|

Replace bearing in transmission housing (F23)

Remove Remove

| 1. |

Dismantle transmission

|

| 2. |

Check main shaft and intermediate shaft bearing for damage

| • |

If necessary, replace bearing

|

|

|

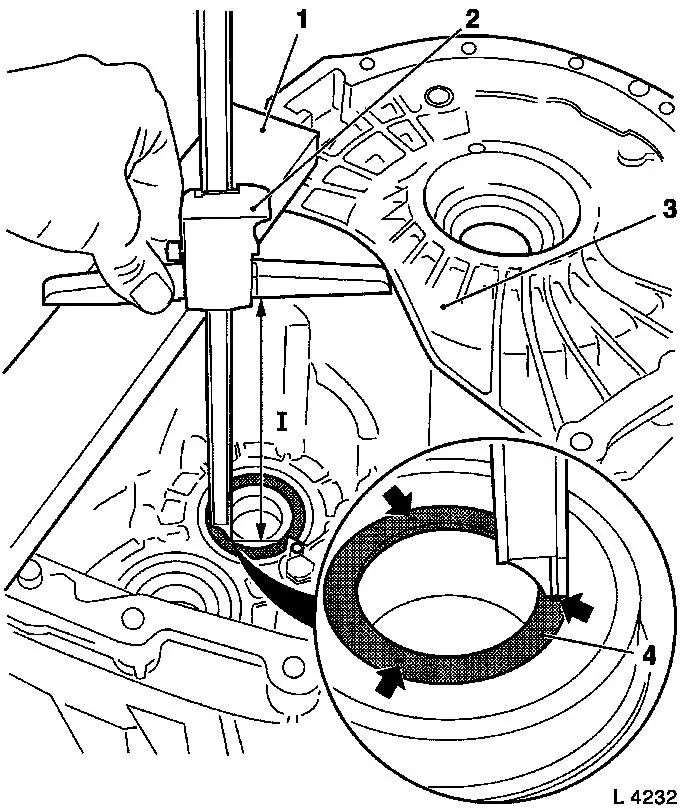

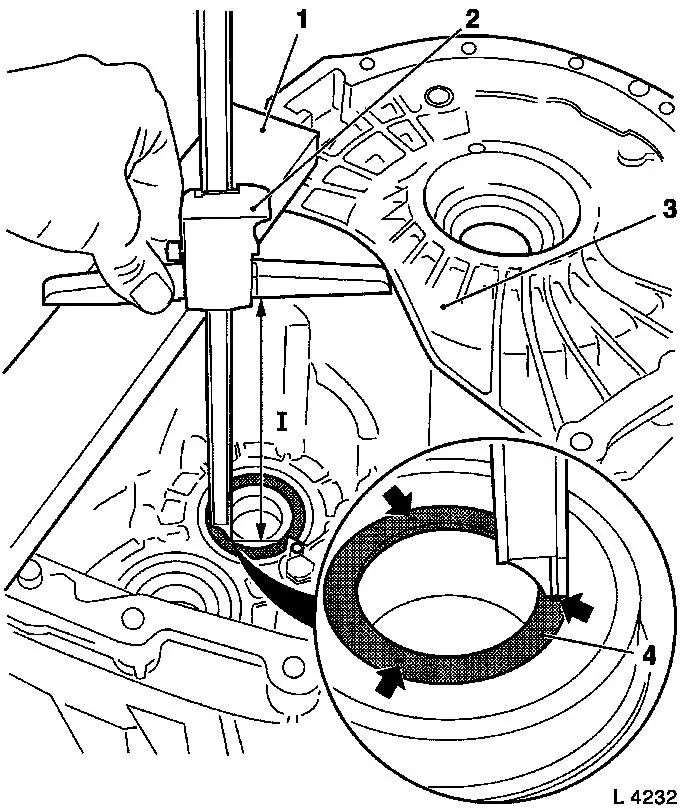

| 3. |

When replacing main shaft bearing: determine installed position

of old main shaft bearing in transmission housing

Note: Ensure that the

main shaft bearing in the transmission housing is not resting on

the workbench during measurement. Support the transmission housing

so that the inner ring of the main shaft bearing hangs free.

| • |

Place KM-621-23 (1) on transmission

housing (3)

|

| • |

Determine distance (I) from inner ring of main shaft bearing to

top edge of KM-621-23

| – |

Use a standard commercial digital depth micrometer (2)

Note: Micrometer range

at least 250 mm, 0.01 mm graduations

|

| – |

Perform measurement 3 times - space measuring points evenly

around inner ring (arrows)

|

| – |

Add all measured values together

|

| – |

Divide by the number of measurements

|

| – |

Note down the average

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Example

=

|

|

|

Your values

|

|

1st measurement

|

187.02mm

|

+

|

1st measurement

|

|

2nd measurement

|

187.06mm

|

+

|

2nd measurement

|

|

3rd measurement

|

187.05mm

|

=

|

3rd measurement

|

|

Total

|

561.13mm

|

:3=

|

Total

|

|

Average

|

187.04mm

|

|

Average

|

|

|

|

|

|

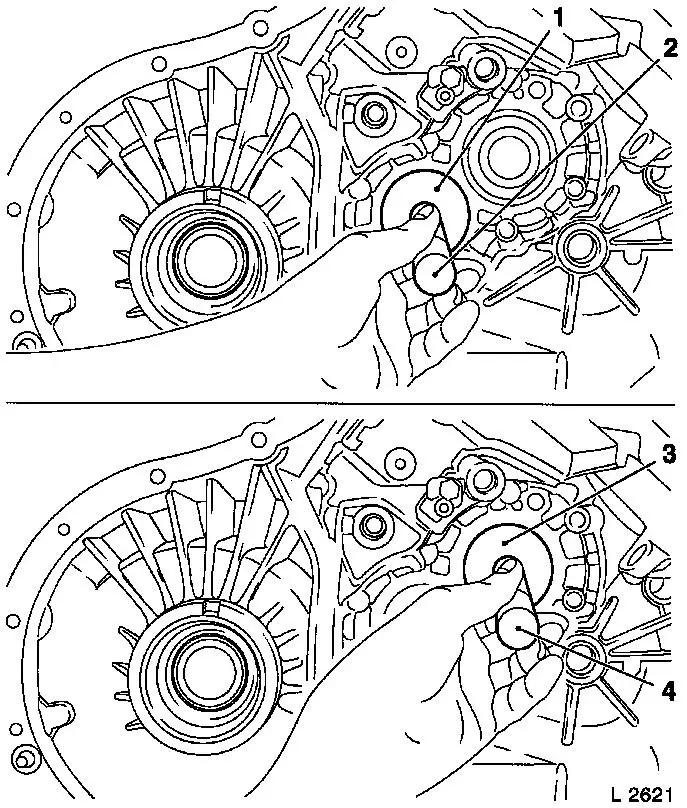

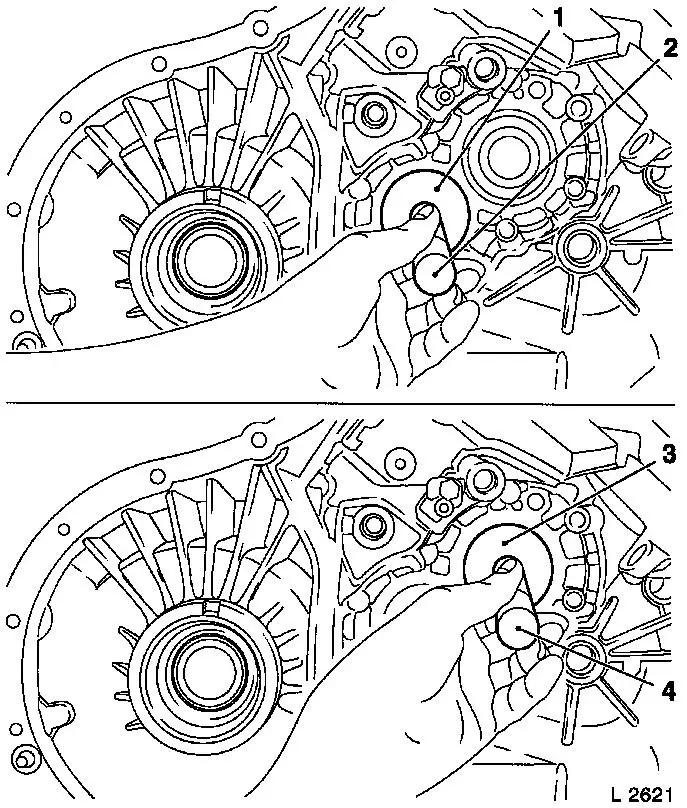

| 4. |

When replacing the main shaft bearing: remove main shaft

bearing from transmission housing

| • |

Knock out with KM-6122 (1) and KM-523-1 (2)

|

|

| 5. |

When replacing the drive shaft bearing: remove drive shaft

bearing from transmission housing

| • |

Knock out with KM-6123 (3) and KM-523-1 (4)

|

|

|

|

| 6. |

When replacing the main shaft bearing: install new main shaft

bearing in transmission housing

| • |

Knock out with KM-6122 (1) and KM-523-1 (2)

|

|

| 7. |

When replacing the drive shaft bearing: install new drive shaft

bearing in transmission housing

| • |

Knock out with KM-6123 (3) and KM-523-1 (4)

|

|

|

|

| 8. |

When replacing the drive shaft bearing: determine installed

position of new main shaft bearing in transmission housing

Note: Ensure that the

main shaft bearing in the transmission housing is not resting on

the workbench during measurement. Support the transmission housing

so that the inner ring of the main shaft bearing hangs free.

| • |

Place KM-621-23 (1) on transmission

housing (3)

|

| • |

Determine distance (I) from inner ring of main shaft bearing to

top edge of KM-621-23

| – |

Use a standard commercial digital depth micrometer (2)

Note: Micrometer range

at least 250 mm, 0.01 mm graduations

|

| – |

Perform measurement 3 times - space measuring points evenly

around inner ring (arrows)

|

| – |

Add all measured values together

|

| – |

Divide by the number of measurements

|

| – |

Note down the average

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Example

=

|

|

|

Your values

|

|

1st measurement

|

187.02mm

|

+

|

1st measurement

|

|

2nd measurement

|

187.06mm

|

+

|

2nd measurement

|

|

3rd measurement

|

187.05mm

|

=

|

3rd measurement

|

|

Total

|

561.13mm

|

:3=

|

Total

|

|

Average

|

187.04mm

|

|

Average

|

|

|

|

|

| 9. |

Calculate the dimensional difference between the installed

positions of the new/old main shaft bearing inner rings

| • |

Calculate the difference between the averages

| – |

Subtract the average noted down for the new bearing from the

average noted down for the old bearing

Note: If the difference

exceeds +0.02/-0.06mm, the pressure collar must be adjusted.

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Average for old bearing

|

187.04mm

|

-

|

Average for old bearing

|

|

|

mm

|

-

|

|

Average for new bearing

|

187.16mm

|

=

|

Average for new bearing

|

|

|

mm

|

=

|

|

Difference

|

-0.12mm

|

|

Difference

|

|

|

mm

|

|

|

|

|

|

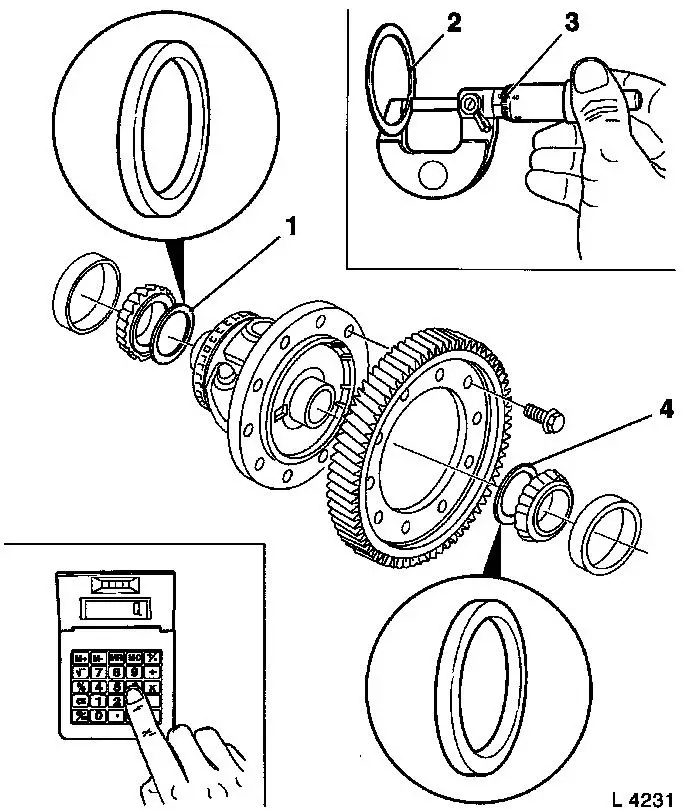

| 10. |

If necessary, reset pressure collar

| • |

Remove differential gear tapered roller bearing

|

| • |

Replace 2 shims (1) and (4)

Note: If the

dimensional difference is positive, a shim (4) that is thicker by

the same amount must be selected at the transmission housing side.

If the dimensional difference is negative, an appropriately thinner

shim must be used. The total thickness of the two shims (1) and (4)

must remain constant, since they determine the pretension of the

differential gear tapered roller bearing. For this reason, when a

thicker shim (4) is used at the transmission housing side, a shim

that is thinner by the same amount must be installed at the clutch

housing side (1). When a thinner shim is used at the transmission

housing side an appropriately thicker shim must be installed at the

clutch housing side.

Note: The shims can be

obtained from "Aftersales". The thickness of the shims (2) must be

determined with a micrometer (3) as they are not marked.

Note: The table below

contains a few examples from the range of shims that can be

supplied. When adjusting, the shims must be selected to achieve the

smallest tolerance possible. Undamaged used shims can be

re-used.

|

Difference in dimensions

|

Shim (on transmission housing side)

|

Shim (on clutch housing side)

|

| |

old

|

new

|

old

|

new

|

|

+ 0.25mm

|

0.90mm

|

1.15mm

|

0.75mm

|

0.50mm

|

|

- 0.20mm

|

0.90mm

|

0.70mm

|

0.75mm

|

0.95mm

|

|

- 0.13mm

|

0.90mm

|

0.75mm

|

0.75mm

|

0.90mm

|

|

-0.12mm

|

0.90mm

|

0.80mm

|

0.75mm

|

0.85mm

|

|

|

|

Install

Install

| 11. |

Install differential gear tapered roller bearing

|

| 12. |

Assemble transmission

|

|