Corsa D

Field Remedy: 2761

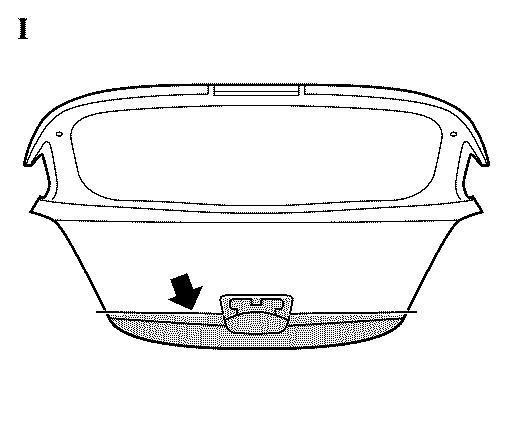

Remedy:In case of customer complaint grind the paint in the area of corrosion down to the uncoated metal sheet and perform a paint repair stage III (as described in TIS2Web). See Working Procedure “Paint Stages”, Group “B – Paint/Painting Repair System”, Service Instruction Corsa-D. Note: If the listed chemical products are not available in your country, use usual equivalent available products (same specification) (egg. Sikkens 2K Primer Surfacer EP II). Working Procedure: Note: If there are several corrosion dots in the lower aera at the tailgate (arrow) grind and repair the complete lower tailgate area (Picture I). Note: Picture I shows body style L68.

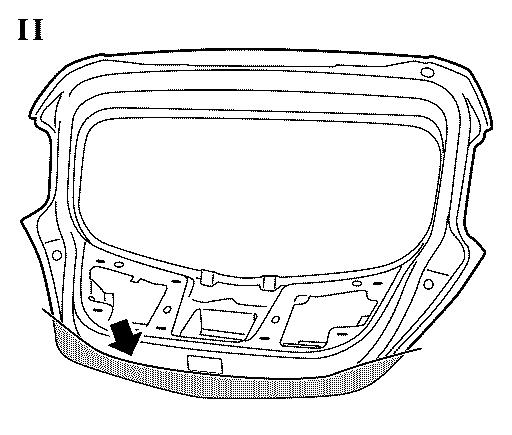

Important: Remove the original sealing at the lower inner area at the tailgate (arrow) only if there are corrosion dots present (Picture II)!

1. Clean outer repair area at tailgate Warning:

Pay attention to the safety regulations!

Arrange appropriate inhalation protection!

- Use antistatic/Silicon remover (93165067 / 15 30 040)

- Post-clean using degreaser – solvent-free –

(93165312 / 65 30 017)

2. Grind outer repair area at tailgate - Remove paint including zinc coat using an orbital grinder

and grinding disc (P40-P120)

3. Grind lower/inner repair area at tailgate (Picture II, arrow) Warning:

Pay attention to the safety regulations!

Arrange appropriate inhalation protection!

Important:

This work step is only required if there are corrosion dots at

the lower/inner tailgate area!

If there are NO corrosion dots in this area, the original sealing

may NOT be removed!

- Remove paint and zinc coat completely at border edges, folding,

swage lines, edges, sealing seams, sealing compounds using an

angle grinder and a pigtail steel brush, Roloc Bristle Disc or

something comparable

- Rework repair area using an orbital grinder and grinding

disc (P120)

4. Clean repair area using degreaser – solvent-free –

(93165312 / 65 30 017)

5. Filler repair area Important:

For the filler coat the lower specified 2K EP priming filler

MUST be used !

- Priming filler with 2K EP

93165239 / 15 30 121,

93165240 / 15 30 122,

90009260 / 15 30 181 or

90369080 / 15 30 172

- Mixture ratio: Grinding version

100 parts by volume 2K EP priming filler

50 parts by volume hardener for 2K EP priming filler

40 parts by volume general-purpose thinner V85/long

- Apply 3 running single coats

- Nozzle size: 1.8 – 2.0 mm

- Injection pressure: According to the manufacturer specifications

Note:

Flash off time 5 – 10 Min. at 20°C

6. Dry repair area Note:

To guarantee a complete drying process medium till short wave

infrared devices should be used.

Alternatively an oven drying of 40 Min. at 60°C may be performed.

Important:

At temperatures below 15°C drying MUST be performed with an oven

respectively with an infrared heating element!

7. Grind repair area (dry) - Using grinding disc (P400 – P500) Important:

Do NOT grind trough the edges!

After grinding a dry coat thickness of at least 80 µm MUST be

present!

Note:

Check folding and edges for too thin grinded areas.

If required repeat step “4” to “6”.

8. Apply sealing compound to border edges - 90093639 / 15 04 520 9. Clean repair area using degreaser – solvent-free –

(93165312 / 65 30 017)

10. Painting - Water-based paint and clear coat or

- VOC finish paint

Spare-Parts: Part-No.: Catalogue-No.: Remover, Anti-static/Silicone 93165067 15 30 040 Cleaner, 5 Litre 93165312 65 30 017 2K EP Filler, 3 Litre 93165239 15 30 121 Hardener, 1 Litre 93165240 15 30 122 Thinner, 2K, 1 Litre 90009260 15 30 181 Thinner, Long, 5 Litre 93165381 15 30 130 Compound, Sealing, 310 ml, 90093639 15 04 520 Vehicle outer side, white (Cartridge) Labour Times: A) Grinding – Tailgate: TC: Hours: U3 276 10 Grinding Paint and Zinc Coat – 90 0.2

Tailgate (outside only)

U3 276 10 001 Tailgate (additional only) 0.4

B) Painting (Paint Stage III): TC: MO AP NAP B 0018 31 Tailgate Below Exterior - 20 1.4 0.2 0.3

Handle, Outer – L08

(One-coat Paint)

B 0018 31 Tailgate Below Exterior - 20 1.5 0.2 0.4

Handle, Outer – L08

(Two-coat Paint)

B 0018 31 Tailgate Below Exterior - 20 1.3 0.2 0.3

Handle, Outer – L68

(One-coat Paint)

B 0018 31 Tailgate Below Exterior - 20 1.4 0.3 0.4

Handle, Outer – L68

(Two-coat Paint)

B 0018 26 Tailgate Below Exterior - 20 1.5 0.2 0.4

Handle, Outer Including

Inner Side – L08

(One-coat Paint)

B 0018 26 Tailgate Below Exterior - 20 1.6 0.3 0.5

Handle, Outer Including

Inner Side – L08

(Two-coat Paint)

B 0018 26 Tailgate Below Exterior - 20 1.4 0.2 0.3

Handle, Outer Including

Inner Side – L68

(One-coat Paint)

B 0018 26 Tailgate Below Exterior - 20 1.5 0.2 0.4

Handle, Outer Including

Inner Side – L68

(Two-coat Paint)

Abbreviations: TC: Trouble Code MO: Major Operation AP: Adjacent Part NAP: Non-Adjacent Part The costs for this repair will be covered during warranty and policy. For policy please refer to the Policy Guideline (WebPG/Kuugel). The regular Warranty Procedure will apply.

|

||||||||||||||||||||