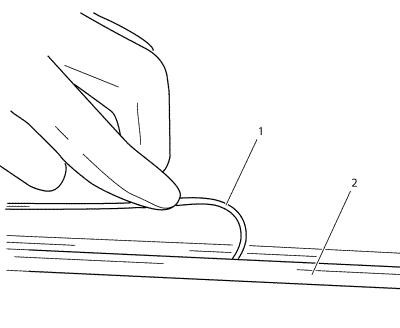

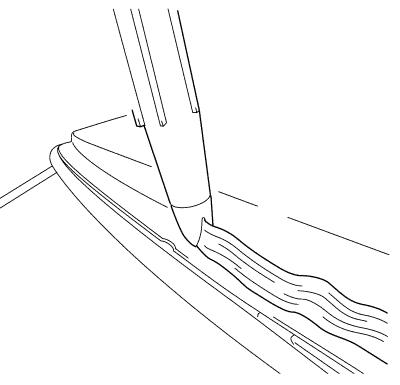

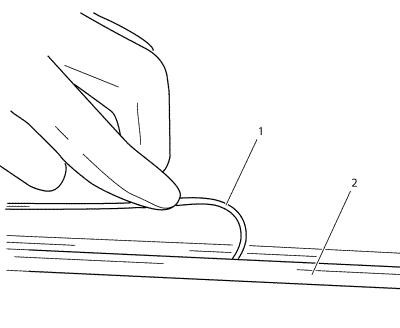

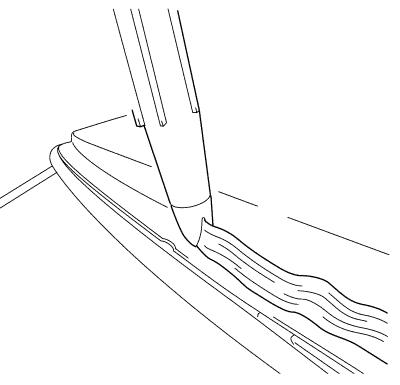

Note: The cutting

wire (1) should be rolled in beneath the rubber window seal (2) at

the liftgate window.

|

| 13. |

Lay the wire (1) under the

liftgate window all the way round. |

| 14. |

Pull the remaining wire into

the interior. |

|

Note: Ensure that the

cutting wire is fitted correctly to the winch deflection

roller.

|

| 15. |

Place the winch with two

winding heads on liftgate window inside. |

| |

• |

Position the winch vertically

at the same height as the C-pillar. |

| |

• |

Attach the cutting wire to the

winch (1). |

| |

• |

Insert transfer ratchet and

pre-tension cutting wire. |

|

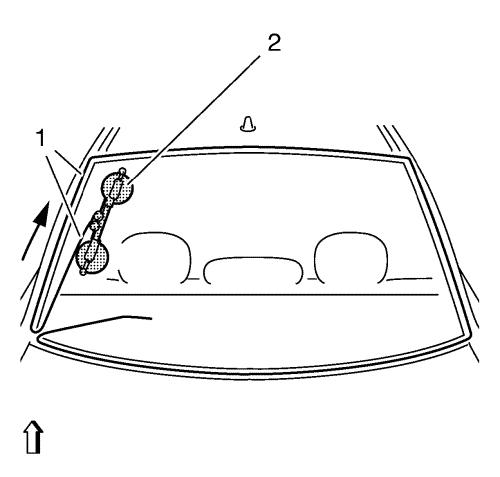

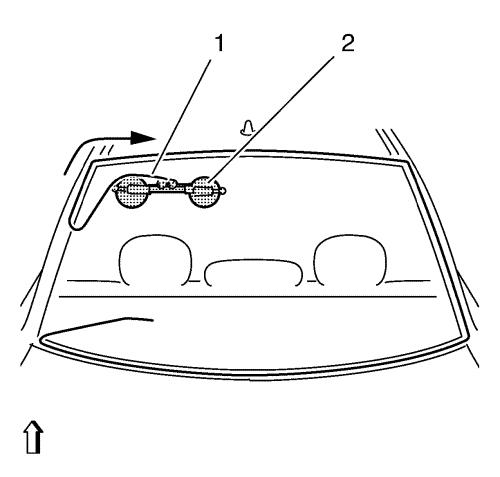

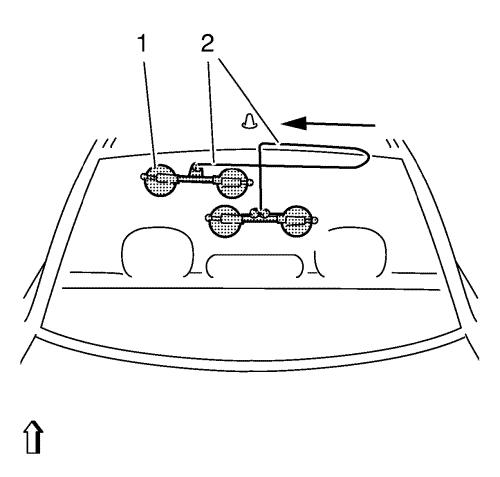

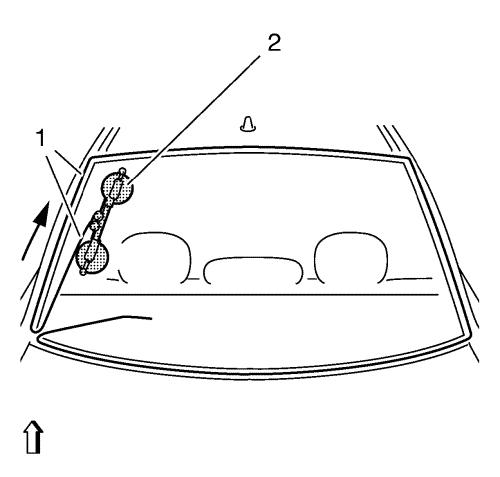

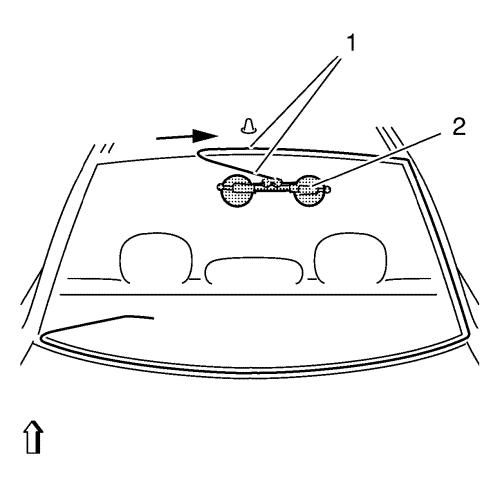

Note: Arrow shows the

path taken by the cutting wire.

|

| 16. |

Cut out the liftgate window

until the cutting wire is level with the winch. |

|

Note: Ensure that the

cutting wire is fitted correctly to the winch deflection

roller.

|

| 17. |

Place the winch with two

winding heads in the vehicle. |

| |

• |

Position the winch (2) in the

area of the roof frame. |

| |

• |

Insert transfer ratchet and

pre-tension cutting wire (1). |

|

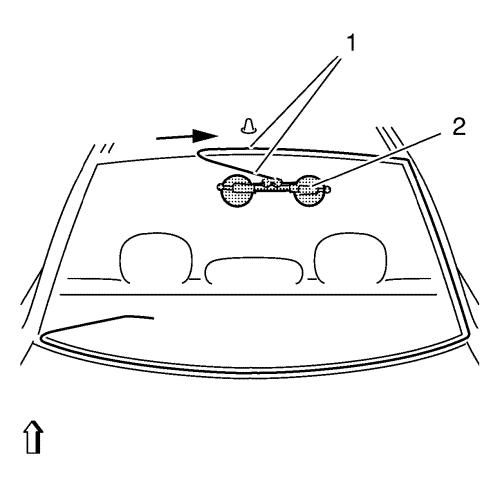

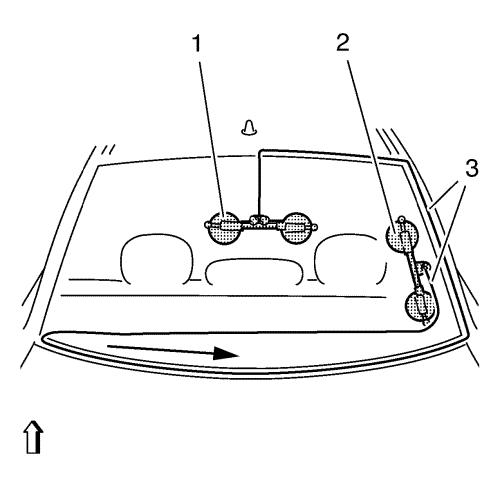

Note: Arrow shows the

path taken by the cutting wire.

|

|

Note: Increased

cutting effort is required in the area of the liftgate window

radius.

|

| 18. |

Cut out the liftgate window

until the cutting wire is level with the winch. |

|

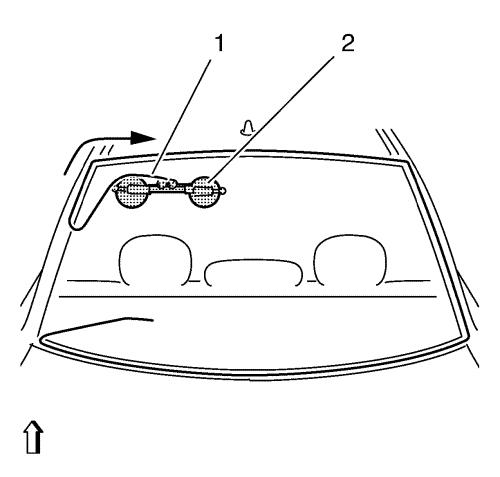

Note: Ensure that the

cutting wire is laid correctly to the winch deflection roller.

|

| 19. |

Place the winch with two

winding heads in the vehicle. |

| |

• |

Position winch in the middle

area of liftgate window (2). |

| |

• |

Insert transfer ratchet and

pre-tension cutting wire (1). |

|

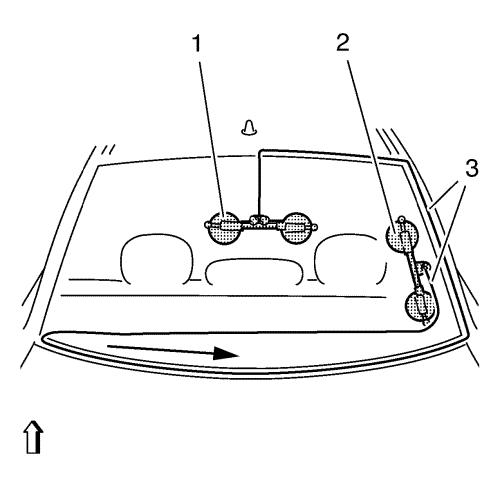

Note: Arrow shows the

path taken by the cutting wire.

|

| 20. |

Cut out the liftgate window

until the cutting wire is level with the winch. |

|

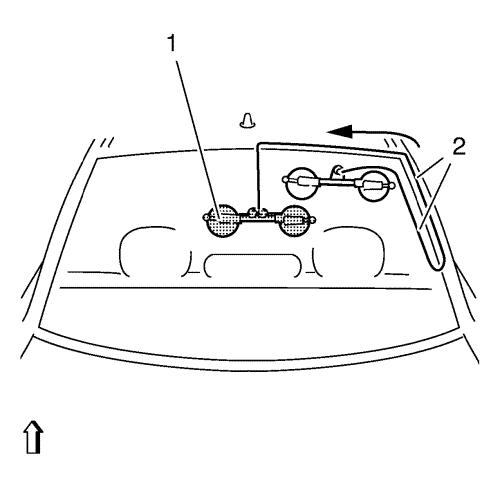

Note: Ensure that the

cutting wire is fitted correctly to the winch deflection

roller.

|

| 21. |

Position the winch with one

winding head on liftgate window inside. |

| |

• |

The winch with 2 winding heads

(1) stays in the position. |

| |

• |

Position winch with one

winding head (2) in the area of the lower C-pillar. |

| |

• |

Thread the second end of the

wire (3). |

| |

• |

Insert transfer ratchet and

pre-tension cutting wire. |

|

Note: Arrow shows the

path taken by the cutting wire.

|

|

Note: Increased

cutting effort is required in the area of the liftgate window

radius.

|

| 22. |

Cut out the liftgate window

until the cutting wire is level with the winch. |

|

Note: Check that the

cutting wire is laid correctly at the winch deflection roller.

|

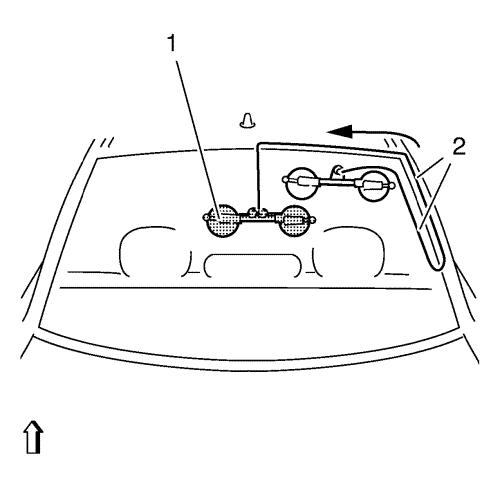

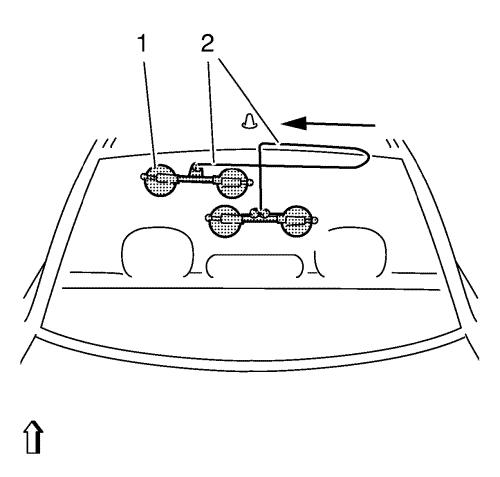

| 23. |

Position the winch with one

winding head in the vehicle. |

| |

• |

Position the winch with one

winding head (1) in the upper area of the liftgate window.

|

| |

• |

Insert transfer ratchet and

pre-tension cutting wire (2). |

|

Note: Arrow shows the

path taken by the cutting wire.

|

|

Note: Increased

cutting effort is required in the area of the liftgate window

radius.

|

| 24. |

Cut out the liftgate window

until the cutting wire is level with the winch. |

|

Note: Check that the

cutting wire is laid correctly to the winch deflection roller.

|

| 25. |

Position the winch with one

winding head on liftgate window inside. |

| |

• |

Position winch with one

winding head (1) next to winch with two winding heads so that the

cutting wire crosses (2). |

| |

• |

Insert transfer ratchet and

pre-tension cutting wire. |

|

Note: Arrow shows the

path taken by the cutting wire.

|

| 26. |

Cut out the liftgate window

until the cutting wire (2) has cut through the adhesive bead

completely. |

| 27. |

Remove glass removal

system. |

| 28. |

Fit and lock BO-641

holder onto liftgate window. |

|

Note: Second

technician required.

|

| 29. |

Remove liftgate window.

|

| 30. |

Cut out the adhesive tape with

the knife provided (1) to within 1 mm (0.039 in). |

| 31. |

Repair any paint

damage. |

| |

Using a touch-up pen to match the color of the vehicle, repair

any paint damage. |

| 32. |

If the liftgate window rubber

is damaged, replace with a new one. |

| 33. |

Cut off the adhesive bead on

the glass pane. |

| |

Cut out the adhesive tape with the knife provided to within 1

mm (0.039 in). |

Installation Procedure

| 1. |

Remove all mounds or loose

pieces of urethane adhesive from the pinch-weld area. |

| 2. |

Inspect for any of the

following conditions in order to help prevent future breakage of

the window: |

| |

• |

Any other obstruction or

irregularity in the pinch-weld flange |

| 3. |

After repairing the opening as

indicated, perform the following steps: |

| |

Remove all traces of broken glass from the outer cowl panel,

seats and floor. |

| 4. |

Apply adhesive bead

(1). |

| |

Cut into the tip of the cartridge in such a way that a bead of

adhesive approx. 13 mm (0.511 in) thick is produced. |

| 5. |

Insert liftgate window.

|

| |

• |

Place the liftgate window at

the upper area and lower down. |

|

Note: Second technician

required.

|

| |

|

|

| |

• |

Insert liftgate window with

BO-641 holder . |

| 6. |

Secure liftgate window in

position with fabric tape. |

| 7. |

Clean any excess urethane

adhesive from the body. |

| 8. |

Use a soft spray of warm water

in order to immediately water test the window. |

| 10. |

If any leaks are found, use a

plastic paddle in order to apply extra urethane adhesive at the

leak point. |

| 11. |

Retest the window for

leaks. |

| 12. |

Maintain the following

conditions in order to properly cure the urethane adhesive:

|

| |

• |

Partially lower a door window

in order to prevent pressure buildups when closing doors before the

urethane adhesive cures. |

| |

• |

Do not drive the vehicle until

the urethane adhesive is cured. Refer to the above curing

times. |

| |

• |

Do not use compressed air in

order to dry the urethane adhesive. |

| 13. |

Connect the electrical

connectors to the liftgate window defogger bus bars. |

| 14. |

Connect the liftgate window

radio antenna connector. |

|